I think if several builders, Paragon and White Ind all came to Park then reamers would get made!

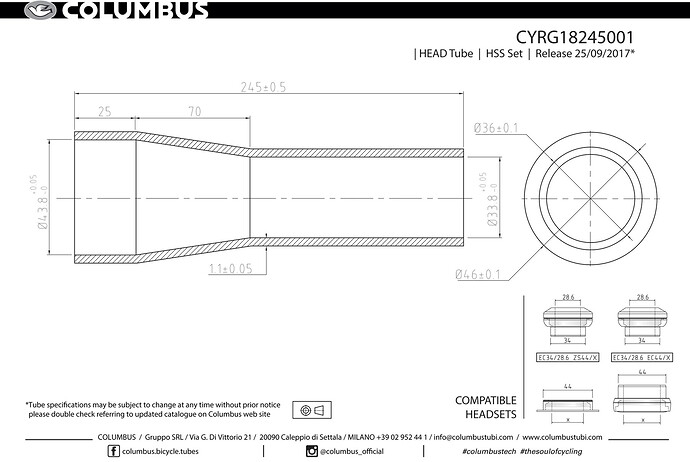

1mm is just the reduced wall thickness in the center section, the section that gets reamed and has the cups pressed in will be quite a bit thicker. Columbus headtubes are a swaged tube and have a constant wall thickness.

Right, 1 mm is the center section. The wall thickness at the ends is 2 mm, which we feel is robust, and eliminates the need for an additional reinforcing ring.

is there also a way to place a zs44 on the downside of the headtube? to make a integreated headset on the fork side…?

A ZS44 only works with a 1.125 bottom race. You also need to design specifically for this, since the EC44 cup vs ZS44 cup is ~12mm of stack difference.

I got some IS41-IS47 from paragon, because they look amazing (in my opinion) and generates a well proportioned frame composition (28,6/31,8 tt and 35/38DT) (again in my opinion…)

but i feel that both IS41-IS47 are a bit of weird standards… (also in my oipinion… ![]() )

)

in the case is IS41 seems more like an american standard, and my issue is now to get the reamer… I know that investing in Park tools reamer is never a bad investment, but i could eaily and much cheaper get a IS 42 (that actually already have…)

So… my question, maybe @mark_pmw can answer… did anyone reamed these headtubes to become a IS42? Do you think its possible??

It may be possible to ream to 42 mm. That’s at the builder’s discretion. Is the rider a 100 kg bull, or a 55 kg ballerina? Rider weight and intended use must be considered as well as the wall thickness and strength of material.

Any builders have experience with this?

Thanks!

They are all below 90kg… and the use is Gravel/All road… nothing crazy…

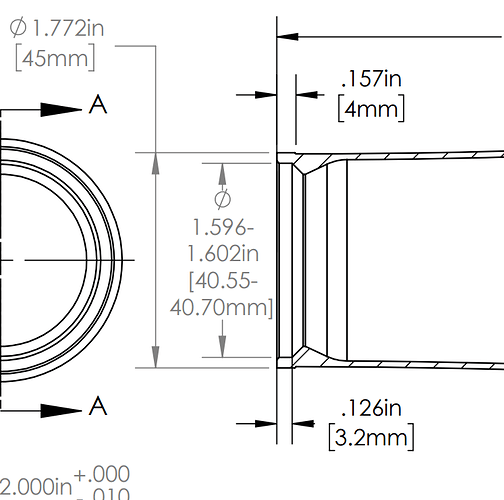

From what i see the wall thickness will be about 1,7mm = (45.1 - 41.7)/2 … It seems thick enough… specially in such a small area… and that’'s why I’m considering this option…

Technically the bearing rests on the 45deg tapered section and does not contact the “walls” of the headtube. The tapered section is much stronger:

Yes… also that!!

For now i do not find any reasons for not trying it… ill keep posted when its done!

Prepare for a good workout

That is true… but ill probably run over the lathe first… and the tapered part will keep tapered…

… I really don’t like that whole idea, and am still 50/50 over doing it. Have 5 of them…

… is 300e in a tool or 300 on other tools… ![]()

Someone knows how to handle the Columbus hss spirit headtube in lightweight version? Wall thickness on top is only 0,9mm but insert for is 42 has an od of 44mm. So there is missing 0,2mm… any experience what to do? I thinking about to lathe my own bearing seat on top… but mane someone knows the magic?

nope… 56mm at the bottom and 46mm at the top. so it is ID 44,2. But i solved the problem:)