Check out Kris at 44 bikes on his insta for jig ideas

Thanks for all the help so far everyone. I’ve got some tubes on hand and am ready to finalize my design. I got the custom downtubes bent and just need a few more bits before I start building.

Some questions about my seatstays:

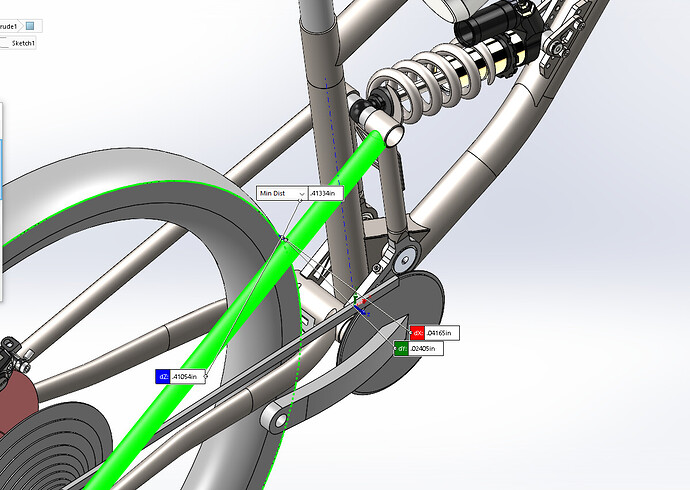

- My very first design had very little tire clearance on the seatstay for a 27.5x2.4. I keep moving the seatstay (and thus the shock pivot mount) outward for more clearance. I think a have enough clearance now (about .41in or 10.4mm) . See below:

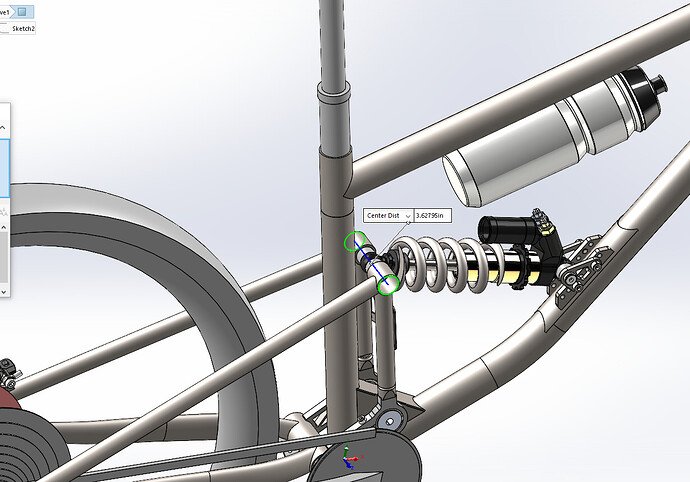

- Because I have moved the pivot boss outward it is now sitting at about 3.63in (92mm) wide. I measured a few of my full suspension bikes and they are both a fair amount thinner a the shock mount. I am worried about hitting my legs on the bosses. Does anyone have some anecdotal numbers to show if this width is too much?

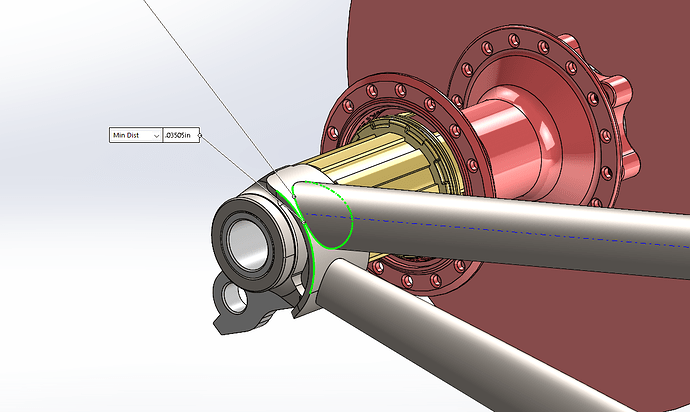

- Lastly, on my Paragon dropouts I have very little width margin on the hooded section for my .75in dia seatstays abut .035in (1mm). I thought that these dropouts were meant to accomodate .75in dia tubes but I’m worried about out the edges of the hood when welding. Have others encountered this? I am thinking I will squish the end of the tube to ovalize before mitering so I have more margin. Should I fillet braze this anyway? Getting the weld in between the seatstay and chainstay looks hard.

Should have plenty of clearance on the seat stays, I aim for 5mm minimum. I don’t have any anecdotal evidence but my first full suspension was about that width and I didn’t notice it much riding apart from the occasional calf graze. Welding to those dropouts is tricky but definitely doable, squishing the tube ends will definitely help

Maybe you tape some cardboard on your existing bike to see if your calves hit the frame? Why not put a bend in the CS to clear the tire?

A few companies make 19mm tapered stays that will give you more space on the dropout

The zona is pretty thin, .6mm thick

Faring has a few options:

Thanks for the input. I pushed the seatstays back inward. I have about 6-7mm of seatstay and chainstay clearance on the rear tire.

Daniel,

Good questions. I will play around with pedaling on some of my current bikes. I was hoping to keep the chainstays really simple with .75x.049 straight gage tubing.

If I use the unbent straight gage I can miter my tubing easily without a stay mitering fixture (which I don’t have). For the chainstays I will build something out of 80/20 and 3D printed stuff and struggle through.

I could use the tapered Zona stays or similar. I specced .049 wall originally because I was worried about laterial rigidity in the rear triangle. I have also ovalized (squished) tubing for more clearance in the past (got that from a Paul Brodie video) I think it works well.