Waltworks waltzing in here with the definitive answer. Chapeau!

I personally add reinforcing rings to all headtubes for a few reasons;

- It cleans up the transition from the headtube to the headset cup

- Adding ~30g to the headtube isn’t as noticed in the overall frame weight while a headtube failure is definitely noticed

- Additional reinforcement at the edges helps to keep the headtube round when brazing or welding to it which is very helpful especially when starting out

- I never want the failure mode of a frame to be at the front end

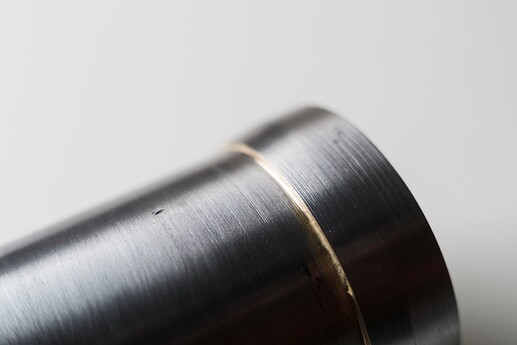

A little while ago I put together some details of what I do for headtube rings and that write up can be found here. This was before the design was finalized so take the actual ring profiles with a grain of salt. Since then I still machine all of my headtube rings so I can control the fit and finish of them. I also machine them slightly oversize of my final dimension so I can go back in and machine them to the final dimension after brazing.

I also add in some details like axially filed grooves to help with wetting out the joint and some punch marks to get the fit dialed for fixtureless brazing.

Post-machining of the HT ring also makes the final product look pretty good before powdercoat/paint which always helps your final finish.