A flat hood introduces another angle that we have to nail. A round hood is more forgiving and it already works with most builder’s workflow who use hooded dropouts.

OK, that’s another point in favor of an entirely round dropout.

The assymetry doesnt bother me. It’s easy enough to build around. The width of the hoods is what I don’t like. It just ends up being a lot of visual bulk but I get why people like usung them.

My opinion: the straight cut would take away a lot of the advantages of the hooded dropout:

- self fixturing

- holesaw workflow

- accuracy

- aesthetics

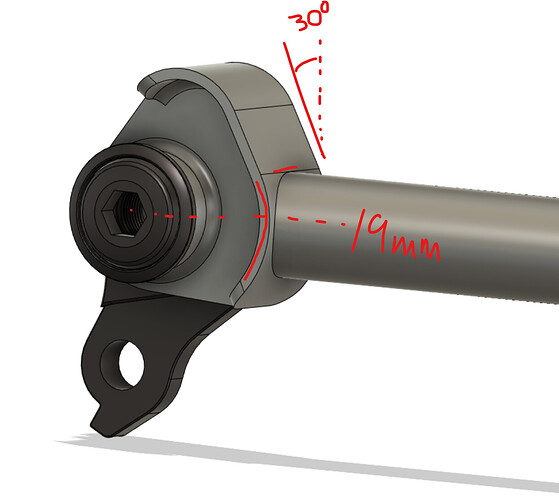

I angled the flat part of the hood back 30deg such that a .75in chainstay should hit the dropout without encountering the flat section (YMMV)

We could do two versions, one for tapered stays, narrow hood, and one for straight stays, wide hood.

That’s two opinions against a flat chainstay mount, that’s enough for me to drop the idea.

@Daniel_Y @manzanitacycles @DEVLINCC @jeremy

Our problems are solved! Carl at Metal Guru Nation has UDH dropouts, with and without eyelets.

They are cast, and the eyelets take them out of the actual UDH spec, but they are available now for less than we can sell them.

Question: Are builders willing to pay far more for a CNC version? Advantages are they will be made from bar stock, so they’ll likely have better welding properties, and precision features like the 20 mm bore will be within SRAM’s tolerance. Perhaps an esthetic advantage, but that’s subjective.

IMO, we don’t use that style of dropout because they only look good on mountain bikes with very shallow SS angles (<40deg). All our MTB’s come with bottles > taller ST > larger SS-CS angles.

Rewind to the original premise of the UDH - Standard or Scam? thread, from all the designs I have done, I was unable to find a mass-producible solution for UDH and metal bikes ![]() . Each design has a pretty big compromise:

. Each design has a pretty big compromise:

- ugly

- heel clearance

- large

- asymetric

- hard to build around

- heavy

- expensive

Maybe it’s so hard to design a good solution because there is no solution ![]()

The hooded plate is the only design that I would feel comfortable putting on our bikes. To be clear, this is all my opinion based on the style of MTB’s we build.

Again, not sure I would use this style. I would have to see what technical advantages the new derailleurs bring to justify the hit to aesthetics. But I would add other benefits to the CNC version:

- documentation

- reliable supply

A new PMW UDH:

I think we can do OK on ugly, but that’s subjective.

They will be large, but that’s subjective.

Heel clearance can be a problem, but less so with tapered stays.

They will be symmetric.

Symmetry will make them easier to build around.

They will be heavy.

They will be expensive.

I’m giving us a score of 7-1/2 out of 10, including the 3 points below. If this were the NBA, we’d be in the playoffs.

Your last two points are valid, documentation and reliable supply. To that, I’ll add better quality welds. All in all, probably makes the expense worth it to enough builders to justify us making some.

We’re going to start designing what we think is the best possible dropout, and post some pics when we get there. Hopefully it will be a good enough solution.

This is very true. There is a lot of asymmetry in chainstays when using a yoke, if it’s functional asymmetry is ok with me! Elevated or dropped drive side chainstay are other examples. Flat mount can make us bend asymmetrical chainstays too.

But since the thread is already past that issue I just like symmetrical dropout hoods cause it’s easier to remember the process and not have two miter lengths - even if it is just a hole saw swap I still do one tube at a time. Would be nice to have a fixture I can setup on the mill for mitering the dropout end of the stays but I don’t.

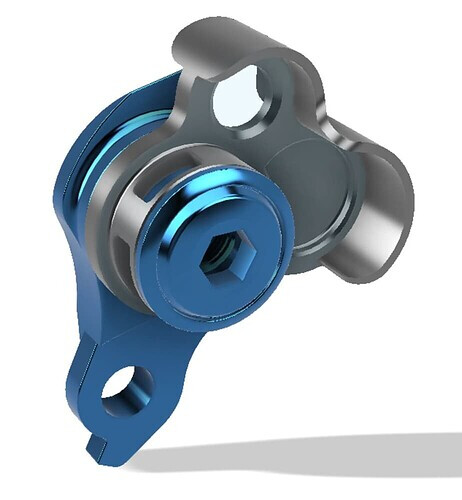

I really like the look of @Daniel_Y hooded slider looking one. Looks cool and can reduce weight functionally (clearing the overly big UDH hanger shelf). It also could be adapted to Ti with a wider hood and not increase the “dropout Q-factor. “

I really don’t want to use the UDH but I disliked flat mount too… so be it.

Thanks @mark_pmw for being here and involving us in the design process!

Any potential for a stainless version or would that be to cost prohibitive? I’ve been wanting to make UDH an option on our hard tails - thanks everyone for starting this conversation!

I think stainless is best for a steel frame, there are no issues with paint or corrosion. They do cost more, but a lot less than wrecking a brand new paint job. I’ll make sure our design can accommodate stainless steel as well.

I don’t know why SRAM thought it was necessary to make the UDH so elaborate. All of their design objectives could have been satisfied with a more simple and compact design.

Update: We are working on a design that meets all the elements above. The most important thing is meeting all of SRAM’s specs.

The second requirement is that it needs to be cosmetically appealing. Our question to frame builders is: What will the ultimate shape be?

ie. Round, like this:

Or Triangular, as in Daniel’s design:

Or, lastly, a lobed shape as in Manzanita’s design:

No matter what the shape, our goal is for it to be as builder friendly as possible, meaning complete symmetry.

Please comment your thoughts. We want to get rolling on a finalized design asap.

Thanks,

Mark

I like whatever will be the lightest and most compact with room for 19mm chainstays and 16mm seatstays. It looks like Daniel’s design does that. The flat bottom of the design allows builders to easily clock the dropout. It’d also be nice if the chainstay miter isn’t offset from the axle center, but that’s not a deal killer.

I made a new lobed version that’s more compact:

It’s similar to Daniel’s design, but with lobes ![]()

The round option is bulkier and likely a lot heavier even if it’s the cheapest option. I’d rather pay more for a smaller design.

I think the triangular shape with a little bit of styling inspiration from the sliders could look pretty cool:

Totally my opinion, but the aesthetics of the new SRAM stuff is very angular and “modern”, so it would suit a similarly styled dropout.

Visually I like the “triangular” look the best, but I think the round would be simplest to miter and pay for. I’m on the fence. I could be happy with any of them honestly, but I would prefer not to have to change hole saw diameters for the CS and SS miters like we do with the flanged Sliders. Even though I’ve made a lot of frames with those dropouts I STILL have to look on the website to remember what diameter saw to use for each ![]()

2 posts were merged into an existing topic: UDH - Standard or Scam?