What does your fork look like? There can be some clever places to put the two top mounts if you have a fork crown.

It is the unicrown one in the first post (Salsa Cromoto grande that I am modifying). Was going to try and avoid drilling into the blades and just go the hourglass route, but I’ve got a drill press and appropriate bits and bottle bosses if that works out to be a better route.

I don’t have anything to add really but think the hourglasses are best for the Surly rack since once you get the rack in hand you can really dial in where they best fit with the lower bosses, basket height above the tire, all that stuff. Put the biggest tire you’ll use on and mock it up in the stand. It’ll become apparent where stuff needs to go.

If others have had good luck with silver that’s great, but if you’re adding a lot of weight to the rack I’d go with bronze. Maybe 48 silver is plenty good for hourglasses with a 4 point attachment, I really don’t know. On an early frame of mine I had used silver to braze on eyelets to stainless tab dropouts and a bike shop tech was mounting a Tubus Airy rack tried to align it so there was equal space on either side of the tire… he used some force and one eyelet ripped off. Now I tig eyelets onto stainless dropouts if they don’t have them integrated (i.e., PMW Sliders).

Thank you to everyone for the help and advice. As mentioned, like suggested I decided to wait until I got the rack. So glad I did that! Going to share my progress below since I am still brand new to this, if anyone has any feedback.

I had to decide between the hourglass mounts and the bottle bosses. In particular for the mid fork mount. Both could have worked but ultimately I decided that I wanted to go with the hourglass style. I figured I could avoid putting a hole in the tube, and also create a nice little fillet on them.

First, I dialed in the fit of the mounts since these come ready to work well on chainstays. Managed to get a nice gapless fit up. The midfork ones were easy. The ones on the bend at the crown were a little more challenging. I used a half round file on an angle that I eyeballed then tweaked the high spots to fit.

Before:

After:

Test fitting the crown mounts:

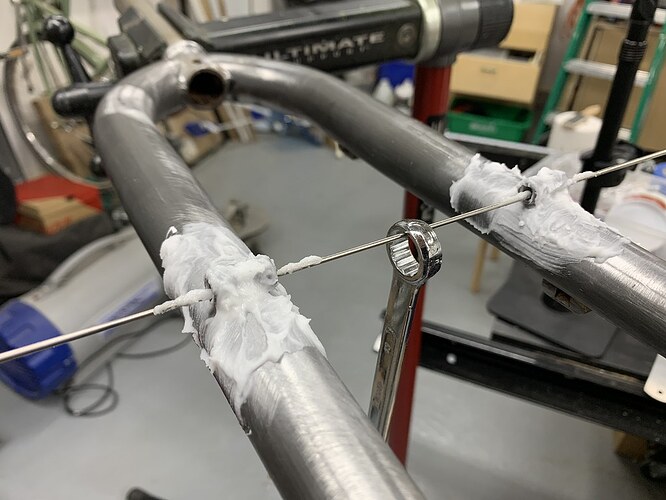

I took the suggestion from @terraformbicycles and used a spoke with a wrench in the middle to keep the bosses aligned and weighted down. And brazed them on with Stainless Light Flux, and System 48. Exhausted the flux in a couple areas where I wasn’t putting filler on the top edges of the mounts, but I think I managed to keep the heat affected zone of the tube quite small and managed to get decent fillets on all of them.

Mocking up the placement:

All fluxed up:

Here is a video of the process in case you see anything I could be doing differently with respect to heat control, torch motions, flame size etc!

Post-braze:

Pre-soak:

Here they are after soaking the flux off without any clean up:

Close up, maybe a bit too much filler

Here it is with the rack mounted:

Great work. Happy my tip worked out for you. I originally saw it from a Repost on Cobra Frames Instagram.

If you want to save some flux, make it a little bit more watery so it is thinner and then apply. You’ve applied a lot of flux, which is great, but after a while becomes expensive. I find that too much flux makes it hard to see what I’m doing. Having it more liquid-y allows me to put less material because I can see what I’m doing.

If you’re using propane, I usually run 4psi in Oxygen and Propane for bosses like that. From the looks of your flux you did a great job on heat control and didn’t heat the tube up too much.

Thank you. 4psi on the oxygen and about 5 on the propane was what I was working with. I wasn’t sure if I should have used a slightly bigger tip for the larger braze on like this.

Thanks for the trip on the flux, I just didn’t want to run out but will go easy on it now. I was thinking back to one of the Paul Brodie videos where he jokingly remarks about framebuilders being sponsored by the flux companies because some use too much ![]() , while I was applying it.

, while I was applying it.

Funny that we almost have the same settings for pressures. I like to use small tips when working with silver on bosses. It is easier to concentrate heat into the boss when the flame is smaller. Always a neutral flame. I already do a ton of fillet braze clean up so I don’t like to do that on bosses. In general, I use the 2nd smallest Paige framebuilding tip for silver boss work.