Thanks! Yeah it looks like according to PMW website that the pocket accepts a square cut tube. The tube on my stem is maybe 1/32 shy of 1.125” which I think would be doable.

Paragon parts ordered! Going to cut a bunch of test tubes this week to fire up the torch and practice brazing back to back! I’ve got the torch setup, brazing rods and flux…seems like no excuse to just go for it ![]()

Now for the fun little things like trying to easy way to mark center of the stem, and keep the clamp in phase with the tube.

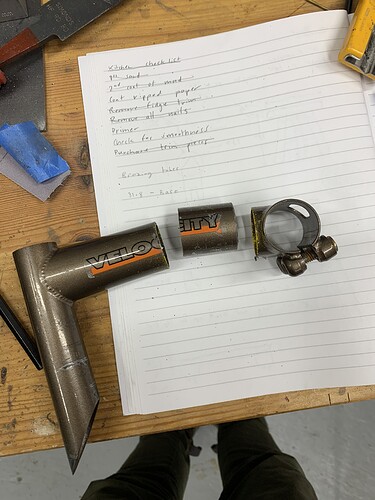

I wanted to get some extra rise out of my bars so instead of getting riser bars I took the path of most resistance and machined this.

It’s twice as heavy as a normal stem but I’m still very proud of how it turned out. I still need to round out the edges and maybe polish it up.

That’s rad! I Love top load stems, nicely done.

Manually machined? How much rise does it have?

Thanks! Yeah I don’t really see any top load stems for mtb. Maybe for weight reasons? And yes, manually machined. 20mm rise, and 50mm reach.

So fucken sick!

The path of most resistance ![]()

![]() This is way cool, very well done!

This is way cool, very well done!

Thanks for all of the tips on here and encouragement. Finally got comfortable enough to at least attempt this.

I sweat out a brass ring from the inside out and then built up a small fillet on the outside. A little lumpy. Did a bit of sanding and filing but don’t want to overdo it for my first time.

That’s a nice way to shortcut a custom stem!

It might be the lighting or angle in the photo, but a portion of that fillet looks like it needs more bronze.

I was literally just wondering that. I have a confidence I have a good internal fillet and was wondering if it’s worth introducing another heat cycle to try to add more. What would you do.

If you have some silver alloy (35-45%) you can make a fillet with it and then fill any depressions or voids in other areas.

I have some cycle designs system 48 which builds up pretty good that I could use if the silver content isn’t too high?

That’ll do just fine.

All finished! Hopefully maintained some of the spirit of the original one (got some smaller matching decals) and expanded the range of bars I can use. Let’s hope it holds up ![]() .

.

Riders use mullet to describe different combinations of components, this is the first mullet stem I’ve seen! Nice work, BTW.

Thanks! Totally going to use mullet to describe it now!

I want to build a zero reach integrated bar/stem for a kids strider project.

I thought Nova sold quill stock but cannot find mention of it in the old forums.

I am thinking 7/8 (.875”)x.065 is what the quill stock would have been.

Any thoughts for best practices on quill sizing?

Those match the dimensions I have used in making quill stems. If you plan on plating or painting the finished product its good to turn the o.d. of the quill tube down to roughly 22mm otherwise you’re going to have a hell of a time sliding the stem into the steerer tube.

Some shots of my first stem. Had some scraps from an Aircraft Spruce Bag o’ Steel that was in all the right ID’s for an 1 1/18" steerer, 1" bar clamp 80mm 0degree stem with 80mm stack. All miters done by hand, no fixture used, just a tonne of time dialing everything in & an intentional decision to make things easier by using 0degree cuts. The “lug” is actually a piece of sheet metal that I cut to shape & formed to the right diameter in a tube block then silver brazed it on post fillet brazing. It took a hell of a lot longer to get that thing shaped & bent to fit properly than I thought it would, probably will just do a proper bi-lam next time. I think it’ll look nice on the lugged rando frame it’s going on.