@crowe-molybdenum thanks for doing all the digging. Aside from the TINY bearing, it is honestly not the worst idea:

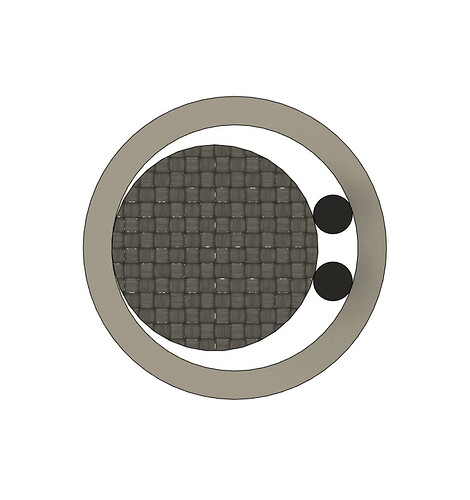

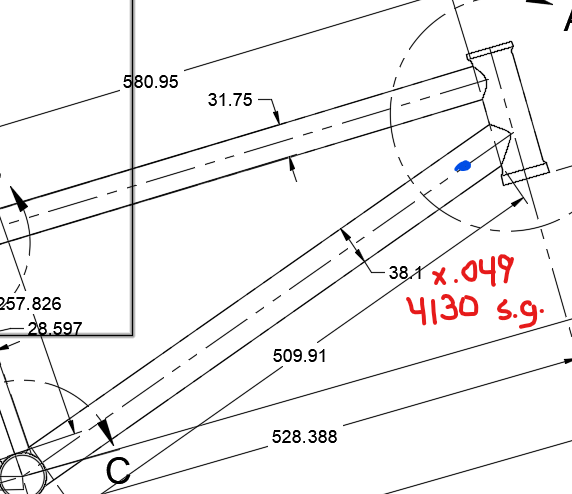

- 42mm OD 34.1mm ID bearing

- 5.4mm brake

- 1.125in (29.8mm) steerer

There is just enough room to fit two brake cables:

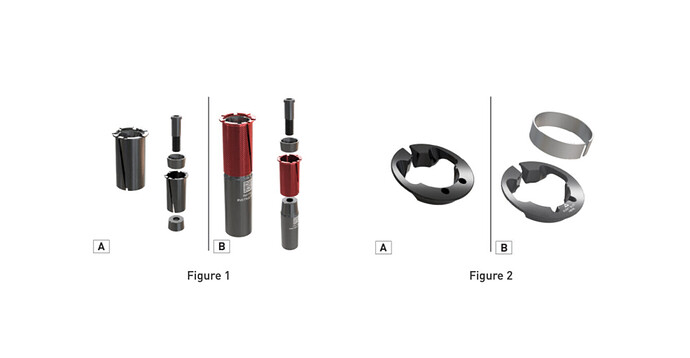

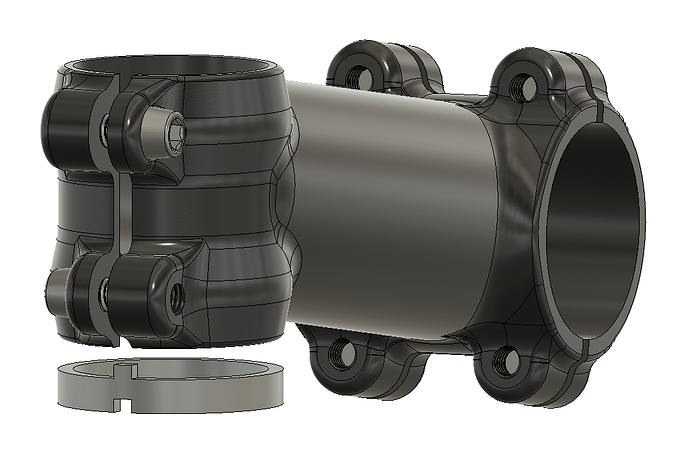

However looking at their wedge, it looks D shaped and eccentric:

Those sharp corners make me a bit nervous, that was the whole reason why specialized had to recall their SL7:

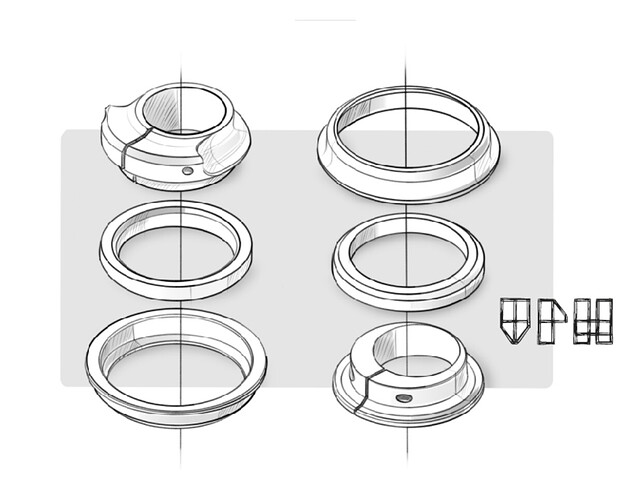

The first revised part is a considerably lengthened aluminium expander wedge that now runs from the top of the steerer tube all the way to below the height of the top headset bearing. […]. The second part (Figure 2, B) replaces the culprit of the issue, the metal compression ring itself. The new version is now two pieces, with a stainless steel sleeve sitting between the compression ring and the carbon steerer tube.

Well, we can only hope that these designs were lab-tested and tested in the real world. The strada system could turn out to be a good option for metal bikes. So far the Columbus fork is the only player in the small-upper-bearing-market: Futura Trefoil Road Fork – Columbus