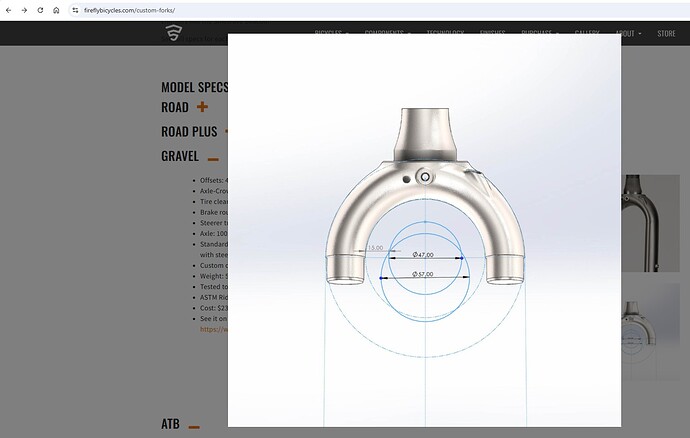

Firefly bicycles has a 3D printed titanium fork crown for tapered steerer tubes(the taper is incorporated in the crown in this design). This design or something similar could be investment cast in 4130 steel.

I would like a 1.5 tapered crown available in steel

BUT

look at the weird stuff I build; for example my recent track bike thread, road bikes with 2" straight gauge downtubes, mountain bike frames with 7 tubes in the front triangle… I think the thing here may be that there isn’t no place for it (wether or not its rational etc is a different story) , but the people who may want it are peculiar people, who have very specific ideas about they want; I imagine it would be a nightmare trying to pin down a single design that would work for even three of those people, let alone 3-400 pieces worth…

for example, I would want it to be super low stack, work with blades at least 40mm deep, and have clearance for road 35’s only. otherwise, I feel, it would look super weird.

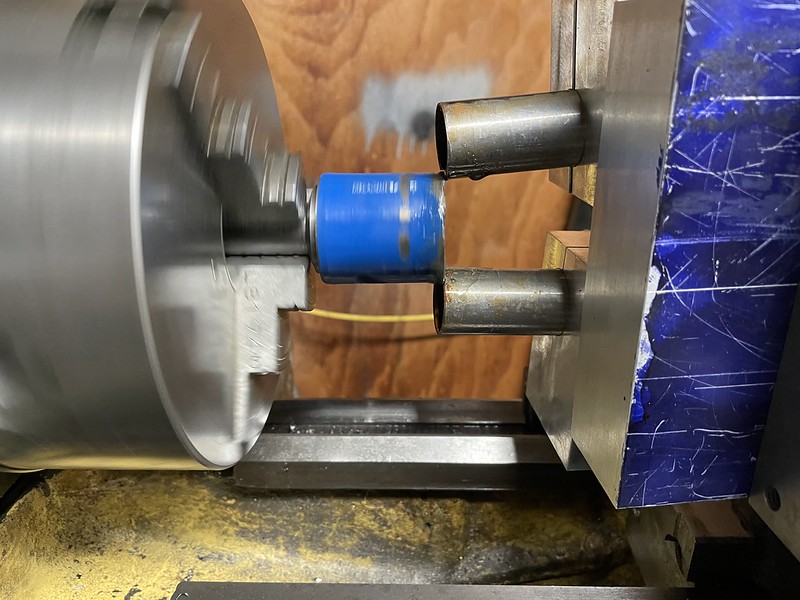

I have often thought one would make sense to the point where I made my own from existing crowns. These all ended up being pretty heavy:

Always wondered how these type of forks are made.

Are the legs mitered at all? Or they just touch and filled with brass?

Thanks

I made a cargo fork with a tapered steerer to fit an existing frame

I built a fork like this (28.6 steerer though) under Alex and Andrēs at ETB. The blades just touch and the fillet does all the work.

I did say it was my opinion. ![]() I would never build a bike to take a multitude of forks. That actually doesn’t make sense to me. I get the desire to have one bike to do it all but they are always a compromise in my mind. A frame and fork go together and are so intrinsic to how the bike rides as a package. I guess its just my mindset and I wouldn’t ever do the steel tapered steerer.

I would never build a bike to take a multitude of forks. That actually doesn’t make sense to me. I get the desire to have one bike to do it all but they are always a compromise in my mind. A frame and fork go together and are so intrinsic to how the bike rides as a package. I guess its just my mindset and I wouldn’t ever do the steel tapered steerer.

Some clients want a custom fork to replace an original production fork. In cases where the frame is designed for a tapered steerer tube fork, they have no choice but to use a tapered steerer tube on the replacement fork.

there are conversion headsets with a bigger bottom bearing to run 9/8" steerer tube forks in tapered frames

There are headsets that will reduce a 1.5 to a 1.25. That would be a better solution than a tapered steerer I would think.

A 1.125"-1.5" steel steerer weighs only 67 grams more than a 1.125" steel steerer of similar wall thickness. It’s more practical to retain the original headset and use a 1.125"-1.5" steerer.

i guess so but if someone’s just looking to replace a fork on a bike they already have it would probably be more practical to buy one off the shelf with the correct atc and rake and use an adapter headset than commision a custom fork. it would certainly be much less expensive. either way they do have a choice, which was why i was responding.

i’m not arguing against tapered steel forks btw, i just don’t really see a practical use for them. doesn’t mean they shouldn’t exist tho!

@incepi it might be worth bouncing your idea off Alex Meade. You may already be aware that he produced and sells a lower lug for tapered head tubes. The product page does state that the reason he developed the lug is so builders could accommodate the many tapered carbon forks on the market, but he may have some interest in the idea of a cast crown too. If a head tube exists and a lower lug to fit it, why not a matching fork crown too?

I would buy and use a crown like this, as would a few others, but it sounds like many would not. Judging by the skepticism here of any objective need for such an item and the reports of how expensive it would be to produce, it seems like the original question has been answered: the why. Now the question becomes: Is anybody out there actually interested in taking this on? If not, I say use 3D printing. It’s the perfect technology for low-demand parts that are not easily made by machining.

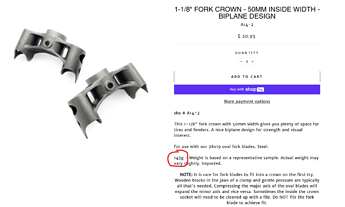

3D printing is not the ideal technology for fork crowns due to cost. For a builder it is an acceptable cost(since they are purchasing directly from the manufacturer), but for a distributor it is not. There is no margin. A 3D printed crown(of conventional design) in stainless steel costs approximately $150. The resale price would be over $300.

An investment cast fork crown can be made for about 1/10 the cost of a 3D printed fork crown.

Here is some quick armchair math:

Cast fork crowns weigh~150g

Cost of stainless printing ~$1/g > $150 for a printed fork crown.

If someone wanted to make a tapered steerer cast fork crown, all they would need is:

- 3D CAD model

- An email to Allotec

- ~$5000

Here is an email from 2022:

Hi Daniel,

Please provide 2D/3D drawing for us to estimate.

Typically, casting tolerances are usually +/- 0.2 or unilateral 0.3, and anything smaller than that will require CNC.

The mold fee of fork crown is about USD 2500.

The mold fee of dropout is about USD 3400.

The mold fee of lug is about USD 1100.

No minimum order required. The shipping fee is depending on the weight.

Richard has a great point, all the resources and information is out there for people, all it takes is commitment and money:

I’ve personally invested thousands of dollars into the EC37 project. But even though there are clear technical and financial advantages of EC37 does not mean it is commercially viable. Sometimes, you need to commit and see it through to the end.

The fork crown mold is expensive because of the hollow sections. It is not a simple one cavity mold. Inserts are required. The wax has to form unsupported thin sections in hollow crown designs which makes wax pattern manufacturing difficult.

A popular design could be economically viable. The issue is determining the geometry of that design. Perhaps a selection of three designs could be proposed, and framebuilders could provide feedback.

- An email to Allotec

I had questionable results when using Allotec for my parts. Warped, and warped some more. The tools were transferred to another foundry and saved.

There are other foundries that produce bicycle parts.

I’ve dealt with three.

If you ever decide to make the leap, contact me via email.

Conversion crown races are available if you want to switch between a steel fork and a tapered steer tube fork. The problem I see is that most steel fork blades look like crap when combined with a 44mm head tube. But maybe I could get used to it. I (mostly) got used to straight fork blades.