I have been admiring some of the wishbone seat stays that have been posted. I’m currently researching materials for a stainless steel frame to build. Instead of using xcr tubes for the seatstay, is there any reason to not try bending some 10mm 316 stainless tube. I understand heat from brazing it will weaken it to an extent. Will this be a problem or has this been successfully done before?

@IvanV Welcome!

There is definitely some mystique to stainless steel in frame building. I have a lot of questions about it too…

I am not a materials expert, but I can take a crack at this question:

316 Stainless has tensile strength around 600MPa. In comparison, 4130 bike tubing is roughly 900MPa, and fancy bike tubing like velospec and Reynolds 853 (which are basically identical) are ~1100-1200MPa.

All steels have similar stiffnesses (modulus of elasticity) of 200GPa

I know many people use 12.7x.09 (.5x.035in) 4130 seat stays with no problem. If you use that as a baseline, then I think you would want to use >12.7mm for stainless seatstays to maintain strength parity. That being said, a rider’s weight/riding style or a builder’s fabrication technique will probably contribute more to strength than the seatstay diameter.

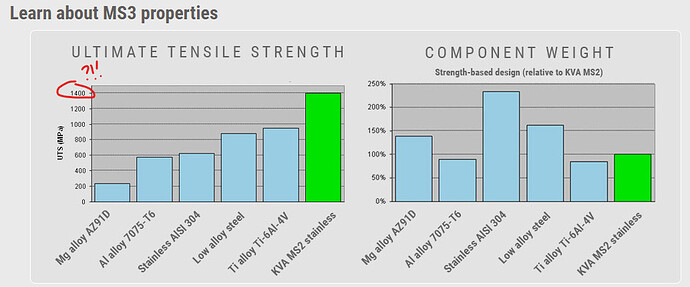

I am also curious how these bike tubing companies end up with these magical stainless alloys with amazing mechanical properties (1400MPa!):

@englishcycles is the skinny stainless SS expert, hopefully, he can chime in with his thoughts.

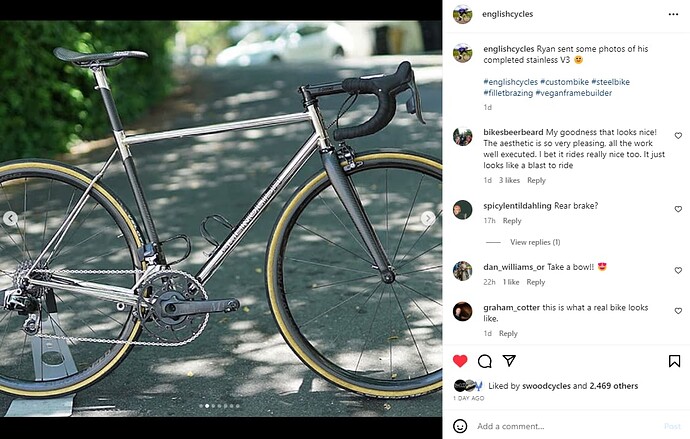

https://www.instagram.com/p/CuEJv_ROEIc/?utm_source=ig_web_copy_link&igshid=MzRlODBiNWFlZA==

It would be helpful if you provide a bit more information about the build:

- use case

- rider size/weight

- CS construction/dims

- intended brake method (disc vs rim)

e.g. a track bike for a 130lb rider is different than an all-road for a 160lb rider.

I tried the exact same thing with my last XCR gravelbike. Since I am using 10mm 4130 seatstays for my non stainless gravelframes I figured I should use 10mm 316 for the XCR frame. The 10x1mm 316 was so soft that it arrived not straight and I could bend it back my hand easily. Bought some 10x1.5 and 12x1 after that but these still didn’t feel as stiff as my usual 10mm 4130. So in the end decided to ditch the superthin stays for XCR bikes and just get the real deal.

I have been using the 12.7x0.9 4130 for my HT’s and fullies, and the 10x1.0 4130 for my gravelbikes, and so far both have worked without issue.

But to answer you question: Bad idea? Yes!

(Another advantage of XCR is that it is slighty magnetic, makes it easier to keep in place in the fixture ![]() )

)

Thanks for the responses. In terms of use, it’s for myself. I’m 83kg and it would be for a road bike, used for general road riding. I’d use disc brakes and was looking at 10mm 1.5 thick tube, but could increase in size.

I think the sensible route is to stick with known xcr tubing, but still like the idea taking this to a theoretical conclusion.

I am by no means an expert on materials, however, I will say that the seat stays are really an area that you can go quite light in because unlike other tubes on a bike they really only see compressive loads which steel tubes of any size are quite capable of handling. Personally, I use 3/8" .028 wall (roughly 10mm x .07) on my own bikes, rim and disc brake, without issue. I use standard 4130 and 304 stainless. I believe 316 stainless is a little harder to machine(cut/file) than 304 but the UTS should be the same. Lastly, since this is for yourself, if it doesn’t work out seatstays are the easiest tube to replace should you not like the result and a failure at this joint will likely give you warning signs before it fails like creaks and a failure isn’t likely to result in a serious accident.

I have made the mistake myself before of confusing stiffness and strength. A tube that is easier to bend does not necessarily have a lower stiffness, just a lower yield strength. When I bend 316 stainless tubes it is so much easier than 4130, but is equally structural as part of the frame (likely there is some work hardening from the bending that increases the strength a little in that area).

All the stainless frames I have built (all brazed with Fillet Pro) use 316 for the seatstays. Diameters are 8, 9.5 or 11mm depending on the application, with wall thickness from 0.5mm to 0.9mm. Test bikes for myself have used 9.5 x 0.5 and 8.0 x 0.7; both have performed just fine (I am 140lbs). I also use 316 for sleeves for ISP bikes and for custom stems.

Hope this helps!

thanks, Rob.

thanks all for the replies - this forum is a fantastic resource , I’m grateful for the help and suggestions. I think I’ll give bending some 316 tube a try - I’ll report back.