Nick and I had a chance to visit and tour the legendary Paragon Machine Works. I was there to pitch a couple of ideas, talk about 3D printing, and this forum. I left with a free titanium bottle opener, all ten fingers, and a lot of respect for what they have done. What impressed me the most was how such a small team and humble facility produces so many different pieces of our craft.

Mark and the team were excited about this new forum, so show them some love!

Despite what the shirt says, this is Mark Norstad, founder of Paragon Machine Works

Coco is on the front lines fielding questions and sending your goodies. Apparently, she gets a lot of questions about slider and hanger compatibility. Do her a big favor and make your sliders compliant with Paragon’s!

Everything happens in a relatively small building hidden in a residential neighborhood (not an exaggeration)!

Zip tie guides don’t make themselves

Hangers and fixture plate

Before: giant plate of steel

After: smaller plate of steel with holes

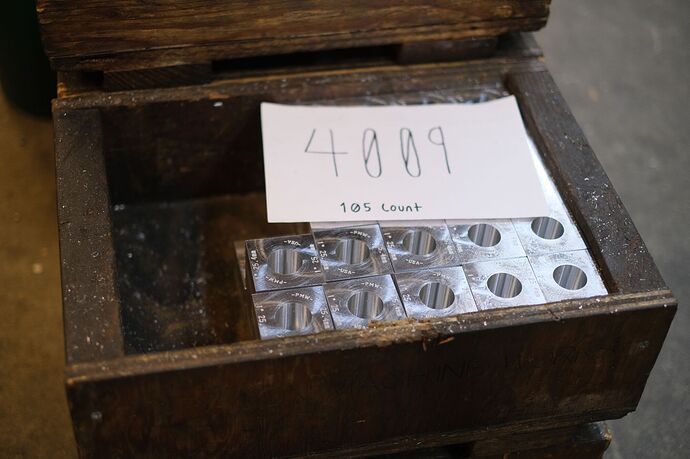

If you are waiting for the 1in tube blocks, they are here. Slot not included.

I hear dairy free yogurt is the best lubricant for framebuilding

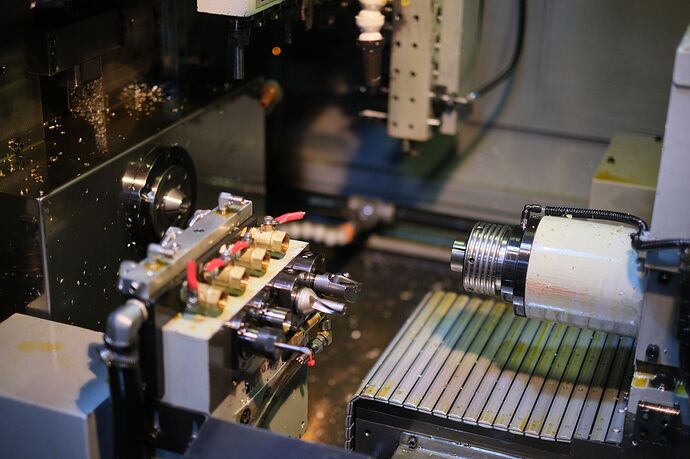

This CNC lathe is dedicated to turning the Paragon’s custom screws.

A framebuilder’s worst nightmare.

As a 3D printing guy, I have no idea what is going on here, but it looks impressive

This lathe can be fed several 12ft bars at once.

Just hanging out

Even the humble bottle boss needs to be made by someone

I had to do a double take on that 280mm 44mm headtube

Misc goodies

And finally, no shop is complete without a shop cat: Prince