Must be a day to ask PMW general frame building questions. Can we please start a thread of resources for ebike building? Where can I point the framebuilder for assistance? I’d like to point them here because everyone is very helpful and would probably have insight on best practices.

I am really interested in E bikes too. During covid times, it was IMPOSSIBLE to find a motor and battery kit due to supply chain issues. I wonder if things have calmed down since.

As far as I know, there are two main systems:

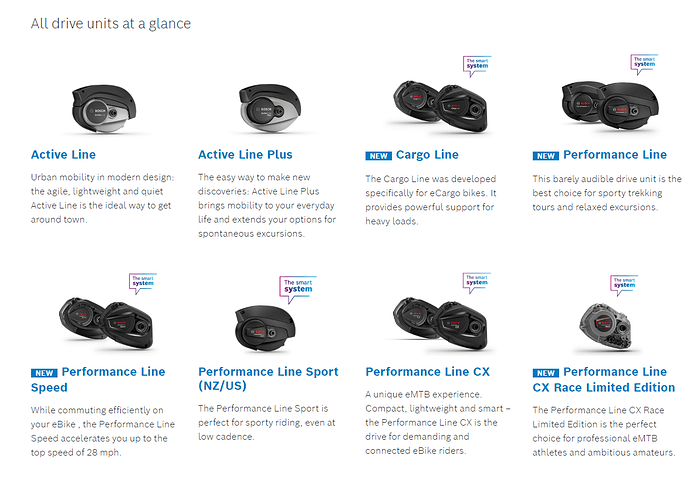

Bosch:

https://www.bosch-ebike.com/us/products/drive-units

Shimano Steps:

https://lifestylebike.shimano.com/us/products/e-bike/

The E bike space is a totally new area for me. The landscape is so confusing:

- different batteries

- different motors

- different mounting cabinets

- fancy naming schemes

It’s really hard to cut through all the fluff to get down to the technical details. From the custom builds I have seen, people have scavenged the motor and battery from an existing bike.

Some Inspiration:

Does anyone have any resources to get started? Has anyone built an E bike recently? Is there an emerging-defacto system for custom frames?

Last I checked, we were able to open an account with Bosch and Shimano ghosted us ![]()

I helped a friend build one a couple of years ago. If I remember correctly it was cast e steps and used a motor cabinet similar to this one from Framebuilder supply

Seems like multiple vendors sell the cast version, possibly supplied by ORA Engineering

Ticycles also has a sheet metal steel bracket and a helpful drawing on their site. When we made this frame we used the double dolphin fixture from Ticycles to hold it in his regular frame fixture

If needed I can dig through my files and find a step of the motor cabinet we used. There also appear to be some motor cabinet files on grabcad that may be helpful

I made an ebike with a motor from Kranked 2023 Hyperdrive Complete Kit – Kranked Bikes

And a battery from CYC https://www.cycmotor.com/b-series-battery-packs

Here are a couple photos of the bike.

I don’t have any personal experiences either, but saw this guy on Instagram: https://www.instagram.com/phil_vandelay/feed/?hl=de

He uses a Bafang Motor, Eggrider V2 display und 20ah 48V batterie

He also has pretty rad content on IG und Youtube about custom cargobikes and machining.

The cabinet question confuses me. Is there a universal pattern?

The cabinets available to builders have not changed for the last 5 years, but I feel like motor companies have evolved their design. I don’t think Bosch uses the same cabinet for every motor they make.

Sorry I’m confused on what you’re asking. We used shimano steps e6100 for that frame iirc. It’s the only one I have experience designing and building with. Not sure about compatibility across different models and manufacturers, but the motor cabinet suppliers do note what models each cabinet work with.

That was basically my question, the motor compatibility. I guess shimano is pretty straightforward:

Motor cabinet for the Shimano E6100, E7000, and E8000 series STEPS systems. This mount also works for the Urban version of the E5000. It does NOT work for the Trekking version. Steel.

The Bosch system is more confusing. The cabinet says “Motor cabinet for the Bosch Gen 4 motor system. Steel.”

On the Bosh site, I couldn’t figure out which motors are “gen 4”. The motors look visibly different:

Bafang also makes some pretty cool mid-drive motors: BAFANG | M-Series

But I am guessing they use a totally different mounting system…

Oh gosh yeah the Bosch stuff seems confusing. I’m not familiar enough with anything but the one steps motor that we used.

It seems like ORA makes Bosch gen 4 and Bosch gen 2 cabinets as well as a shimano e8000 cabinet and a pinion drive cabinet.

is e6000 still part of shimano’s product line?

Also looks like allotec makes a pile of different cabinets

I’m learning that I need a lot more education in this e bike field regarding what’s available, what’s obsolete and what products are actually available for the small frame builder.

I recently put a custom cnc machined adapter plate for the previous version of the Shimano motor into a 24" BMX frame for a local electric skateboard brand as a prototype. That adapter plate was a massive boat anchor. (I’ll see if I can find the photos)

I started recently on building an ebike version of my Jester Enudro platform. Have the adapter plate bent up and ready to start barzing tabs too etc. and realised it’s a bike a really didn’t want to build. So I’ve shelved it. I was getting great hellp from Shimano with a written off EP8 motor and internal battery casing to use for fitment checks and promise of at least one complete setup for complete the prototype but it was taking time away from finishing off the other bikes I had started.

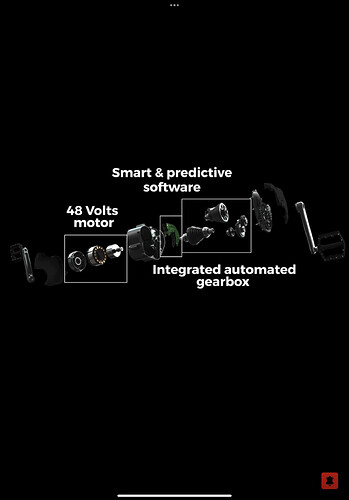

That being I am thinking of moving over to the TQ HPR-50 motor that Trek uses. Way more compact and easier to package with steel tubes.

The TQ system actually has me the most excited out of all drive systems. I just assumed they won’t want to play small ball with frame builders.

Harmonic drives are used all over robotics because they are high-torque lightweight actuators, exactly what a bike needs.

After having an EP8 motor and battery case in hand I just feel for what I wanted to do the packaging is problematic. Given the weight of a steel ebike over a carbon structure I wanted to use the biggest battery and go full power. Since stopping I’ve had some ideas to package it better but I’ll still wait till my XC prototype is built and running. In teh meantime I am going to contact TQ and see if they are willing to work with a small builder. I feel with it’s tech and the materials we use it’s a better choice.

I distribute Omnium Cargo bikes in Australia. All our frames are steel which is fairly unique among cargo brands and we offer an electric version with the EP8 motor. I agree that it’s a fairly bulky unit but it works ok within the overall design parameters of these particular frames. Keep in mind that these are cargo bikes with a 50mm ‘downtube’.

If there’s any info you want on this setup let me know. I’d love to do a bit of learning in this space too. And I’ll have one on display at the HBSA in June if you’re making the trip down. You’re more than welcome to have a close up look then!

I have designed a few E-Bikes with Bosch and E-Rohloff or a rear hub engine combined with the Pinion gearbox. This low entry 650b I delivered sometimes last year.

That TQ looks interesting. I do want to build a ebike commuter so I am not as sweaty when I get to work.

I built one e-bike and we have 3 more (all cargo bikes) at home. Hub motors are an often overlooked option that can be lighter, provide better ride quality, and are easier to incorporate into the bike. They have a bad reputation because people mostly seem them on the cheapest e-bikes, but the good ones are paired with torque sensing bottom brackets and provide a good ride experience. They don’t accelerate drivetrain wear like bb motors either.

I like working with Grin Tech in Canada, they are very friendly to small builders and DIY and have a wide range of motor options.

My most recent e-bike is Bosch based and I love the bike but dislike the Bosch system. The ride feel when you are riding at or above the speed limiter is terrible, the motor turns off very suddenly. It does the same at high rpm pedaling (over 120rpm), which is really disconcerting if you are sprinting away from a traffic light. The Q-factor is unnecessarily wide and the system doesn’t allow for end user maintenance or configuration.

Hub motors are also the easiest systems to upgrade or replace as needs change. Our current path with proprietary mid-drive motor mounts and batteries seems like it is going to result in a lot of discarded bikes where the base of the bike is still in good shape, but the electric system is end of life’d and with a motor that can’t be serviced or replaced.

On Grin’s systems I like the G311 motor for light assist. It’s easy to build up a sub-35lb bike with this motor that has good range for commuting and utility use. On cargo bikes I like the GMAC, which is a very powerful high torque motor. For even lighter bikes I’m playing with a G370 motor, which is a scaled down version of the G311 that is the size of a dynohub and about 1kg weight, but still capable of sustained 300W assist.

The downside of Grin’s stuff is that their handlebar computer (the Cycle Analyst) is bulky and ugly. I’ve been hearing rumors of a replacement for years, but haven’t seen it yet.

Mahle also has a high end hub-based system designed for road/gravel bikes that looks great: E-bike drive systems - MAHLE Group

3.2kg system weight including battery.

Those are some really good points. I will research the hub motors more when I get some time. I totally agree that the solutions the industry adopts are not always the best for the framebuilders.

There is a lot going on outside of the traditional bike industry ebike world. Some links for DIY style motors and batteries.

A Valeo with a single speed and a belt could be interesting. Integrated automatic shifting gearbox?

Bafang has a lot of different options for motors and I think they are willing to work with smaller brands.

Grin Technologies makes some cool Torque and PAS sensors.

EM3ev is also a good resource for DIY ebike stuff.

Lightning Rods have been working on a new motor design with IPM magnets that can handle a lot higher rpm’s supposedly. Something to do with field weakening and a BAC controller? Looks interesting.

I am getting ready to build my first long-tail cargo bike, with a Grin supplied Bafang hub motor. I think the hub motor is ugly, but really functional, and when I think of the 15 mile commuting the bike is built for, I think it’s a great option for a heavier rider like myself, and cargo.