Hi All,

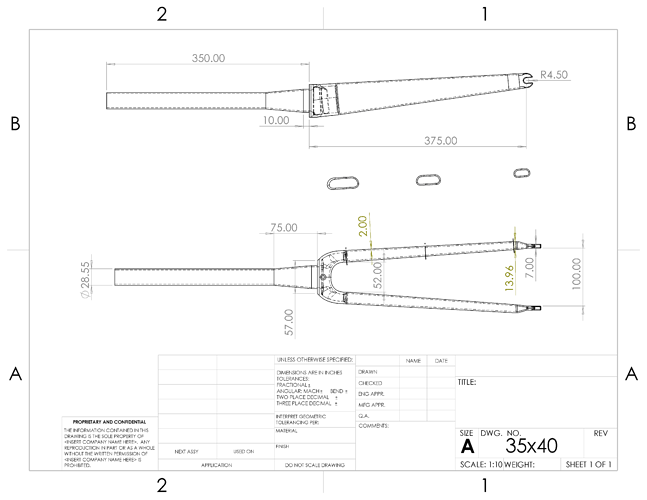

Just wanted to seek some advice on building an extremely tight fork. The intended purpose is for fixed gear street riding, so mud isn’t really an issue. The design requirements are:

- Rim brake (long reach – Tektro R559 long reach brake caliper – Retrogression)

- 40c tire clearance

- 375mm axle-crown length

Is this even possible? I’ve read conflicting things about 40c tire diameters when fully blown up. I know the industry standard is to give ±5mm to the tire to allow clearance, but if I wanted to do that it would result in a ~385mm A-C. I’ve attached my drawings below – let me know if this is possible and what you would advise!

The driving dimension here will be for the brake caliper not the tire, more specifically the brake mounting hole to the rim.

3 Likes

The axle to bottom of the fork measurement is 355mm (350mm (700c wheel/2) + 5mm (tire height))

What tire diameter are you using for a 40c? My 700x38 (actually measures 38) is 705mm in diameter.

I would have you double-check, but 4mm is the minimum allowable clearance. I typically aim for 6mm

Your project just reminded me of a problem we experienced with Colnago around 1999/2000.

A customer purchased a Colnago C40 Gold Edition. Super Duper Record, super tight clearances, etc. It was absolutely beautiful! Everything was great until he swapped out the tires/wheels. Suddenly there was tire rub.

I don’t remember the cost of the bike but I do remember the customer exclaiming, “For $____ I should be able to put whatever tire I want in there!”

Turned out that the problem wasn’t limited to that bike.

The applicable lesson: if you want tight clearances, measure the actual equipment before you make the thing and plan for variation.

Apologies if this comes off as pedantic. I’d start with that measurement, then actually measure your brakes, then design.

3 Likes

Don’t worry - I checked your drawing, dimensions are in inches so there’s tonnes of clearance

But seriously, measure the tyre and wheel combo you plan to use. Also the brake drop will play a big part. Assuming you’re using a 700c wheel, you’ll need roughly 311mm from axle to the bottom edge of the brake track (strictly speaking, to the tyre bead seat which is almost the same area, but measure your wheel to be sure), plus minimum 55mm from there to the brake mounting hole (using the R559). That’s 366mm, which gives you 9mm from the brake mounting hole to the crown race. So not mathematically impossible but doesn’t leave much wiggle-room. Measure the wheel/tyre combo and the brakes, line everything up in a fixture if you can.

2 Likes

I feel pretty confident you’ll need to add a few more A to C to get 40c clearance.

My Rasa Model is designed around the 375mm / 45mm rake Whisky Mid Reach Brake Fork that comfortably fits 38mm (measured) but not quite 40’s. It has the shortest possible crown and an axle to brake height of 362.49mm. Pictured below with 35mm Pasela

If you’re going for clearances that tight I would see if you can get the actual wheel, tire and brake the customer plans to use and build the fork with them. You’ll definitely need a lugged fork crown to get this tight of clearances. Straight blade crowns have too much rake built in so you’ll need to curve the legs on a zero offset crown.

If you’re building the frame too you can use a 44 or 34/44 headtube and use a zerostack headset to get 10mm less stack to the headset and tighten things up

2 Likes