Yes there are foams like rohacell that can handle those kinds of pressues and temperatures.

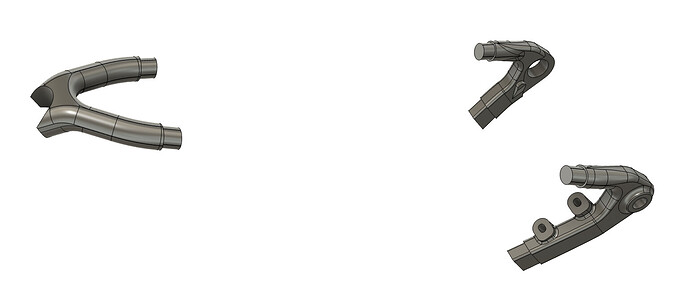

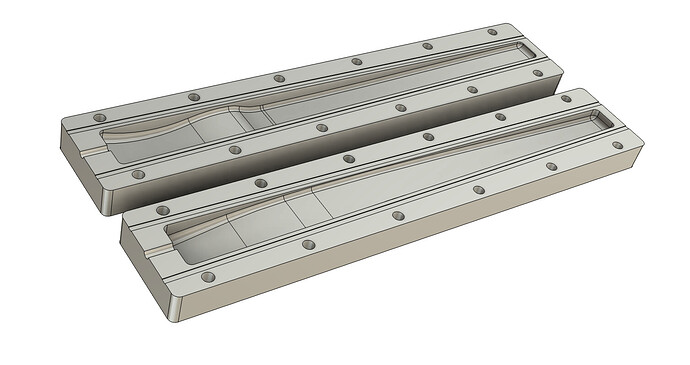

couldn’t spend much time in the workshop recently due to other responsibilites. So not much progress on my mountain bike. However - I did refine the cad files and designed some tooling for chain stays and all the compression molded parts of this future gravel thing:

Next week I’ll be back on the mtb build, but I’m excited to start machining moulds!

Looks very nice! I guess the design of the SS-ST thing allows a range of connection points to the ST? So that could have a junction where the TT and SS are at the same point on the ST?

My thinking was to start with this design as it is the easiest way to get some compliance into the frame, and to validate things it also makes sense as this is a worst case scenario structurally. And i like the looks of it.

Changing the angle of the seat stays can easily be done and only changes the 3d printed, somewhat sacrifial, tooling of the compression moulded parts.

I think forged CF is a great place to start even before joining tubes. I built my own CF front rack at home using DP420NS epoxy and AliExpress carbon tow. I wanted to make a lugged-carbon frame but just didn’t have the time to get around to it – this thread is a great inspiration to try again.

Any chance those dropout and chainstay moulds are open source? ![]()

Yes I will most likely publish the design files at some point.

Carbon rack! Inspiration!

Hi, may be interesting to see this seminar:

https://www.instagram.com/p/C2xUuFWOsoL/?utm_source=ig_web_copy_link

I already asked but unfortunately they won’t host it online. They might have a recording available afterwards, so everyone let them know you’d be interested in that

When I started I made a bunch of carbon bikes using tube-to-tube. I made all my own tubes too, and curing oven and had access to an ultrasound scanner to check the quality. It was a huge amount of work to go from something that looked bike shaped to something that was actually good. In the end it was taking about twice as long to make a carbon frame as a metal frame: Post Page

Here https://www.pinkbike.com/u/SleepingAwake/album/obviously-a-terrible-idea---diy-road-bike-frame/ under one of the pictures it says “the white part is the printed mandrel.”

How did you get that mandrel out of there again?

The mandrel in the chainstay was made from a soluble material and was washed out with a solvent.

The mandrel of the seatstays i just left in there.

Is it PVA?

Did you have problems with heat coming from the curing process impacting the mandrel before the curing was over? Did you take any special measurements to control that heat? Was it a standard PVA or some special one for making mandrels/molds for composite parts?

I used ABS, but I’m not necessarily advocating for that. Acetone can degrade the properties of the resin, i mitigated that by having a barrier between the printed core and the laminate and by making sure the resin was really well cured to get better chemical resistance.

I would probably look into HIPS which can be washed out with D-limonene, which is a much less aggressive solvent. Or PVA as you proposed. You have to do your own research, i have little experience with soluble cores.

If I’d have to do it again I’d machine the positive from a structural foam and leave it in. Not worth making such a mess to save a few grams. If you want it really light you need to make negative moulds anyway, to save yourself half the finishing steps. This is the route i went down for all bikes since, even though it was not for lightweighting purposes.

Thanks for the info!

I will be making some cf boxes that I’ll bolt to the bike so I’ll go with PVA probably.

depending on the geometry you can also just print in PLA and rip it appart when demoulding. or heat it up with a heat gun and give it a good yank with some pliers.

This has the advantage that you can print in PLA which is oftentimes a lot easier as it won’t warp as much and it is also stiffer than most other filaments. both of those things help greatly with dimensional accuracy.

Or as added complexity doesn’t cost you much with printed tooling, sometimes you can just make a multi-part tool that allows for demoulding even if you have undercuts.

If you can share your project I’m happy to give my input on how I’d do it.

I have a small carbon fiber box that I will bolt onto the head tube and a bigger carbon fiber box that I will bolt to the down tube. The latter box fills most of the space between the downtube and the front tire.

Things that are important to me: simple production process (see below), acceptable/good impact resistance and stiffness per weight, I would also be happy if the production process would be mostly environmentally friendly (no excessive waste).

I have not made carbon fiber parts before. So I would prefer a simple process. I can make molds in CAD relatively easily and then print them. Positive molds seem easier to me to make than negative molds although negative molds, I guess, will make for higher quality parts. This is just my guess.

My plan was to make a positive mold for the small box and a negative mold for the big box because the stiffness and dimensional accuracy for the bigger box are harder to achieve than for the smaller box.

For the positive mold I was planning to use PVA. I did quite a bit of research whether the PVA will warp due to the resin’s curing heat. My conclusion was that it is unlikely to warp significantly (with a slow curing resin) also because the resin layer is relatively thin. I can share the step by step process I came up with if anyone is interested.

I’m curious what your thoughts are and how you would approch this.

Regarding the PLA option for the positive mold you mentioned: I can’t imagine how it would be possible to break out a PLA mold from the relatively inaccessible inside of the box without destroying the box given that the mold also needs some strength.

Are you imagining a thin outer layer mold which is mostly held up by a support structure? In that case I can imagine being able to break it out.

Where to you buy carbon tubes in EU?

I’m thinking of making a carbon rear end for my bike.

Also it is quite hard to figure out the tube size I need. My rear was made with 22.2 and 19mm 0.9 wall Columbus tubes.

Great if you want to buy all kinds of other things besides the tubes for cf manufacuring too, also has great instruction videos: https://www.easycomposites.eu/

Big selection / lots of different sizes: https://www.carbonrohr.net/