Very cool technique! Thanks for showing it. That is pretty impressive how well it worked.

Did you preheat the headtube evenly all the way around? I’m no pro but I remember when I did my framebuilding course that was the most important part when getting things hot enough to braze.

Right! I was quite impressed

I thought I did but this might be an area for improvement. I started with a very thin root pass (is this the right term?) to get an internal fillet. It’s possible it wasnt pre heated enough for this. I think it was well heated before I started building up the full thickness of the fillet

I’ll try doing a more even pre heat next time and see how it compares

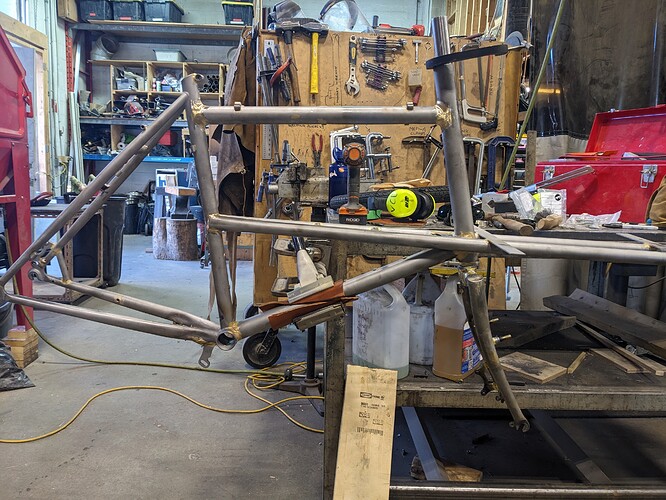

I’m slowly working away at the frame. I decided to use a gusset to help attach the cargo tubes.

I found this joint really challenging, maybe because it’s a lot of thick tubing, it was really hard to get things up to temperature so it took a long time.

The frame nearly done now and we’ve built a cute little segmented fork