I know that the answer is “it depends” but what is your experience on minimum required belt drive chainring clearance? I have now about 1,5 mm and I can dent the chainstay a bit more, but don’t want to if I don’t have to. Thanks.

Is it possible to add some spacers to the drive-side crank spindle to bump out the clearance? I recently dove a bit into this with Sean from White Industries. The outer bearing width (OBW) actually varies from manufacturer to manufacturer:

Internal T47 cups are 96.5mm on an 92mm shell because we couldn’t get to 96mm without making the flanges thinner, which we didn’t want to do. External cups are 11.5mm which gets you 96mm on a 73mm BB. Right above the T47 External cups specs is this for 24mm cranks: Shimano road BB cups are the same width as our cups. Shimano mountain BB cups are 1mm narrower than our cups so you may need to add a 1mm axle spacer on each side when using a Shimano mountain crank. So if you’re using a Shimano mountain crank or something with the same OBW specs, then you’ll need a 1mm spacer on each side.

Also, there is a variation in the actual BB width due to the facing tool.

For MTB’s I try to aim for 3mm of clearance to the chainring, but that is hard to measure and quantify. I think there could be an argument for more clearance, to allow the chain to fall down under the CS without being stuck, but you would need to sacrifice a lot of tire clearance to get that to work.

Well, spacers are not really an option as its a bsa square axle.

Already faced the bb to 68. Im not really afraid of chain falling of as it’s a belt drive. My only concern is rubbing.

I usually aim for 3mm as well, but this time I’m wondering as it’s my first belt drive.

Curious to see your results as well. I doubt the frame will flex more than 1mm in that location, and if it does, only for a fraction of a second.

I couldn’t find any documentation about chainring clearance: https://www.gatescarbondrive.com/~/media/files/gcd/gates-tech-manual-en.pdf?la=en

I chatted with the gates crew at Sea Otter. I am tired of lubing chains ![]()

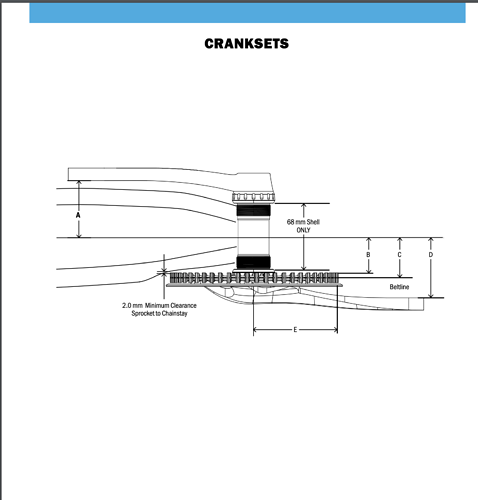

thanks for that document. I’m actually using continental’s belt and chainring so I did not look for gates manual. But this one you’ve linked clearly says 2mm:

I have 11mil from the center of the “centertrack” to the chainstay so let’s say probably around 6mm of total clearance

Depending on your centerline, I would say one option would be to use spacers between the “chainring” and the spider, I used to use brass washers commonly found on furniture for that task, super cheap, fit like a glove and they looked good as well.

Here is an unpopular take:

The chainring is made of plastic, if you rub it, you will notice it and most likely not destroy your chainstay in the process… The risk is minimal and 1.5 could be enough depending on how much is the flex.

OR

Smaller chainring?

I agree with this. I routinely build frames where the chainring barely clears and it’s never been a problem. The frame definitely flexes at the bb on my bikes (steel, bsa) but the whole cluster of tubes and parts are moving together so the chainring isn’t getting significantly closer to the stay under flex.