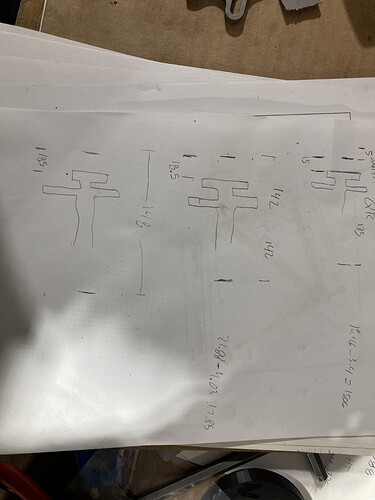

I am planning two single-speed builds (a dirt jumper and a single-speed MTB) which makes this topic timely. So far, I haven’t seen it discussed thoroughly, so I thought a dedicated thread would be warranted.

I’ve listed the options that I am aware of below with some notes and pros & cons if known. If I am missing something, any input is highly appreciated. Currently, my wish would be to use a thru-axle hub in the builds, 142mm or 148mm Boost, but it’s not set in stone yet.

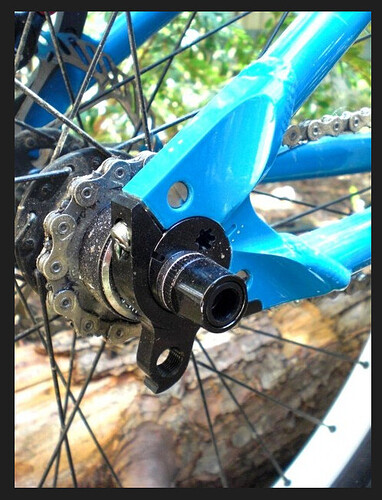

Horizontal dropouts

This is by far the most common one. It can work rather well but necessitates the use of 135mm bolt-on or threaded axle hub. When it comes to manufacturing, the ISO tab can cause some complications because of the varied axle position. I can see a situation in which the rear portion of the brake caliper would prevent the chain tension adjustment by hitting the rotor. Has anyone run into this issue?

BFS “Fish head” dropouts go around this problem with slotted ISO tabs. However, the CS and SS tube diameters

Slider dropouts

PMW slider dropouts are a tried and trusted product. I’ve had some slipping issues on one set, but I can live with them. A big plus is that the disc brake mount is handled in an exceptionally nice manner with this option. However, on the dirt jumper, I would like to go with something a bit simpler or even minimalistic in style.

Eccentric BB

It seems that eccentric BB’s aren’t used much nowadays. Some early models apparently had their share of issues: slipping, creaking etc. Bushnell bottom bracket seems to be one of the better ones. However, it does come with its own requirements when it comes to the BB shell.

One interesting option is the Trickstuff Exzentriker. A big plus is that it fits the standard BSA bottom bracket but is only compatible with Shimano 24mm HT2 cranks. Not a big downside, though. The reliability of the system is a question mark.

Eccentric dropouts

Related to EBB’s, eccentric fittings can be made on the dropout end of the frame. Starling Cycles has done this with their fantastic-looking Beady Little Eye frame. This solution requires some parts manufactured solely for this purpose. In addition to that, Some concerns do exists if the system can hold the rear axle in place and the chain tension constant if the axle is secured in place with one (or two) pinch bolts only.

Chain tensioner – Meybo-style

It’s simple, but it works. BMX race bike company Meybo has created a simple chain tensioner which consists of an adjustable arm and a simple slider part. One positive side is that it can be accommodated to any dropout somewhat easily with any axle standard, and the overall simplicity.

The downsides are the looks (at least to some) and that it’s prone to external damage. However, I’ve yet to see one damaged on a Meybo bike.

Moonmen – TI Tension System

When learning about this topic, I stumbled onto Ti Tension System used by Moonmen. Overall, I applaud the engineering and manufacturing that has gone into it! I thought it’s worth bringing up, if not done already.

As said previously, all input is highly appreciated.