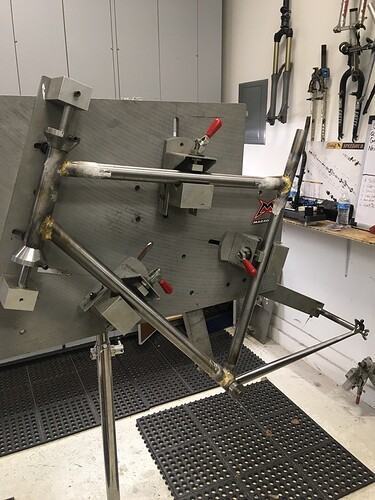

Digging through the archives for the pics of my first frame! This was circa 2018, I was 20 at the time. Frame was made at the first Susitna Bicycle Institute HQ, a separate 700ish sq ft garage next to the house me and my friends lived at. Made use of an old Nortac frame jig that was passed down to us from Jon Evingson, a retired local frame builder who was responsible for many of the first fat bikes.

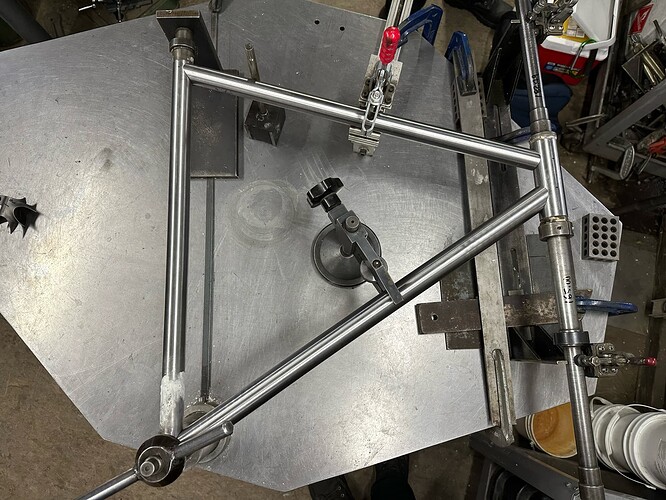

Here is the DT-HT miter. My friend Scott was showing me how to make a bike, and very wisely had me hand file everything. I didn’t use a miter template, or any specific sized files, or even a hacksaw to rough out the shape. Just filing with the round end, using a digital angle gauge, and checking the fit.

It was tedious, and the Nortac jig was difficult to use, but I was and am still so lucky to have access to these tools and skills.

Referencing the head tube angle to figure everything else out. Not pictured is the bikecad diagram, and the 1:1 size printout used to reference.

DT-HT joint. Not pictured is the ST-BB, which I brazed first. I remember spending lots of time in the puddle, smoothing out lumps, and adding lots of filler. The beginning of some trouble. I believe the HT was 1.1mm thick.

This is the BB end of the DT. I had fully fillet brazed the ST to the BB, so I had to really round off the ears of the compound miter to get it to fit right. I’m sure this made it more flexy, and I wouldn’t do it this way again.

More detail of the miter. Also a good shot of the rough jaws marring my tube blocks

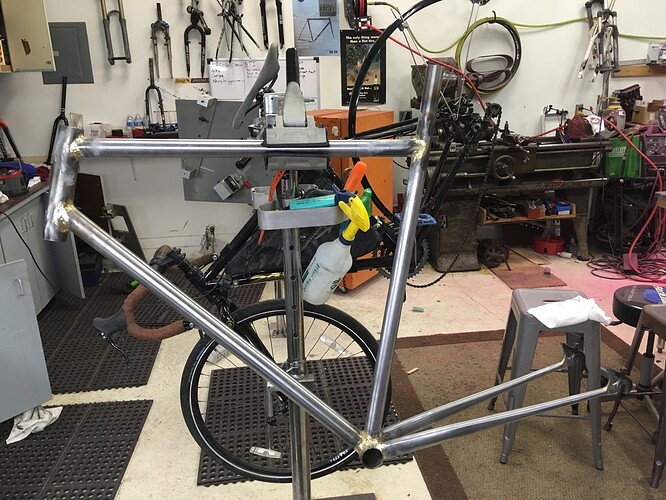

I brazed ST-BB, HT-DT, and then brazed those two tubes together. I’m not entirely sure, but I vaguely remember checking for twist once HT-DT-BB-ST were connected. Then mitered the TT to fit off of the top of the HT, and then kind of to wherever it fit on the seat tube.

Front triangle all mitered, with lots of extra seat tube

Then hacksawed and filed slots into the straight oval chainstays. Obviously really charred this up. Poor shimano dropouts.

DS stay mockup

Chainstays brazed on for sanity check, aligned them at this point. I remember struggling to get the chain stays the same fit/angle, which contributed to misalignment of the rear end.

Seat stays brazed on. I used some nice seatstay caps, and was very very generous with the filler at the ST juncture. I did have to file one of the dropouts to get the wheel to sit straight in the frame.

We had a homemade powdercoater and had done a few frames at this point. I was and am still very impressed with the quality of the paint job. Used a cutoff of some tange aero seatstay for the bridge. I miraculously clears a 40mm tire, but I didn’t add a braze on or make room for fenders unfortunately.

The bike got the Campy Record group and Ksyrium wheels off of my race bike, some stock carbon fork, and some fresh polished Paul Mini Moto brakes. Finished building it up in January 2019, and flew with it to San Diego for CABDA.

Built it up in the airport, and rode off.

I remember being so incredibly elated as I was riding it from the airport. I couldn’t believe that I made a bike, and it was riding straight. It was 60ish miles to where I was staying, and was an incredible ride. Seriously a trial by fire. I met up with my old college road racing team for their winter training camp, and had no problem keeping up.

This was an early oopsie, my friend gave me the adjustable reamer, told me to ream my seat tube, and left. I had no idea how it worked, and just went to town on the diameter it was set to. I really terribly thinned out the back wall of the ST where the binder bold was brazed, and it ended up snapping off in the driveway once I got back. Obviously my braze wasn’t very good either. Thankfully I was able to chop the other part off and use a regular seat clamp, which is still on it.

Pulled from insta stories

You can kind of see what went wrong in this picture. When I brazed the DT-HT joint, I really heated it up and warped the bottom of the HT quite a bit. With the thickness of the tube along with my first-time brazing skills, it didn’t stand a chance. It was super ovalized, and I hoped that reaming it out would set it right. Unfortunately it just thinned the back side of the HT out until it was paper thin. I was able to press the headset in, although it made a noticeable bulge and I had to hammer my fork in due to the misalignment.

I knew it was an issue though, and was able to keep tabs on it. It lasted all summer, and never catastrophically failed. I remember riding down some steep, offroad footpath to the beach and nearly endoing, hanging in a sketchy stoppie and saving myself. I figure that’s where things finally crumpled.

Also, it was cool to see the stresses in the frame and how they showed once the HT was cut.

Melted the tubes off

Sorry powdercoat

Did an ass job of rebrazing it. I went up a size in headtube, and ended up slacking the HT angle out to 71 from 72 I believe. 72 was a hair twitchy. I definitely rushed this process, and was scared of overheating the DT-HT joint again. I am super not proud of those joints, and was in such a hurry I didn’t even file them. Sigh. You live and learn I suppose.

This one got a rattlecan job

masked some chevrons

Redemption glamour shot on the aforementioned beach

Raced two seasons of cross on it since, and plenty of long rides too. Interestingly enough, the rear shifter teeth wore out, so that when I would really put power into the pedals, the derailleur would shift into harder gears. My standing theory is that the frame flexed enough (while I was riding mtb traisl) with the interrupted housing, that it put undue tension on the shifter and eventually wore down the steel ratchet. That’s why it makes an appearance as a Shimagnolo singlespeed here,

and as a dinglespeed abomination here so I didn’t have to race the lonely singlespeed category. The front derailleur cable slipped so I had to yank on it to keep it in the big dog as I crossed the finish.

I learned tons while making this frame, and over the past four years of riding it. I really wish I had done some cleanup on the repaired headtube, but I’m otherwise really proud of the build and subsequent repair. It’s still in regular rotation, and will be for a while!