I plan to use the DR1101 dropouts for the next build.

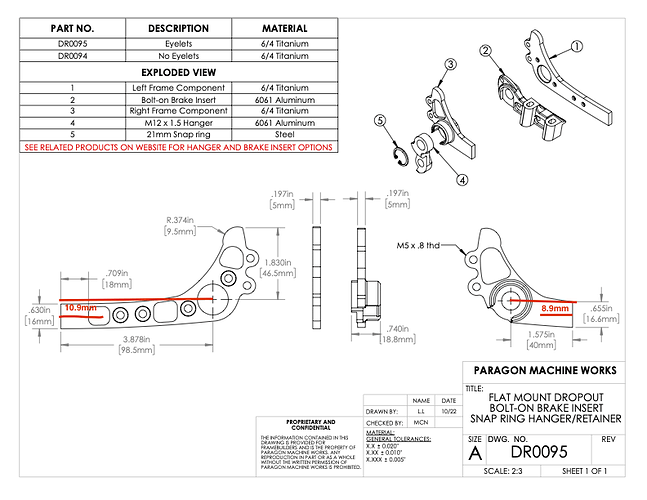

The centerline of the axle to the vertical center of the tab is offset. In this case the NDS offset is about 10.9mm and the DS offset is about 8.9mm (see red marks in above drawing).

If I were to slot the stays and attach them to the dropouts so the stays run perpendicular to the ends of the dropouts (the traditional method for tabbed dropouts), the stays would approach the BB shell at slightly different angles due to the 2mm offset difference between the dropout ends.

This offset difference causes the dropouts to be clocked at different angles, which affects seat stay length symmetry, d-hanger clocking, and axle slot clocking differences.

Is there a reason why the two dropouts don’t have the same vertical offset?

My first inclination for the build is to offset the DS chainstay at the BB by 2mm. That way I can still slot and attach the chainstays as normal. I think that would ensure that the dropouts are clocked the same.

What have other builders done to address this?