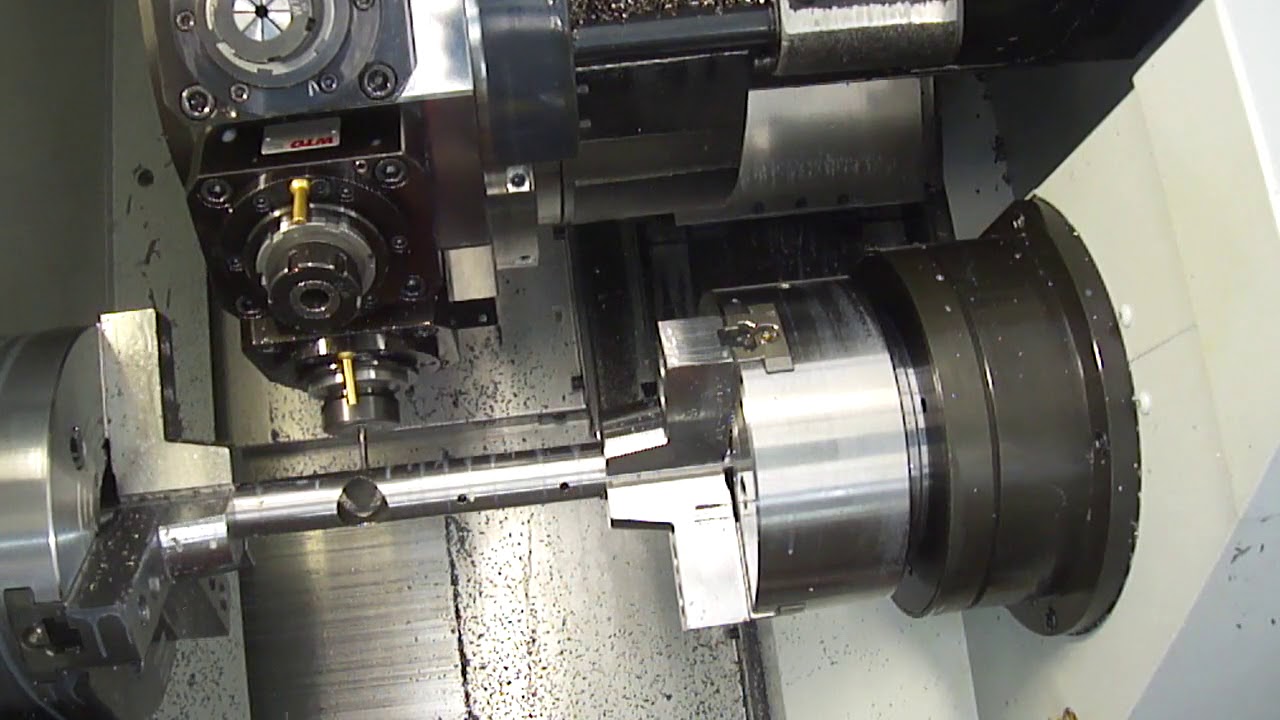

Oh that’s pretty cool. Co-motion has a cnc lathe that cuts their tubes like you are describing and after seeing the video of their machine in action I couldn’t stop thinking about an easier way to do it!

I looked at some of those laser engraving cylinder holders… But I think I may have to rotate the tube pretty quickly and forcefully to get up to the feedrate appropriate for thin walls.

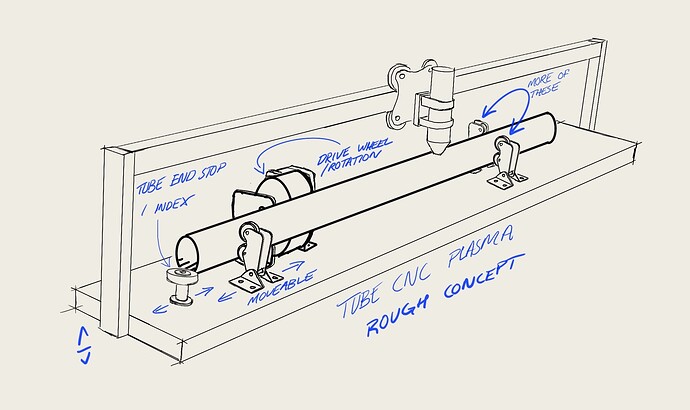

I just did a little sketch of a rough concept from my head. By clamping the tube between a series of rollers and drive wheels side to side, rather than resting with gravity, I think I’ll have the grip needed to rotate the tube accurately at speed. As well as leave a clear path for torch travel down the length of the tube.

My main concern here is the tube walking back and forth lengthwise as it rotates. I need a solution for that, the stop I drew becomes useless after that end is mitered…

Thousands of dollars of mechatronics hardware and knowledge, $1 sharpie at the end. I love it ![]()

Just enough technology for the project at hand!

That sounds like an interesting option… I’ll play around with it! I would like to cut bottle bosses as well as some other features (retractable lock cable) towards one end of a tube, maybe I don’t need cutting access down the entire length…

When researching frame fixture extrusions, I came across this website/community:

They have a whole bunch of open source CNC custom project examples. I thought this hotwire surfboard cutter was really cool:. Hotwire cnc Surfboards | OpenBuilds

They also sell pretty slick extrusion/actuator kits that they call “open rail”

I used to be an engineer for Strider bikes, our factory in China used a laser tube cutter and even robotic welding on the simplest joints: Head tube and chainstays. Generally 1.2 to 1.6mm thick straight gauge, results were pretty slick. It’s easy to buy the equipment when you’re producing 500,000 frames annually. The same factory produced a ton of different kids bikes and bikes for Pacific cycles.

I was also fascinated by the idea of laser-mitering tubes a time ago, and therefore I tried to find cases where a manufacturer was using CNC multi-axis laser cutting for that job.

I found this article about Helix and how they utilize CNC laser cutting.

The crazy thing about their products is that they also use CNC robotics for TIG welding the titanium bikes in an oxygen-free environment

Thanks @BS_Industries and @Frederiksoelver for the industry insight. I’m always surprised by the technology big companies have access to outside the fabricator world.

The journal name you linked cracked me up. We should rename the forum

The name of the laser is literally TheLASER ![]()

Not directly related, but I used a CNC plasma table for over ten years making all sorts of things. A perfectly cut edge from plasma cutting is extremely hard and a file will skate over it. This edge creates porosity in TIG welds if not removed completely. So you’re looking at abrasives to clean it up, and if it’s not set up perfectly the cleanup on thin sheet was always the biggest pain.

YMMV, but I’d play around with optimizing some flat, (preferably CNC for consistent feed rate) plasma cutting to a level you’re happy with before investing a ton of time around the rest of the setup.

that is effectively what bystronic sell to drop on their 2 axis lasers to stop it walking one end is the rotary with an expanding collet up the tube bore it also doubles as a bung for when they do titanium and gas it

Wondering with laser cutting if the heat interferes with the molecules of the material (4130 in this instance). When I have purchased 5mm dropouts that have been laser cut, there is scale where the part has been cut. If I were to laser notch a top or down tube, will that scale affect strength in the weld? Currently using a belt pipe notcher to mitre our tubes.

Welcome @ParadigmBMX !

I think there are two issues here:

- Scale

- Heat affected zone

The scale is contamination caused by oxidation and the oils and mill scale on the tube being burned by the laser. It can/should be removed with steel wire brushes in a drill and a sanding belt

For 4130, the heat-affected zone is actually a good thing, it strengthens and hardens the tube, which increases its yield strength. Obviously, too much of a good thing is not good, and too much heat will cause the material to be brittle.

The laser-cut tubes are done super fast, so anecdotally, they are exposed to much less heat than welding.

If you are in the US, I think the goto framebuild source for laser-cut tubes is Precision Tube Laser in Las Vegas, NV https://www.ptlmfg.com/. They are very professional and easy to work with in my experience.

Ivan made a great post on the effects of HAZ on bike-thick tubing here:

If I remember we correctly he used them to miter tubes but the more interesting use was making lattice tube structure that was plug welded inside the tube to support the shock mounting.

If I remember correctly this was due to the tube cutters only dealing in straight gauge so he can use a lighter tube with strong shock mounting.

Makes sense, and a cool idea. Those CNC tube lasers need a long continuous tube to feed the “Z-axis”. Butted tubes come in tube lengths already.

Back in the 1990s or early 2000s when Cannondale was building aluminum bikes, they were laser cutting their tubes. They left interlocking tabs & slots on the ends for easy locating. I think they offered a custom frame option as a result, stating that it was super easy to do as a result of this system. I found this old thread on Practical Machinist that mentions it. Manufacturing Resource | Aluminum Lazer tube cutting/mitering | Practical Machinist - Largest Manufacturing Technology Forum on the Web

It’s also mentioned on Page 5 of the 1994 Cannondale catalog. https://vintagecannondale.com/year/1994/1994.pdf

-Jim G

1994 the good old days