So I’m slowly getting back into CAD and wanted to work on some projects that have been floating around in my brain. It’s been 14 years since I worked with Autocad while I was going to school for metal fabrication and really enjoyed it. Well we only had access to the program until the next school year began and our student accounts ended. Since Autocad is normally out of reach of most people for the everyday Joe just using it for “personal” projects. I kind of fell out of using CAD. Fast forward to now where you can get a handful of good free CAD programs at a drop of a hat…Fusion 360, SketchUp, FreeCad…yada yada, etc.

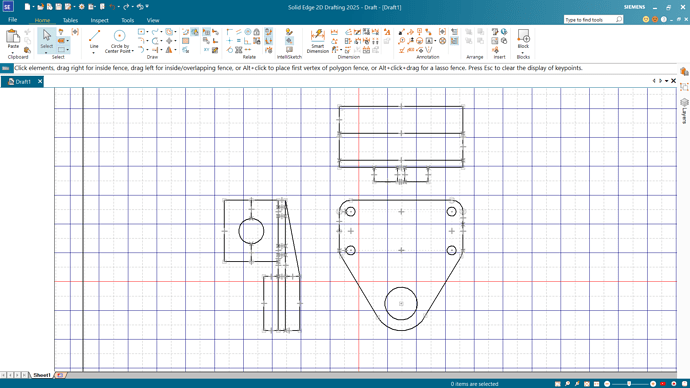

Downloaded Solid Edge because it reminded me of Autocad since I’m just using it for 2D designing. Tried Fusion but I still haven’t caught on to it yet but give it time and I will.

So I’ve got a thing for klunker type stuff but mixed with modern touches. So I’ve wanted to build a Cook Bros style bmx stem but for a threadless setup.

Someone designed a modern style stem under the Cook Bros name but never came fruitation as far as I know and it’s a little too modern and looks like every other modern BMX stem.

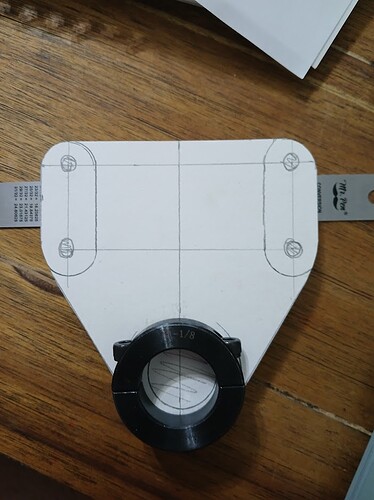

I just want a simple plate with moto style bar clamps and threadless. Now I designed the stem to be 70mm and use 7/8 clamps but luckily clamps can be easily swapped out to 31.8 and 35. I want very minimal machine work to make it easy and more affordable to build. So I designed it to use just a 3/16 steel plate or 7005 1/4 aluminum plate. The clamp portion will be two shaft collar clamps on each side of the plate either welded or brazed onto the plate.

Clamps

bar clamps

my plate design

Now question is about attaching the shaft clamps to the plate. I was just going to TIG the clamps to the plate. Just one half of each clamp since it’s a two piece clamp will be fused in one fashion or another. TIG would be easy and quick but could this be brazed on like lug to get full penetration underneath the clamp and plate? Where as the fillet TIG would just get the edges and leave the middle portion not fused? Or will either way be fine? I was going to have the clamp staggered with one clamp facing back and the other facing forward. I looked at stem clamp from PMW but for almost 60 that was a bit too much for this project. I could also use a piece of tubing and two binder braze ons. I just kind of dug the shaft clamp as it was also something you saw on high end BMX stuff back in the day…crank spindle clamps, axle clamps on sealed bearing hubs.

Whats your thoughts. Yeah it’s no weight wienie stem but that’s not my cup of tea. Though I think the aluminum version could easily be half the weigh of the steel version. They’ll also be two triangular braces that will be under the plate also for strength.