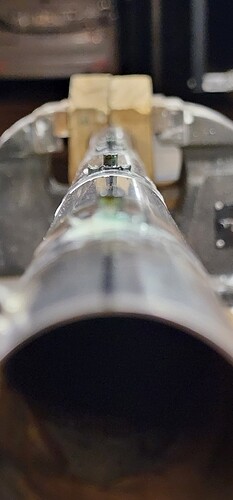

Your work is so nice! Your linkage pivot alignment is impressive.

What are you using for this braze on spring clip?

Thank you. Its just a bit of bronze rod as Im brazing with silver. I usually use old spokes for spring clips.

edit place holder

Metal 3D printed parts in the house! These could be cast if I was making a thousand of them, but when it’s only a few, 3D printing FTW!

A few cool features I hope will make things a hell of a lot easier to build and maintain the bikes.

Very cool! Your work is always excellent. Do you tap threads into the actual 3d printed part or do you use a secondary machined captive part?

I was tapping threads into the seat stay caps but everything is now two piece fastners so no threads to strip or damage in the frame.

@DEVLINCC Your seat stay plug has a super clean look. What a great system of parts!

wow, those parts are looking really nice! Great job!

Great work Sean!

Thanks guys. Pretty happy so far. So much work has gone into what I think works. Now its time to build with them to see what I got wrong! ![]()

Yeah that’s nice!!! It’s sweet to be able to experiment with different styles of braze-ons without having to get a mold made. I feel like we’re on the precipice of some real innovation in that space!

Absolutely! It definitely needs refinement and that is definitely not the fastnner intended to be used. lol. 3D sintered metal printing at that size is problematic though so need to delve into it some more. Have ideas on a no screw design as well which may mean a plastic top instead.

Now that’s interesting. I wonder how many others are doing that kind of internal reinforcement for cable/tubing holes.