Thought I’d jump in here and tell my story and then continue on with the build progress etc.

Bare with me. This may get long winded. ![]()

My back ground career is as a design draftsman, mostly mining and power gen. My first job out of school was in a mchine shop making parts for electron microscopes, off all things. I did that for a year, then a drafting course for a year and then a four year drafting apprenticeship. That first machinist job was in 1990.

I started riding when I was 14 with mates from school. Even did cycling as a school sport, which was unheard off in Australia at the time. Started racing almost straight away and won my second race in C grade against heaps of much older guys. Unfortunately wins were few and far bewteen as I didn’t have a good racing head and spent way too much energy early on. I am far better at it these days but alas the body has decided it wants to retire. ![]()

I have always wanted to build bikes but in Australia in the past it has been a very difficult field to get into with the plethora of framebuilders we had in Australia in the 80’s dwindling down to just a handful by the mid 90’s. Now though we have a strong, although still small scene, that has a great depth of talent and diversity with a few of the builders arguably among the best in the world at what they do. It certainly gives one something to aspire to in pursuit of this game.

Building bikes! After growing up and working mostly in Sydney. I found myself in Brisbane around 2006 and almost stumbling on the old email forum and then the Frameforum that Neil in England ran. I was able to delve into the knowledge base and started to pester Dazza at Llewellyn Custom eventually building my first lugged road frame mid 2014. This was quickly followed by a track frame, which I still haven’t built a fork for, lol.

Then life took a detour. Seperation, cancer diagnosis and job redundancy with in the space of 9 months left me reeling and in desperation put a call out build if anyone wanted a frame built so I could earn some money. Some would call it brave, fool hardy even with only two frames built but desperation can cloud the thinking at times. Fortunately I pulled it off with two orders and one frame built straight away, for a 6’8" dude!..and I was on my way.

Now in Australia selling custom bikes when you are a relative new comer is very hard. Working out how to market yourself, having space to build, figuring out where to get materials and supplies for a niche industry is hard and expensive. It’s taken a long time to establish myself. I’ve tried doing it as a side hustle, working in a bike shop as a mechanic for a few years. Then covid hit and I was out of work again so tried to do it full time. You’d think that would have been perfect timing but alas, the orders still only trickled in. I’m now back working part time as a draftsman and part time as a builder. The starving artist thing has a limited lifetime.

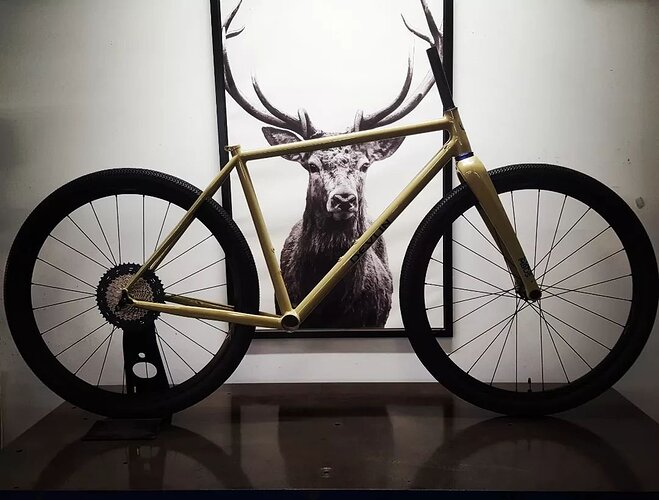

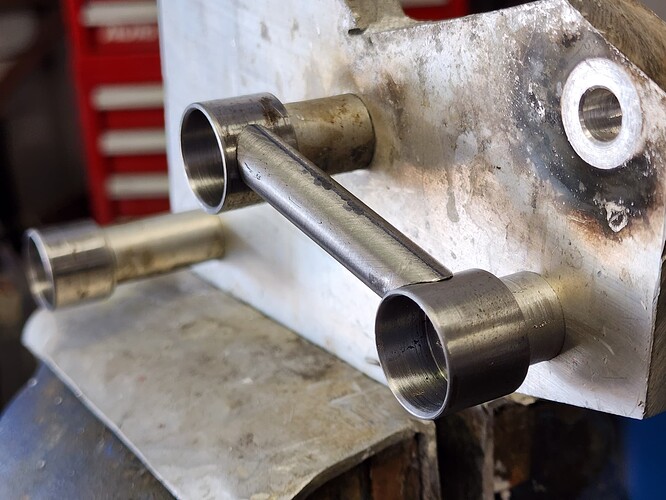

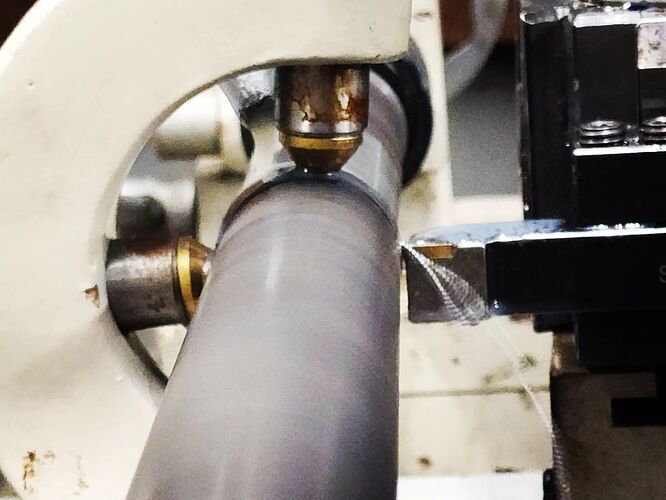

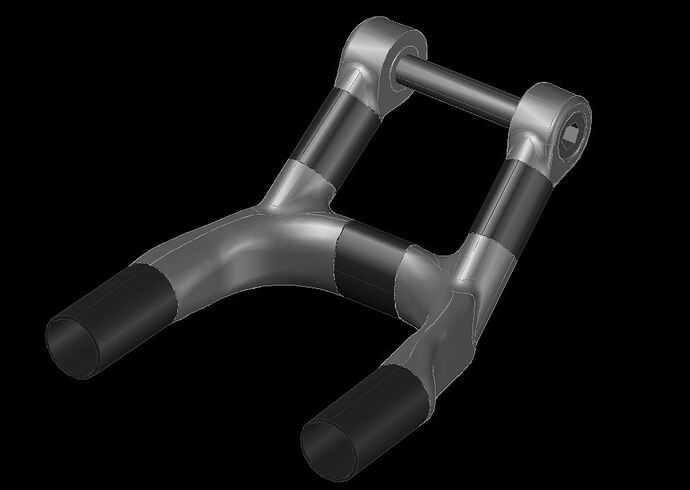

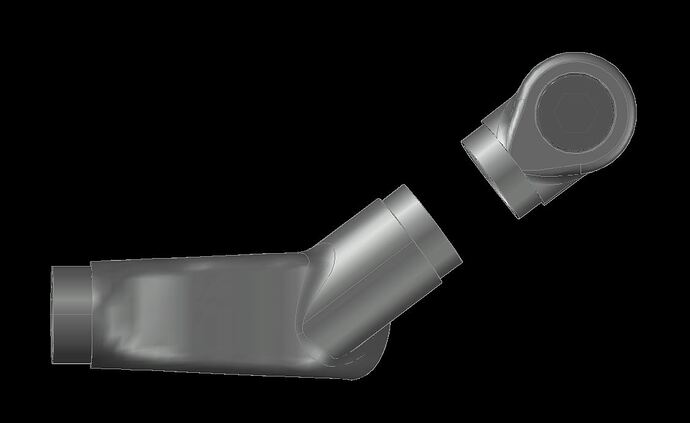

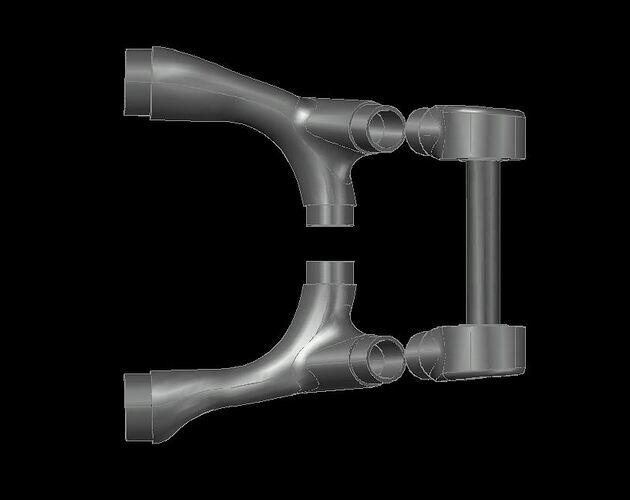

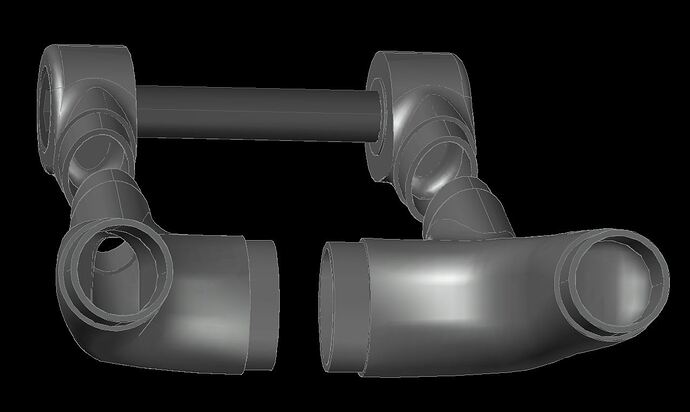

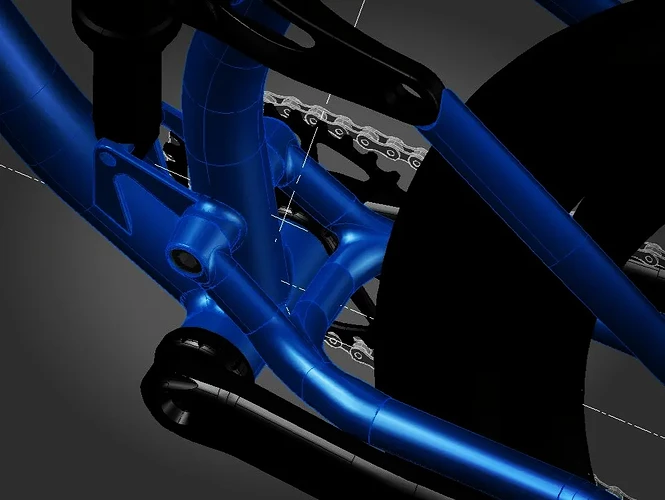

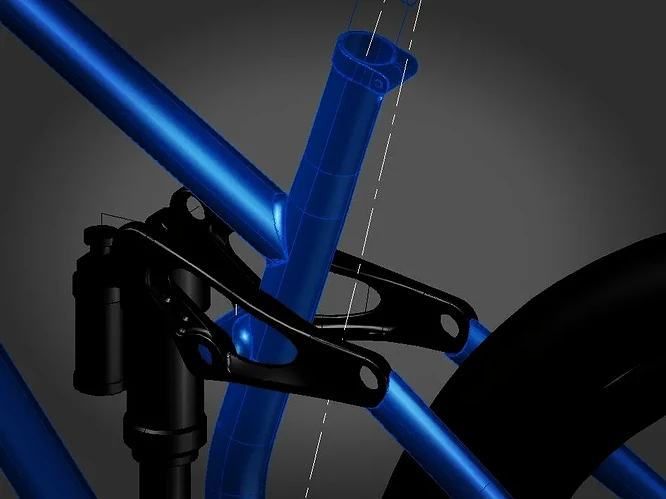

So far I’ve built nearly 30 frames. a good amount of them are road bikes with lugs only at first, through to bilam fillet brazing and now just straight FB with my signature frame carrying the loop bilam. I’ve done a couple gravel fames now and four full suspension frames, one a 140mm trail bike and three 170mm enduro race bikes.

I’ll put some photos up and come back later with some more on why I build the way I do now.