Hey all! Usually I’d try this out myself, but learning from other people’s mistakes is cheaper

I’m working through a design that uses 19.1mm chainstays. I’d love to keep cost & complexity down so the PMW DR2096 are pretty appealing. There’s not a ton of space to land 19.1mm chainstays on there, but it looks manageable with good fitup and heat control.

Does anyone have experience welding or brazing these? I’d love a gut check to see if this is a good idea or not. I’ve tried welding too-small dropouts before and don’t love the look of chewed-up edges. Fillet brazing is always an option, but I’d love to stick with TIG if possible.

3 Likes

I would totally mess that up. I usually ovalize mine to give myself wiggle room. Looking to see what better builder do.

3 Likes

I haven’t ever done that exact set up but I have done the narrow Paragon sliders with some pretty big stays that had a very similar landing. It can be done but you have to take roll off the pedal as you come around to the sides and you’ll want to adjust torch angle. I would suggest using a set of 19/16 chainstays from @BikeFabSupply to give yourself a little extra room.

2 Likes

I’m not seeing any 19/16 stays at BFS, are you thinking of BFD? I’m looking to hit a chainstay length of ~450mm so length is a bit of a worry

The DR2065 are only ~$16 more so that is another option.

1 Like

We’re about to run a batch of these, it’s easy for us to increase the width. What do builders want? 1" (25.4 mm) or wider? Let us know, we can do it!

8 Likes

@mark_pmw 1.04" on the DR2065 seems to be the sweet spot for 19mm stays imo!

2 Likes

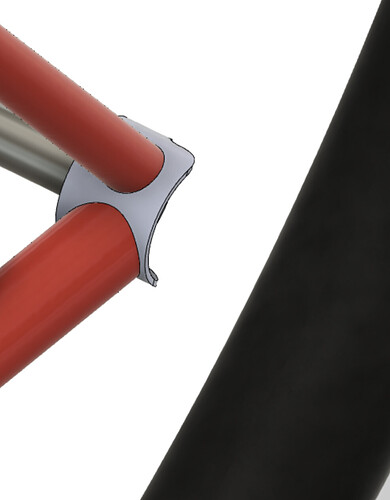

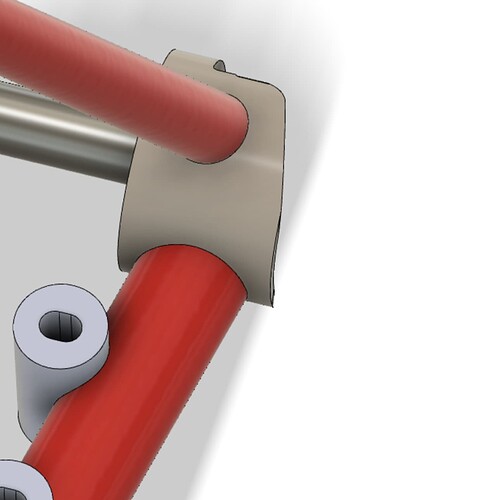

These also make great chainstays if you need a smaller dropout end.

3 Likes

Hit me up , I do have round 19mm x .9 , that tapers to 12 , but if you cut off at 450mm you would be around 14.5mm at the tip. The 19mm section would be 290mm so good room for bending sbend or single bend with a yoke. We also have our RD125 drops that are 1" wide x 1.25" OD as well if you need the width for straight 19mm.

I think giving a little squish in the vise or a press to the 19mm is just fine too though , squish them first them miter them, You will have a 17mm x 22mm oval likely but would not be much noticeable. Its all just fabrication , buy the parts to fit your needs or do a process to get what you need. do what you feel is correct , for both function and aesthetics.

Just my 2 cents

Andrew

5 Likes

OK, give us a couple weeks.

8 Likes

I’ve used lots of the DR2096s with 19mm stays. For brazing it’s no big deal. Still plenty of room to create a nice fillet.

I attempted to weld that combo and vaporized the thin edge of the dropout  . It’s not a combo for the faint of heart.

. It’s not a combo for the faint of heart.

I’ll cast a vote for @mark_pmw to make those dropouts with 1" flanges. It’s easy enough to grind away the excess post-weld.

6 Likes

Scallop the inside of your stay and cap, will give you a better shot.

1 Like

Hello! I’m thinking of using 19mm CS for my gravel bike too, but not sure if it’s more or less sensible than the usual 22.2mm for my application: all road bike, 435CS length for a 140-150lb rider who has sub-average power output.

May I ask for which scenarios did you guys think it’d be better to downsize in chainstay? Thanks!

Go with whichever makes your build easier. You won’t notice a difference.

4 Likes

Thanks Nick! I noticed a lot of folks using 19mm CS for MTB so it should be a problem. Plus, I have really tight gap for CS anyway so it wasnt gonna make sense with a bigger one…

![]()