Currently there is ‘standard’ dummy axle design that is essentially the legacy design created by Anvil Tools. Frame and fork fixtures designed for this system are unable to use other dummy axle designs. The narrow centre section of this design prevents other axles from being used in fixtures designed for them. Specifically, axles of a constant 3/4” diameter or 1.0” diameter are incompatible. I am proposing a reconsideration of this by fixture designers. If fixtures were designed to accept 1.0” constant diameter axles, adapters could be used for other diameters(including the Anvil Tools geometry). This 1.0” standard holder would allow a variety of dummy axles instead of only one type.

I really don’t know anything about dummy axles, I’m just inquiring to move the discussion along:

- Can you link some of the other axles from the fixtures you are talking about?

- What is the advantage/disadvantage of switching to full 3/4 or 1in diameter?

For the sake of discussion these are the fixture “avalaible” at the moment:

I think all of them use Anvil style:

If you’re going to throw out the standard that is almost universal, you’d better have some damn good reasons.

And there might be some! But from where I stand, the existing Anvil-spec axles seem to work pretty well. Is there something I’m missing? What would the specific advantages of a larger diameter dummy axle be?

-Walt

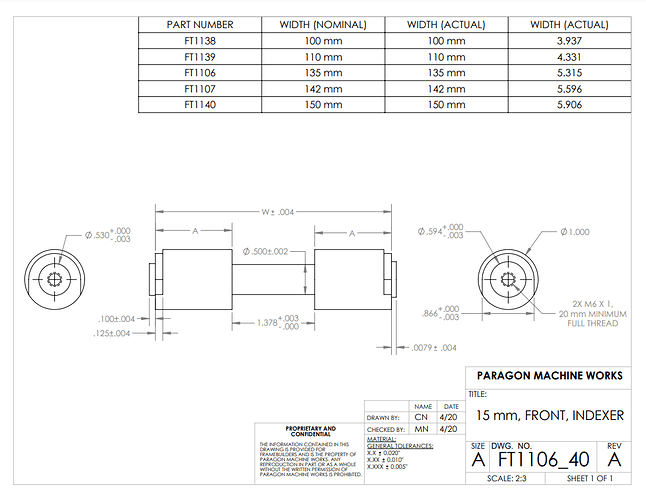

I’m also curious as to what the drawbacks are of the anvil style dummy axles. PMW is already producing a very similar design, and they cover seemingly all dropout types and widths for very a reasonable price. What is the benefit of a dummy axle that is constant diameter 3/4 or 1”? The narrow center section is a great locating feature and makes fixture set up pretty easy.

i thougth long and hard when i did mine and the reality was it didnt really matter it came more down to the nuances of manufacturing and the yield from production parts , we found some bars will bend in the middle when you machine the centre out of them due to internal stresses in the material (crap stainless usually)and thats about it problems wise on the machining front, im not convinced by that drawing though it doesnt seem to be constrained to the location datum whatsoever unless a is absolute or a box dimension,

I think there’s a typo for the nub on the right side of the drawing 0.0079 +/- 0.004 doesn’t really check out. Other wise A = A implies to me that the center section with its tolerance shall be machined with respect to the center of the W dimension. Maybe I’m way off though, it’s been a while since my days of working in a machine shop.

Don’t forget the Sputnik frame jig with its oversized dummy axles. It might be the only available frame jig with a different dummy axle design.

The legacy Anvil system is not in itself problematic. It’s sufficient for most purposes and the widespread acceptance has advantages. I an not suggesting that it be abandoned. What I am proposing is that fixture designs continue to offer support for that ‘standard’, but not be limited by that standard. Specifically, the narrow center section is the issue. A support for a smaller diameter is generally unable to support a larger diameter. A support for a larger diameter is generally able to support a smaller diameter.

There are alternative advantageous designs that either exist or could exist. The problem is that the narrow ‘standard’ axle support in fixtures prevents their adoption.

Good callout. Do you know what dimension their dummy axles are? Also… are they still in business?

Also, I forgot about the Engine Fixture which also uses the anvil/paragon axle

I am not saying I don’t agree, I’m just having trouble visualizing this. Do you have any drawings or examples?

What advantages are you talking about specifically? What would be better about a 1" diameter dummy axle in terms of actually building a bike?

I’m not trying to be a jerk, it’s just that it seems like there are no actual problems with the existing standard that could be addressed by a different design. Any advantage would need to be HUGE to justify a change from something that is nigh-universal and well regarded.

-Walt

Sputnik dummies have .750 centers. Yes, Jeff is still open for business.

.75" centers with 1" shoulders. You locate the axle by sliding the 90º corner against the holder, which means it’s possible to have a misaligned axle if you’re not careful.

That does not seem like a great design. Speaking as a space cadet/idiot, I need my fixtures to be hard to set up wrong, not the opposite. The more little things I have to remember to do the better the chance I mess up.

-Walt

In my mind, the important dimension of the Anvil (transferred to PMW) dummy axles is the smaller portion, 2" in the case of the rear axle. My fixture uses what amounts to a vee block. It’s as close to kinematic as I could figure out how to do with the resources available to me. I could use any diameter axle given that 2" dimension. Although the 3/4" is important for brake mount fixtures.

Tbh, I have been somewhat annoyed that people made some other design for no reason other than “not invented here.” Similarly, a couple of people have introduced post-punk style brake mount holders that don’t follow the post punk dimensions. We can all see they copied the design, just making the dimensions incompatible doesn’t hide that. Of course, OP didn’t do that, but he’s guilty of making his dummy axles incompatible. I recently added it up and I have about $1000 worth of dummy axles. There’s no way I’m duplicating that because someone makes a fixture I would like to have. I’d rather have some attachments to my post punk machined.

Fully agree. Anvil’s auto locating axles are superior.

I am deliberately avoiding any discussion about the advantages and disadvantages of specific designs. The point is that there are existing(or potentially existing) designs with features that the legacy standard does not offer. The fact that fixtures are limited to 1/2” diameter axle holders prevents these alternatives from being adopted.

It doesn’t matter if many people consider the legacy standard to be completely satisfactory in every conceivable way. They may continue to use it. The proposal is not intended to persuade anyone to abandon that system. The proposal is to suggest that fixture designers consider a larger diameter holder option for those alternative designs.

Why?!??!

Just tell us how bigger dummy axles will benefit us. Otherwise why start this discussion?

-Walt

Do a search for dummy axles and you will find a variety of designs. Ask those designers why they selected those designs. It’s outside the scope of this discussion to evaluate all of the advantages and disadvantages of those alternatives(or of the legacy standard).

Ok I give up. Good luck.

-Walt

it locates the same as every other axle goes in a groove hits a hard stop the only way its going to misalign is if someone hasnt cleaned everything up