Alex Meade also makes dummy axles of uniform diameter for the tools he produces.

I suggest that you design for a dummy axle of 1.00” uniform diameter and then offer an adapter for .50” ‘standard’ axles. Adapters can also be offered for .750”, and 20mm uniform diameter axles. That way your fixture will not become obsolete if a different axle design is introduced.

daniel_y

for my jig the axle has a shoulder 1.500" from the centerline of the frame. and the dia of the center section should be .750" and a minimum of 3.2" long.

Right, that’s a typo, It should be .079". I’m pretty sure it’s been fixed, but I’ll check.

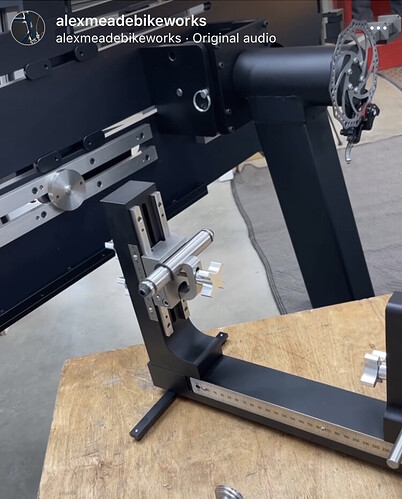

Since I built my own fixture, I might have gone with another design than Anvil. I could use a different design than anvil because what I do is put the axle in what amounts to a vee block. It so happens that one side of the vee is parallel to the major axis of the fixture. I got this idea from a precision engineering book, so it’s not totally off-base. Putting an axle in a slot is over-constraining it and mounting errors are easy. My mount isn’t kinematic, but it’s close and it’s not easy to have a kinematic mount for a cylinder that can take any force. I’m not sure what I would do if the locating feature was somewhere other than where the anvil shoulder is, but I’m sure I could figure something out as long as it wasn’t closer than 1" to the center.

I understand why people don’t like the Anvil design. I’m not particularly fond of it either. But I’m sure I said already in this thread that I think it’s good enough. If you bend one it’s your fault and they are easily ordered. I have never managed to bend one.