Ceeway should be able to get the needed reamer. I have always gotten my Cyclus tools,thrpugh them or a Europe based mail order shop.

We’re getting quotes, but haven’t heard anything yet. Stay tuned!

Thanks Mark and team!

For the next gravel build, I am aiming to use a EC37 head tube to reduce weight. But the hunt for a fork is rather surprising.

The availability for 395mm (or longer), 1 1/8 - 1 1/4" with a spacing for 50mm tyres (w or w/o mounting holes on the side) is very very limited.

I found one from Ritchey w/o mounting holes: Ritchey WCS Carbon Tapered Gravel Fork | Ritchey Logic

The COLUMBUS - FUTURA GRAVEL GABEL is limited to 40mm tyres.

With the limited availability of off the shelf forks I can’t see EC37 head tubes on gravel bikes, or rather very limited.

If 50+ is your target tire clearance then you’d be better off building the bike with a standard 1 1/8" headtube and using one of the forks below.

Wilde Wayfinder Fork

Crust Carbon Fork

Wilde offers Builder Pricing but I don’t believe Crust does

If there are 1 1/8" carbon forks that meet the design constraints then I think it’s the better way to go in every way. I see EC37 as a solution to use the many 1 1/4" Tapered forks on the market. If manufactures made 1 1/8" Carbon forks then I would just use those.

Unfortunately, this is one of those chicken and egg problems. I currently am working with a brand (Merlin) to introduce EC37 bikes and 1.25 tapered forks. They have a design for a carbon gravel fork with 1.25 taper and 50mm clearance, but can’t pull the trigger to cut the mold because we are wary of the demand for external cables.

I don’t like letting marketing and consumers decide how bikes are designed, but unfortunately, when dealing with $30k of investment to run the forks, there has to be a business case. Modern 1.25 tapered forks may take a few years to come online (or they may never). But if we don’t try now it will never happen!

Our plan is to bring an externally routed EC37 and internally routed EC44 bike to MADE to see what the media and public thinks.

Just for reference, from a fork supplier:

Mold tooling fee: US$2600

MOQ: 100pcs per model per order

The order processes are simple:

Confirm the design drawing and make the quote.

Issue an invoice and make the payment.

Start the mold tooling.

Sample made and tested in house.

Send you a sample to check and test on your end.

Start the production once the sample is proved.

It’s going to take a big chunk of capital and 6mo to go through this process. I still believe we can make it happen, but it is going to take time to get all the stakeholders and customers on board.

This is a case where a builder could use an EC37 headtube with a headset to fit a 1-1/8" steerer (assuming the headset is available). Later on, a 1-1/8" x 1-1/4" steerer could be swapped out if the rider wants to.

I just talked/e-mailed with my existing gravel fork supplier oversea. He mentioned he could add an adapter/washer on the existing mold, to fill the space to 1 1/2. No need to develop a new tooling and no MOQ. Just waiting for a quote now.

I still have my 1992 Tassajara with EC37/EC37 and 31.8 steerer tube, and when I look at it, I can’t help to think how ahead of its time Gary Fisher was. Maybe they are right and you don’t need a 1-1/4 steel steerer tube, but I always wonder how people “gets” the need to change tube diameters in other parts of the frame when going for aluminum or titanium, and still think the same 1-1/8 size steerer is appropriate there. It reminds me that, at one time, suspension forks were all made with the same rake as a cost saving measure. Always 50 copies of the very same thing, with just cosmetic changes, rather than offering real diversity based on technical necessities. The bike industry is so prone to that.

Well, it depends on the kind of machinery you have access to. If it’s an odd job once in a while, nothing beats an horizontal milling machine with a boring head.

Also the best way to size a seat tube collar after fab.

Actually there is. As I wrote in another thread - I’ve successfully used a starret one:

and probably this one will be even better:

I know they are far from “fine tooth” but with high rpm they work good.

I am late to the party, but (fwiw) I am completely on board with a EC37 standard and 1.25 tapered forks.

I’d also echo what Mark said regarding 1-5/8" titanium tubing for 37/37 headtubes; it seems like a no brainer to me.

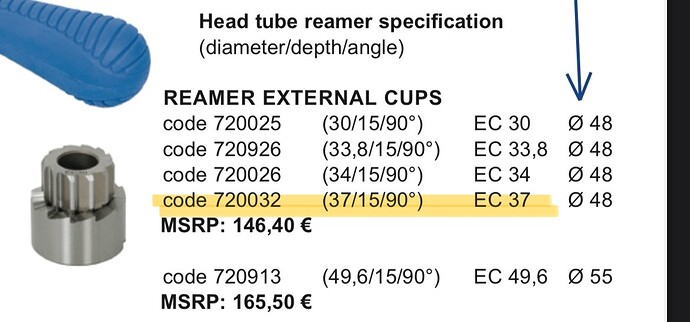

Has there been any word on if a reamer is available for 37mm? I have a build I’m tallying up now and would love to use the 37mm HT if I can get it reamed…and find a headset for it.

I think Cyclus makes one if I’m reading their 2024 catalog correctly. Peter at Ceeway can probably get one to you if it’s a part that actually exists.

Promolloy do a 4130 tube that is OD 41.3 x 4.0 wall for those wanting to run a straight head tube and EC37 top and bottom. Not mach wastage from machining there.

We are inquiring about having these manufactured for us by a reamer company. All in the talk stage right now, but stay tuned. If you have a deadline, then you should pursue the Cyclus tool.

Headsets are currently available from White Industries.

@Daniel_Y is having a batch produced, but I don’t know the status.

Samples landing this week!

Thanks everyone for keeping the EC37 dream alive. I have a few 2024 projects to build on the momentum.

Will that work with a Park reaming tool?

Good question, I only have the Cyclus tool so I’m unsure about compatibility with the Park handle. Peter at Ceeway may be able to answer (he’s very responsive in my experience). I vaguely recall seeing someone make an adapter for the two of them?

Edit: here’s the post I was thinking of - credit to @normaali.

This is what the interface looks like on the handle if that helps.