I just made my follow dies with a 3 hp router and a very simple plywood jig to hold the work and use as a fence.

Just be careful about putting too much load on the Cobra Toob bender - it is possible to bend the bender! (Don’t ask…)

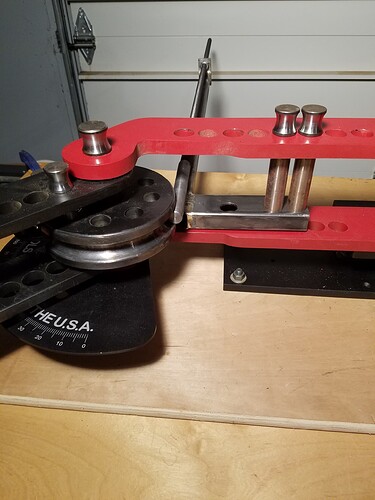

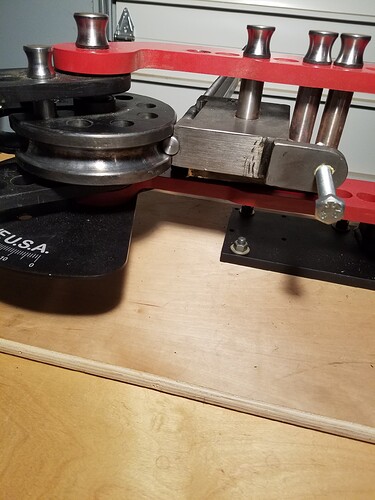

I wanted to make tight radius bends and wound up going with a Pro Tools 105 bender. I added an internal mandrel so that it would accommodate thinner wall tubing. It is set up for 3”CLR 5/8X.035 or .028, 3”CLR 3/4X.035 and 3”CLR 7.8/.058 (for chainstay half yoke sleeve) The mandrels are made for each diameter and wall thickness and I will likely make another one for thinner 7/8” tube. Each mandrel is on a piece of all thread. that makes it easy to adjust the mandrel depth. I got the info for calculating the mandrel diameter etc. from bendtooling.com. I use a trailer tongue jack with a cordless drill or a wrench to power it and that works very well. I use a tube block and digital angle finder to clock the tubing from one bend to the next. I found out that it is pretty difficult to put on the tube block with the top and bottom exactly parallel so I make sure to keep the angle finder on the same side of the block. If I do it again I will set the mandrel frame to hold its position relative to the pressure die and not the bender frame but it works well as is.

Thanks

If it’s not cool to post a link to a FB Marketplace ad, lemme know. A friend of mine is selling his Diacro #2 bender, with some dies. He’s a metalworker, not a framebuilder.

I can run over and get pics if anyone wants more.

I have some 22.2mm (7/8") titanium 3-2.5 Grade 9 in 0.9mm thickness tubing for chainstays I’m looking to put some bends in for the chainstay.

Do you think this set up of the Vevor would work with that? I haven’t bent titanium before and from the research, it seems a little more challenging.

I was hoping to be able to do it on more of a budget than getting a Toob bender.

Thanks

Toby

I wouldn’t be super optimistic about that, but I’ve never tried that style of bender in person.

If you end up not being able to bend it with the Vevor, I’d be happy to mail you some bent ones at cost, I think I have enough spare 22.2 x 0.9mm Ti kicking around.

I was able to bend some 7/8 .047 wall chainstays last night with good results on the vevor bender. I did make an aluminum follower bar and clamp block similar to what @Seriousbicycles has done. Out of the box it would likely put some bad kinks/ ripples in the tube

What happened? Maybe you could expand a bit. That’s a serious tool to bend!! What did Joe say?

Never bent Ti with the vevor.

I would imagine the bender it self is. robust enough to do the work but the clr would be too tight. You would also need a pretty big cheater bar to get enough leverage.

For NMW bikes, we typically use the Cobra 230mm CLR (9in) die as much as we can. My reasoning is because 1) I think it looks better and 2) I want to cold work the tube as little as possible

Merlin uses the 115mm CLR die on 22.2 titanium to get the clearances they need for gravel bikes.

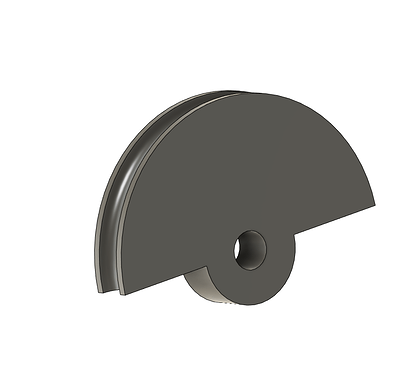

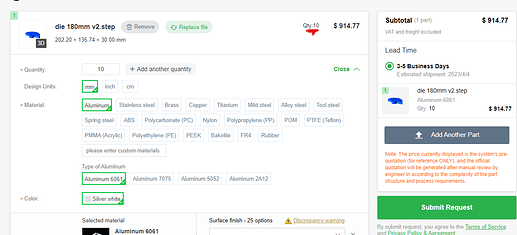

I eyeballed/measured our Vevo bender, and I think if we were to design a custom die and follow bar, there is room to make a 180-200mm CLR die for 22.2mm and 19.1mm chainstays. I think the less aggressive bend should make bending easier and give the highest chance of success.

I did a really rough design to get an idea of the pricing:

My guess for a hot-rodded follow bar and die for the Vevor bender would be ~$200/per size. If it works well, $500 for a bender that can do SS and CS is not too bad.

It was a dumb mistake on my part. I failed to move the pivot pin to the corresponding radius hole after changing the die. So then I proceeded to bend using an 18v brushless drill to drive it, which will put out a decent amount of torque, and kept going when I should have stopped. Oh, the material I was bending wasn’t standard tubing either. It’s some experimental stuff I’ve been working with the local university to test, so at first I thought it was just some tough sh*t. Once I realized what was happening, it was too late. The follow bar was damaged, and I thought that was it. Contacted Joe to see about a replacement and he just threw one in an order I was placing on the house. Can’t beat that customer service!! Some time later, I pilled the arms off to drill peep-holes for lining up the tangency point. That’s when I discovered the arms were slightly bent as well. But after looking at it a while, it doesn’t really effect the operation, so I have just been using it.

In summary, totally my fault, always check your setup, stop if it seems wrong, and Joe / Cobra Framebuilding are awesome!

I did the same thing once, once. Starting bending a new tube on a new die without moving the pivot. Not good!

Joe is the best for replacing the stuff I mess up ![]()

I have also done that, luckily just made a nice divot in the die.

I too have done that! Haha. Thanks everyone for making me feel better about it!

I don’t have the vevor bender but I’d like to make a follow die for it. Would you mind posting the dimensions and any relevant details?

Thx

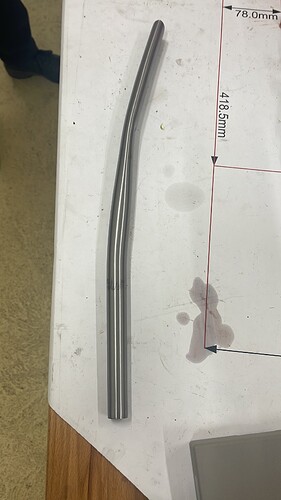

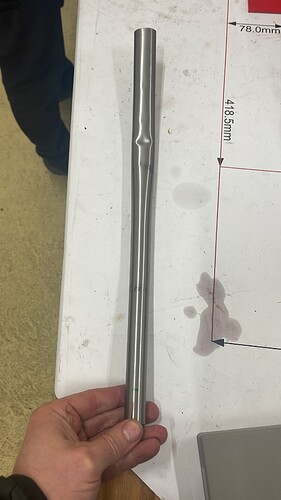

We are in the process to make our own CS. We source a straight titanium tube with 0.9mm wall thickness which is tapered 19-22.2mm (transition over 19cm and then constant. Also we need to have the CS partially oval with two bends, whereas on bend is on the oval part.

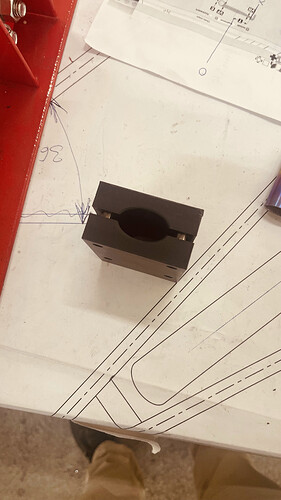

I printed (PLA) a bending die, a follower and the small holding block. I printed also an ovalization die set.

We started to ovalize the tube which worked ok. Some small ripples because the die was too short and we had to move the CS in the die a few times and press again. Ovalization tests with longer dies worked ripple free and much better. Will change again to the longer ones.

We build the tool bender with our custom dies and did the bending. It didn’t work out too good and we got a kink. I assume the accuracy of the oval tube was not good enough for the oval bending die and process. I had a small difference between both dies (oval and bending) and next time I need to make sure the values are tighter.

Next step: I will print a new set of ovalization dies which have a smaller slot, to be more accurate but also check the measurements before going into the bending…

![8464CC98-6D42-4F94-84F0-42873F4A7596|281x500]

![6E3D29B7-B22E-479B-BBD2-1BF03A71FEAC|281x500]

I have this in my cart since a while, will definitely follow in your footsteps about modding it! From the few reviews out there it seems that everyone had the same comments about the tube holder, definitely it’s the first upgrade - Thank you!

New bender from HF. Wonder how it will do for CS.