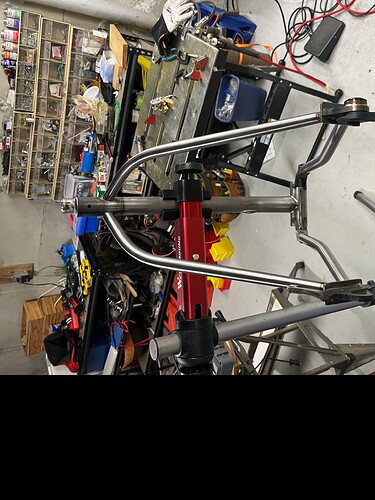

Specs and some lessons learned from a recent fat bike build. This was frame #3 for me, so very much still learning how to do this.

The numbers:

HA 68

SA 74

FC 780

RC 430

WB 1210

ETT 670

BB Height 315

BB Drop 69

Axle Height 384

BB to Bar 835

Stack (to c of bar) 995

I designed it to have a 67° HA, but ended up with 68°. I’m assuming the discrepancy a mix of deformation and incorrect spec on the fork. I rechecked the jig setup, and it’s correct.

I’m wondering if I should do all the brazing on the down tube before I cut the miters? The DT has two sets of bosses and three cable guides. The last frame I made I cut the miters for the DT, then brazed the bosses, after which the miters were no longer tight. Maybe I’m using too much brazing heat?

The bike rides how I hoped, and feels great. I’ve only had it out in ideal firm snow and dirt so far, we’ll see how it does in squirrelly soft snow.

Because the geometry isn’t dynamic on the full rigid, I’m guessing the 68° HA rides similar to a +/-66° on a bike with a suspension fork, so the 1° steeper may not be a bad thing.

I designed the dropouts, using send-cut-send and a friend with a CNC for fabrication work. They use a SRAM UDH. I hand cut my miters, and the flat landing plate makes it easy to get a tight joint. Not the lightest dropouts, but cheap and they work great. Integrated ISO mount saves some steps and potential alignment issues.

The yoke is a variation of the $10 yoke designed by Benjamin Land. All the pieces were cut and bent by send-cut-send.

Lessons:

My welding skills are very much still developing.

My heel can hit the seat stay if I’m twisting my foot a bit. I should have landed the seat stays higher on the ST, or given them an S-bend (though I don’t have a tube bender). I’m going to measure my heel locations and add that to my frame 3D models to be sure I have clearance on future builds.

The SRAM FAT5 chainline is too wide. The cranks come with a -4mm offset, which was way too much cross-chain in the granny gear. I swapped for a 0mm offset and it’s much better on both ends of the cassette. Overall I’d say the SRAM q-factor is a bit tight for a 197 rear end.