I’ve built one frame around the Bear Frame Supplies flat mount dropouts and liked them quite a bit. More than worth a recommendation.

Question related to Flat Mount.

Both the SRAM and Shimano tech documents specify that the mounting thickness should be at least 10mm. Seems a bit overkill to me for steel or Ti frames and I’m thinking it’s more related to carbonium.

Considering there are Post Mount to Flat Mount adapters from A.S. Solutions and Wolftooth that are significantly thinner than that, you’d think it would be fine to slim it down a bit.

What are your thoughts about this?

Yes. You could go down to 5 ir 6mm in steel.

It’s a good question, and I can’t think of a reason why it wouldn’t work. Even the fork flat mounts are ~6mm of aluminum

My only concern would be the stiffness of the brake interface. If the mounting plate is cantilevered, it could give bad brake performance. But I honestly have no idea.

I was thinking about the cantilevering as well, but many mounts either have full or partial support around the mounting area with only a recessed hole for the bolt & washer. The ones I have in mind designing will have supporting ribs much like PMW BK2070.

Ive just done a version of using a FM/PM mount using an FM140 adapter for a 180 disc. Idea being if they want to use a 200 disc they get a FM160/PM adapter. Main issue though is it means drilling out the adapter as I thread into the frame mount. Not sure if thats a go or no go. Not hard to do but may turn some customers off. We know how finicky they can be. Given how light Ive built some IS mounts my gut feel-o-meter is confortable there is more than enough in the frame mount.

Looks like it should be modular enough.

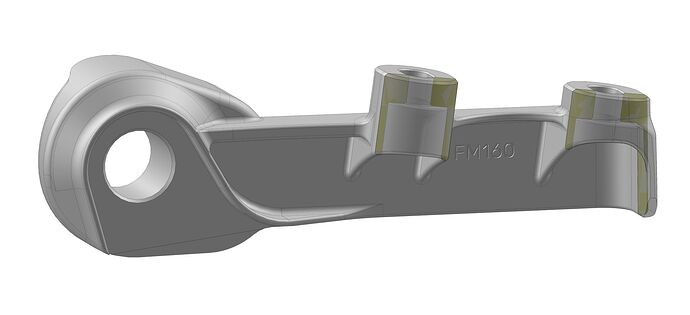

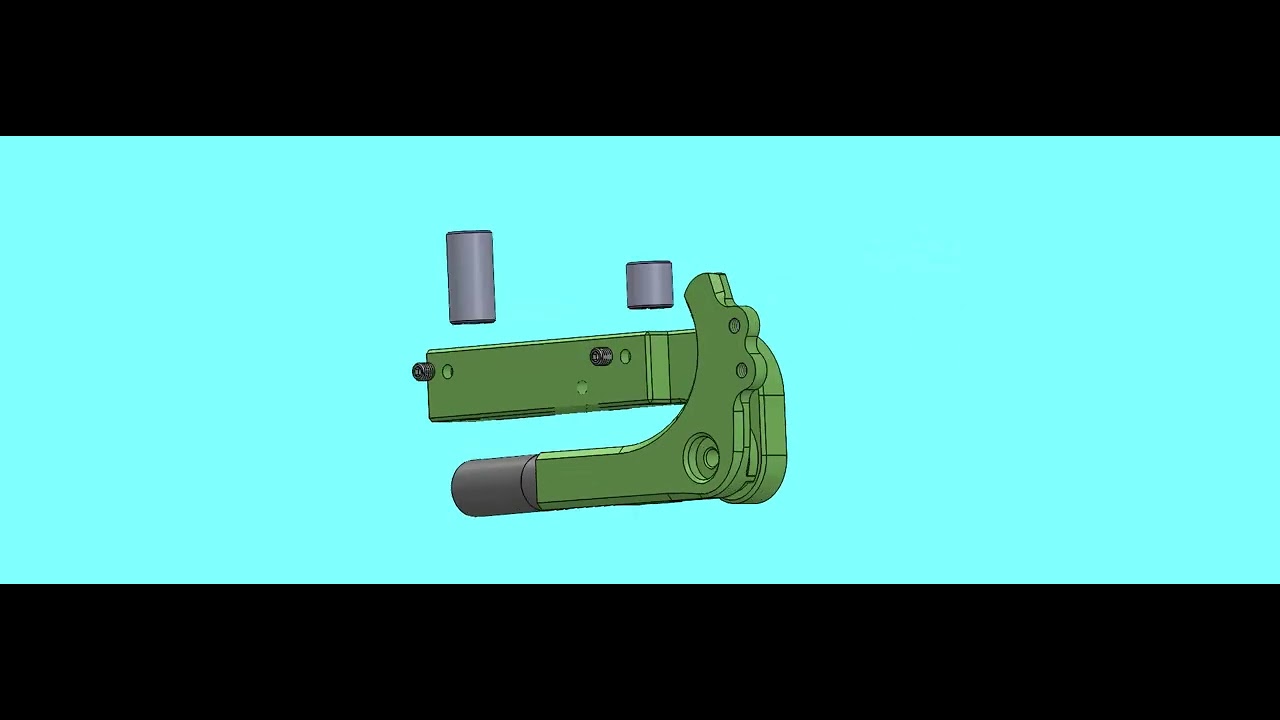

This is what I’ve been working on. Just seems unnecessary to make the material thicker in that area.

Its a bit rough to prove my idea. I’ll sit down and model something nice up soon. I think your approach is sound though and definitely don’t need much material. Steel and Ti is super strong when thete are little stiffeners everwhere like you have in yours.

That design looks great! Is it going to be 3D printed?

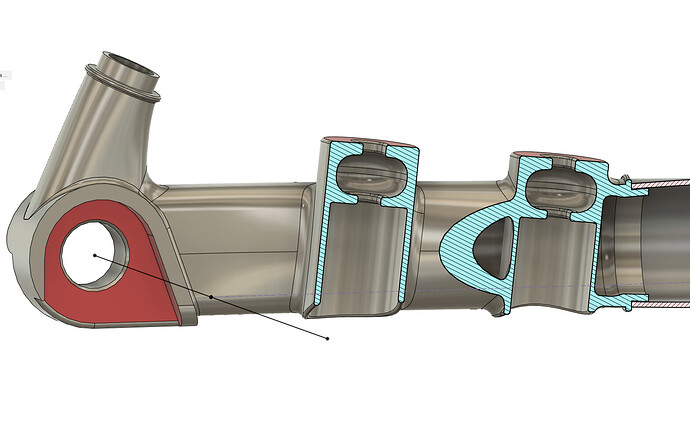

For reference, this is how I got around the 10mm spec:

I don’t foresee any issues with your design

Thanks!

Yes, the design can be 3D printed, but will likely be investment cast once we’ve done all the due diligence to ensure it’s a sound design.

Hollowing out the mounting base is a great idea to adhere to the official spec.

I got an answer from a SRAM engineer about the 10mm spec.

One aspect of the thickness requirement is that a longer bolt will have more elasticity and thus be able to retain its tension better.

Though considering front mounting plates are 5mm thick, I doubt it is a real concern for this application.

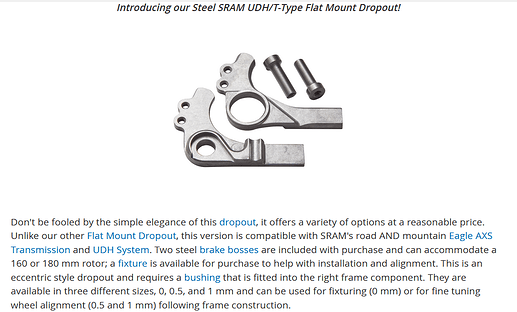

This dropped yesterday:

https://www.paragonmachineworks.com/news

We had prototypes at the MADE show, #steelisreal now available. We will do stainless and ti if there’s demand.

This one has some features we like:

Price: $70 no eyelets, $75 with eyelets. You’ll need a bushing as well, that’s another $12.50.

Uses the front-style flat mount, 160/180. The adapter for this is reversible, so only one part is needed for both size rotors. Post mount adapters are available, so that gives riders options.

Uses a stainless steel bushing for the UDH/T-Type 20 mm hole. This makes a clean mount, with no corrosion problems. Bushings are available concentric, or with .5 mm or 1 mm eccentricity, making it possible to fine tune the wheel position after fabrication.

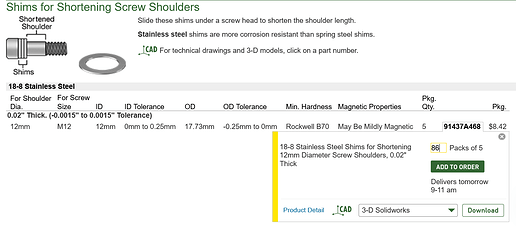

If you want a stainless steel interface for the skewer, these washers are available from McMaster-Carr:

The front brake boss intersects the stay, so the length of the tab is shorter. We offer a locating fixture that doubles as a drill fixture, so that the 5/16" mounting hole can be done with a hand drill if desired. This is particularly good for builders who do not have a milling machine.

The brake bosses are simple, and can be custom made by the builder for their application.

Eyelets are available, and they don’t interfere with SRAM’s clearance mask! Use the top eyelet for racks, and the lower one for fenders; the bolt must be flush with the inside face.

Chain and seatstay plugs are available to make the transition to the dropout:

Because of the width of this dropout, we recommend that the plugs mount on the inside of the dropout face.

If you use this dropout, please post photos and comments of your build.

When will these be in bikecad @BikeCAD ? I am setting up a new gravel frame now.

Totally spaced that out! We’ll get on it.

I apologize that the next update of BikeCAD keeps getting delayed. It’s very close now, but I will make sure this dropout is added as well.

Interesting how you got around the 10mm spec on the mounting boss. Because otherwise you’d need custom bolts.

I’m also looking at dropouts as the current offering are mostly too heavy as they are based off specifications which were probably intended for aluminium and carbon dropouts.

Getting shorter bolts to fit is not huge problem. Standard M5 bolts in the approriate length for the mounting boss, even if the thickness is less than 10mm, are not hard to source.

The lightest possible (overall) flat mount dropout in steel will probably be the kind where the FM bosses are separate from the dropout.

Semi on topic:

Does flat mount work with tapered chainstays (22.2-19 titanium)? By “work” I mean can the tapering / reduced diameter cope with the brake forces?

Love the look of these dropouts. I have been designing something similar myself using laser cut parts. One thing I haven’t figured out a simple solution for is the 3.5mm offset for the brake with 142mm and 148mm hubs. What width hub are you running with your design?

I had a friend machine the offset into the non-drive side dropout. I’ve thought about making the dropout from two pieces of laser cut sheet, then brazing them together to create the offset, if that makes sense. You’d have to use 0.125" (3.18mm) thick sheet for the offset, so you wouldn’t get the full 3.5mm.