Here’s part 1 of Financial Planning for Framebuilders. It’s a quick overview of why these exercises could be important for a builder, along with some key concepts and terminology.

Why perform these exercises?

The best decisions are informed decisions. Better information = better decisions.

You can wing it and just take a guess at things like price setting. You might get close, you might not. There is an inherent risk of uncertainty. These exercises help mitigate that risk. You can have confidence that as long as you stick to the plan, you will achieve the planned results.

The crowd in this forum is quite diverse. Everyone will have different risk tolerances based on a number of factors. That’s great! Take what seems useful to you, and don’t spend time doing what seems unnecessary. For the most part these exercises will be geared towards builders who are at least partially relying on this income to support them, and correspondingly have a lower risk tolerance for financial uncertainty.

What’s the plan?

We’re going to create pro-forma income statements. These are just revenue and expense projections.

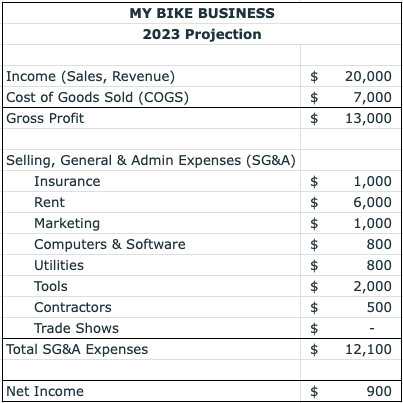

Income statements (also called Profit & Loss statements, you might see me refer to it as P&L) follow the format below:

These are just quick numbers I made up, this business is not very profitable lol. But I actually bet there are a lot of builders out there that have something similar to this.

Another way to view the P&L is to recognize that it is split between variable costs and fixed costs.

Variable Cost (and income): This number is driven by the number of units sold. If you sell more units, sales and COGS will go up. If you sell less units, sales and COGS will go down.

Fixed Costs: These numbers are considered fixed because they are not driven by the number of units sold. Example, it doesn’t matter if you sell 5 frames or 50 frames, your rent and insurance will be the same.

In future parts of this lesson series we’ll dig into the best ways to estimate the variable components, including:

COGS

Two methods of Owner’s pay

- Just use the Net Income - Basic but essentially effective. COGS is the cost of material only.

- Build labor cost into COGS for each bike. This involves assigning an hourly rate for your time and using time studies (estimates) to allocate into the cost of each frame. The major benefit here is you will be able to see how your time is being spent on different aspects of a build and the related cost associated with that time. COGS will show the combined cost of materials and labor, which is much more insightful. You can also see things like the cost of time spent designing, fabricating, welding or brazing, finishing etc which can help you establish your fees for custom work.

Income and Price Setting

Depending on how you handle owner’s pay there are a couple different ways to calculate price. The gist of any method is to ensure that your price adequately covers variable costs, an allocated portion of the fixed costs, and owner’s pay.

Fixed costs are pretty straightforward, just estimate what you’re going to spend on each for the year. It’s the allocation part that’s a little (but not a lot) trickier.

I’ll also create an Excel Template (can be opened in Google Sheets) so everyone can just plug in numbers and see how it all changes. If i’m feeling very motivated it will be capable of a product mix so your projections can can establish different costs and prices for different bikes or stock vs custom.