Hi all, new to this form.

Just wanting some advice from anyone who has experience building a BMX frame, or similar bike frame.

I want to fabricate a 20" BMX frame out of chromoly steel, as a prototype to see if I can make one to high enough quality to sell, and potentially start a custom bike company.

I’m having trouble with the dimensions of the chromoly though, and thought maybe someone here could help, or at least give me some insight.

I need:

Ideal wall thickness, Ideal Overall Diameter, and a rough estimate of what length/s I should order the steel in.

Keep in mind, I’ll need the frame to maintain a decent strength-to-weight ratio so that it’s lightweight and durable enough to be used for freestyle BMX.

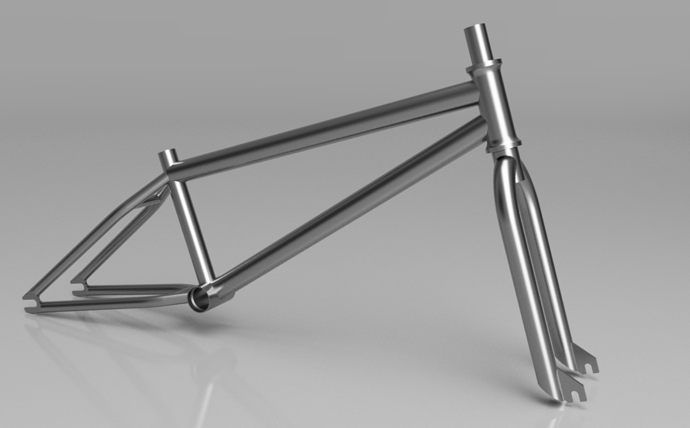

I’m not an expert on BMX, but I also want to build a frame. Here’s what I’ve found out: There are BMX specific tubes available through @BikeFabSupply as well as from S&M Bikes. There is the opportunity for custom design through dropouts and other braces using laser cutting services like Send Cut Send. I know LairdFrame makes custom seat stay bridges on his bikes. Again, I’m not an expert, but this is the design I have cooked up. I do need to revise a few details, but this is how it should end up.

I don’t trust myself to make a BMX fork yet, so for that I’ll just swap the fork off of my current BMX bike.

2 Likes

Your questions are good but really, really general.

It is worth doing preliminary research and referencing “primary sources” and giving us all more context before posting.

I don’t mean to be harsh but there’s so many things that are driven by design, intended use, user, MFG capability, budget, etc. A specific answer w/out having specifics could be problematic for you.

It’s kind’ve like saying the following:

I want to put something together. What screws should I buy?

As Spencer suggested, going to supplier + brand sites is a good way to start. It might be worth contacting a few brands and seeing if they’re forthcoming with their tubing thicknesses, butts, etc. e.g. I called up a company not too long ago just to confirm if a tube was butted or straight gauge. Since it was a repair, they were happy to share the details + approximate butt locations. In the end, we just decided to use a 34.9 x 1.25mm tube (because the dude was riding vert).

5 Likes

Bikefabsupply sells BMX specific tubing. That would be a good starting point:

From what I see, most people laser cut their dropouts.

After doing a bit of research, I would reach out to BMX builders directly with questions. People are all friendly and willing to help.

Someone on the forum recently posted about S&M’s Factory Friday videos. I have found them both entertaining and helpful, even though I don’t build BMX bikes!

Laird does some crazy volume: https://www.lairdframe.com/

Kahl is a smaller BMX builder: Jackson (@kahlbikeco) • Instagram photos and videos

Happy hacking!

1 Like

Bike fab Supply is a good start for the machined parts and dropouts.

Straight gauge 4130 tubing is fine to use for BMX frames. The following tubing specs suit anything from street to trails but can be lightened up for race only duty.

Tubing wise:

SS - 3/4" x .035"

CS - 3/4" x .049"

ST - 1-1/8" x .058"

TT - 1-1/4" x .035"

DT - 1-3/8" x .049"

4 Likes

First off, welcome and thanks for posting! Hopefully this will get you where you need to be to ride your first homemade bike.

Once you’ve done your first frame, you won’t know anywhere near enough to know if it’s good enough to sell. You’ll need at least 20 frames under your belt before you can even think about selling to the public, though maybe your mates will buy the first few. You need quantity to get quality.

That’s a big jump, that’s step 6,004 and you’re on step 28 (there are a lot of steps).

Start by making your own bike, ride it, break it, learn something new. Do this a bunch more times, get some other folk to ride your bikes. If you really want to make a career out of it, start your social media now and get followers (sadly it’s hard to do anything these days without followers!). Once you are either starting to make money or need to spend a lot more money to get to the next step, then think about paying others for their services (marketing, machining, maybe even building the whole thing).

But for now, just focus on making a metal thing you can bolt stuff to and ride around on. Especially for a first frame, I’d focus less on material choices and precise geometry tweaks, and more on quality cutting and welding. Buy some cheap tubes as mentioned above (straight gauge or cheaper butted ones, so you don’t throw away all your money when you cut something too short or burn a hole in it). Make a frame that is strong and straight, you can ride a heavy bike but you can’t ride a broken one! And remember, BMXs weighed 40+ lbs no so long ago. You can iterate your design (tubes, geometry, etc) with number 2 and keep going from there.

8 Likes

THIS ^^^ so much!!! Make your first bike first, then tweak the sh*t out of it afterwards.

BMX bikes cost less to the consumer than you think, unless you know a pro team or have an “in” with other BMX riders. My hubby and I own a local BMX shop in the SF Bay Area and it’s a tougher market to get into than you think.

8 Likes

Since I started frame building as a hobby, I’ve had friends ask me when I’m going to start selling frames. It seems to be the first thing that comes to some peoples minds. It’s difficult to explain to them that I’m light years away from even considering that idea.

7 Likes