Hey guys,

I’m a software engineering guy from Belgrade, and I love cycling. I decided do make a carbon frame, and I want to do this as a hobby project. My goal is to make a functional, and safe frame. It does not have to be pretty, I am not optimizing for the cost, I am optimizing for a fun and learning experience.

I was actually inspired by @Sideways_Viola, @Lester and @Pol. This forum seems like a great place to do a build-along, and get my thoughts peer reviewed.

I chose carbon because I started learning about composite materials just for fun and I’m really enjoy the topic, so it seems like building a carbon frame is a natural cross section with my passion for cycling. And it honestly looks like carbon fiber has a lower barrier to enter than welding! That is the only constraint, I am willing to change anything else based on your guys feedback!

The bike’s mission: I commute to work every day, and on weekends I like do to like 50km or 100km loops, away from the city. It’s usually all paved, or cracked pavement like 95% of the time. But in the summers I like to shred the hills of green Šumadija where you can’t avoid segments of doubletrack (with huge grain size). So I want to do an All-Road geometry, with big tire clearance.

Current design:

- I usually switch between 700x32 tires, and 700x47, so naturally I want to accommodate that bigger tire clearance with my new bike.

- Rear axle - thru axle 12x142, as I already have a wheelset

- BB86 - I want to go with pressfit, in order to minimize the need for carbon to metal bonding, as every carbon-to-metal bond is a possible failure point. I want to go with bb86 specifically, because it’s kinda wide, which I believe gives me more options when designing the chainstays.

- Headtube - ZS44/28.6 | EC44/40 - So a straight tube 44mm, again press in cups because it seems safer. Also it’s a straight tube as it seems easiest to produce, and I have a fork ready as well.

- Integrated seatpost - I wanna go with an integrated seatpost because I guess it’s one less worry, getting the inner diameter of the tube right. I am aware that seat mast topper offering is slim, but I guess something can be hacked up here. I actually skimmed through some forum posts saying this is possible.

I managed to source some cheap tubes from m-carbo.

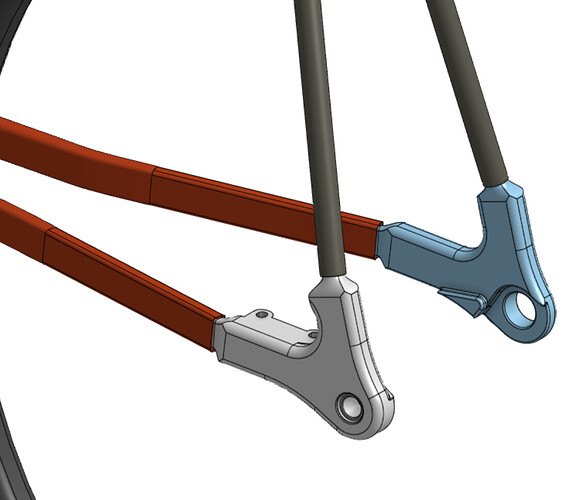

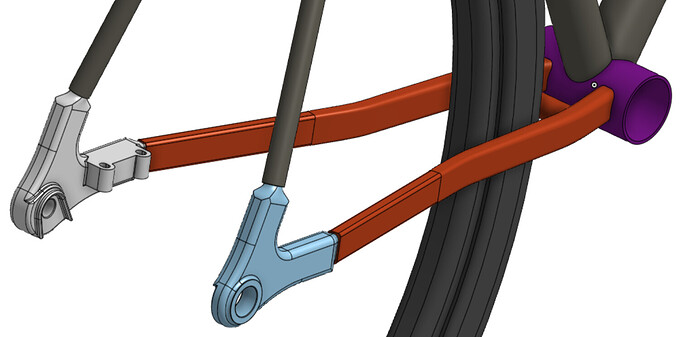

Current plan: Initially I wanted to go down the lugged frame approach, where I would somehow create carbon lugs and then bond the tubes to the lugs, however based on some feedback I decided to switch focus to mitered tube-to-tube design, with roll wrapped lugs. So the general steps are creating a jig, mitering the tubes, creating bb and headtube cylinder, bonding tubes and those parts, then wrapping. Because of tire clearance I will have to do a bit more complex chainstays, for this I am considering doing a foam core, or 3d printing with abs, and then wrapping carbon around, and then dissolving the core in acetone.

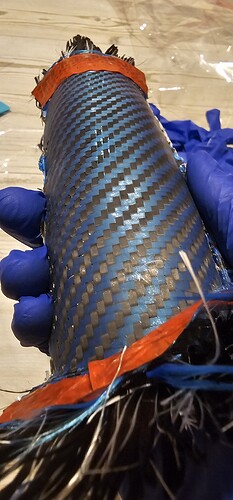

Before I start building the frame I want to practice the wet layup on something simpler, so I decided to try to make a carbon mudguard for my 47 tires.

Current progress:

- I designed most of the bike in onshape. I still need to design the dropouts, and I actually need to think more about how I will do the entire rear triangle.

- I bought the jig from Simple Bicycle Framebuilding Fixture by ideas2cycles

- I’m waiting on some aluminium extrusion which I will need for the jig.

- I’m waiting for carbon tubing from m-carbo to arrive.

- I sourced some epoxy, mold release.

- I bought some carbon, and ancillaries from easycomposites.

- I have to pick up some 3d prints of a mold I designed for the mudguards.

- I started contacting some cnc shops to see who can help me make precise metal mandrel cylinders for BB shell and Headtube.

Basically I am still buying stuff and planning ahead, trying to decide as much as I can upfront.

I just wanted to kick off this intro post today, I will followup with more thoughts and questions, as I like thinking about all the details of this project, and for every step of the way so far I have so many things I would like to double check.