Less specifically, I suggest designing around a 1x gravel drivetrain. It gives you more wiggle room to design the tire clearance while maintaining <430CS.

1x drivetrains have more range and are way more robust than 2x gravel these days. It will make your chainstay sub assembly simpler!

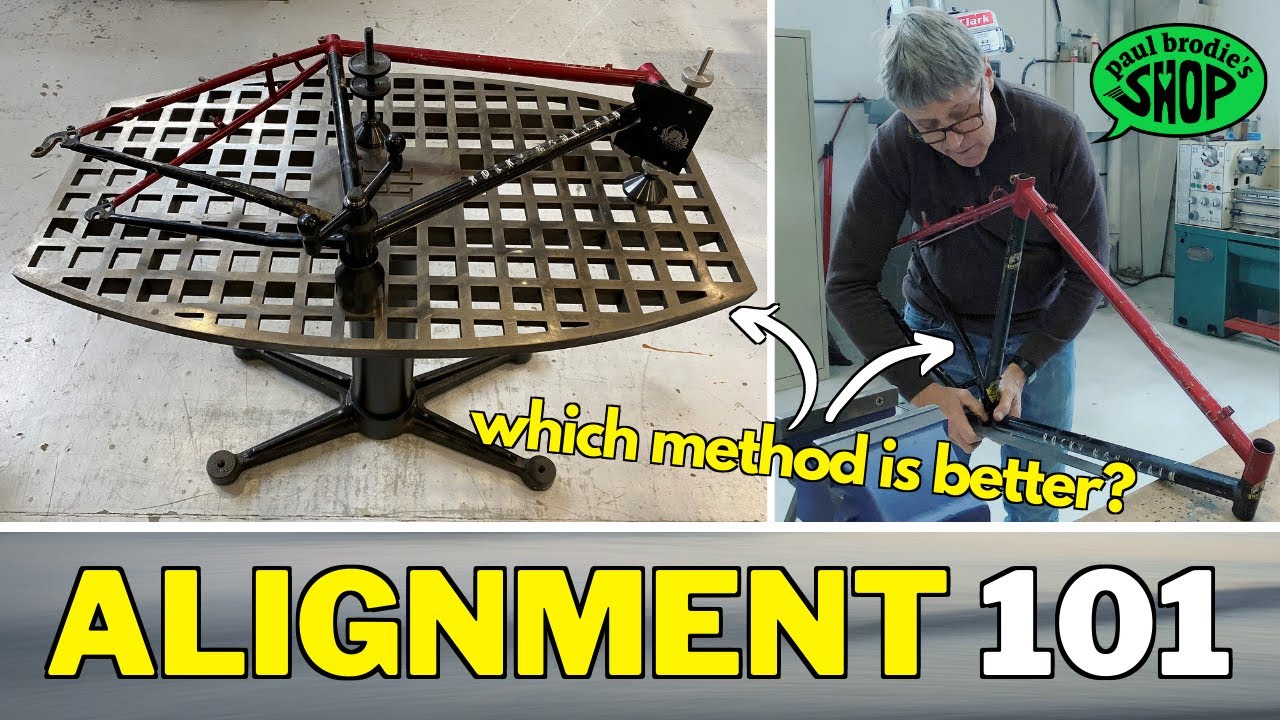

For a DIY setup, the weight of your kit is a consideration. The flatter and more precise all your surfaces are, the straighter your frame will be. Realistically, you are trying to hit +/-2mm and +/-.5 degree. Plus, as Paul Brodie shows, even with a flat surface, it is debatable what is “straight”:

My thinking on alignment has evolved over the past two years. To me, one of the conclusions of the alignment thread is that in modern frame building, (front triangle) alignment does not really matter. A few things to consider:

- Tube diameters are much bigger now, meaning the front triangle cannot be cold set. There are plenty of photos of frames that buckled during alignment

- The point of reference for frame alignment is the BB shell. which warps and distorts, making it a bad ground truth. If your BB is .1deg out of parallel, the HT will appear to be 1mm out of plane.

Framebuilding is a hobby, and if chasing perfection is part of the fun, go for it. I think as long as your miters are tight and you critically think about your weld/brazing sequence, your frame will come out fine.

Perfection is a process

I always fall into the trap of wanting everything to be perfect before I start a project. I have to remind myself that things will never be perfect. First one will suck, the second will be better, third will be great.