Talking platform-style front racks here. More specifically, platform racks that are mounted to fork at the crown and a midblade eyelet, no strut running all the way to the dropout. For extra heavy duty porter style racks I run a strut (or struts) to the dropout to support the rack fully, but these racks stiffen the fork considerably, and one of the goals of the platform racks in question is that they avoid that.

How do you choose to have them mount to the fork? I build racks with 3/8th cromoly for all my custom frames. I have made racks with 3 points of mounting as well as 4 mounting points, and have not had failure on any, even on my own 3 point racks which I have overloaded to the point of making the bike unridable, as well as crashing hard. There are times I worry about my racks that use that singe mounting point in the crown- if it fails while loaded on a rough road it can lead to very sudden wheel lock up. The easy way to reduce this risk would be to only build racks that use 4 mounting points, but my frames are lugged and my customers are into their fun carved fork crowns, so I try to have the rack either stay out of the way, or compliment the crown. This is why I have so far avoided added eyelets through the top of the fork crown- I like that big flat space, evoking early MTB styling. On a bike getting direct post mounted centerpull brakes this isn’t an issue, I just use the centerpull mounts for 2 upper rack mounts, but with the Cantilevers it gets stickier, and my next 3 customers have asked for cantis. Is a well built three point rack really something that is just for 5 or less lbs, or am I overthinking it? I’d love to be able to keep building these without losing sleep over my pals losing teeth, the 3 point is just easier to integrate into the cantilever equipped lugged dinosaurs that I love making.

These bikes aren’t “mountain” bikes but they aren’t restricted to the road. These riders will likely load these racks with weigh ranging approximately between 6 and twelve packs of liquid, (a twelver of cans weighs 13 lbs) or that weight in camping gear or food on a quick stop at a grocery store. I know I do. I’ve loaded mine with multiple 6" 4x4 timbers. Racks will get overloaded eventually, if not by the first owner of the bike, the second. All of my customers end up up camping/touring with their bike, even if they didn’t order it for that.

On a few of my frames/racks that have racks and cantis I’ve built the rack so it mounts to the midblade eyelet and to the canti stud, but this can lock the customer into using that exact canti model forever, since different models of cantis sit higher or lower on their stud and my racks aren’t adjustable. I also found this set up to be more prone to brake squeal so I’d like to avoid it.

I’ve heard a few anecdotes of broken front racks that were supporting wire baskets that were ridden heavily loaded on rough but not crazy terrain. I’ve only ever seen the small VO ‘rando’ style racks fail myself, in my retail bike shop days, and those were also likely heavily loaded (like a 12 pack of beer weight). Usually these failures were on racks that used the separate bendable slotted or drilled ‘tange’ to attach the rack to the fork crown. Everyone that sells the nitto front racks seems to have stopped saying “just strap a basket on it and live in paradise” and now says “don’t put a basket on it or overload it!!” . On Crust’s website they state the weight limit of one of these Nitto racks as 4.5 lbs. If I’m build racks to carry more than that should they be 4 point mounted?

I see a lots of other builders making racks that just use a single pass-through bolt at the crown, and plenty of these bikes are advertised as rough road randonuer bikes - how to do you talk to customers about weight limits? Or is the pass-through bolt design actually just so tough that if done right it’s not a risk?

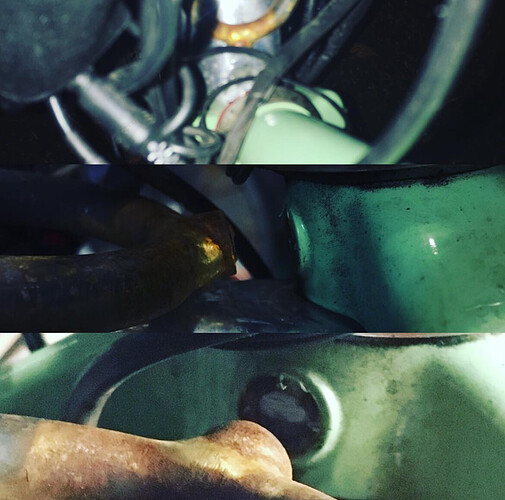

Here are a couple pics of the rusty old prototype on my daily. Single pass through bolt at the crown. I’ve ridden it loaded with 15lbs off road plenty and I can find no signs of stress/damage. Super stiff.

Here is a more recent platform rack (ignore the separate pannier rack), still using a bolt that passes through the fork crown. This rack has the added cantilever stud mounting point that I’d like to avoid… This rack design feels super burly and it leaves the crown nice and visible. I also add a large washer that is brazed directly the the pass through bolt on the rack end, to help stabilize that and reduce any flex side to side.

While I value the form of the 3 point rack, is the increased strength of the 4 point worth it for the function side? Your thoughts pls. Thaaaanks.