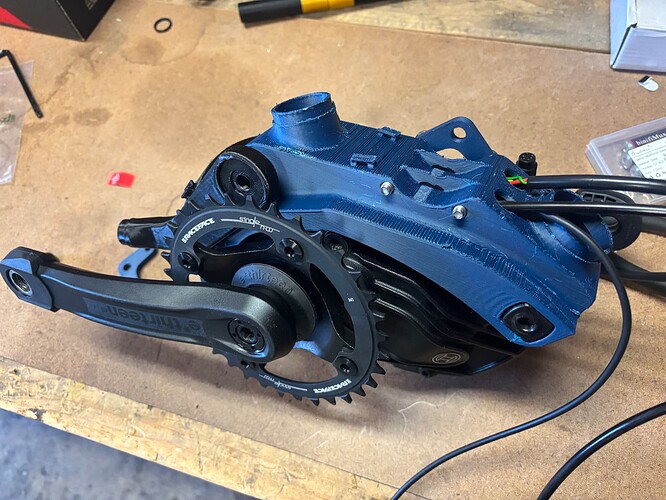

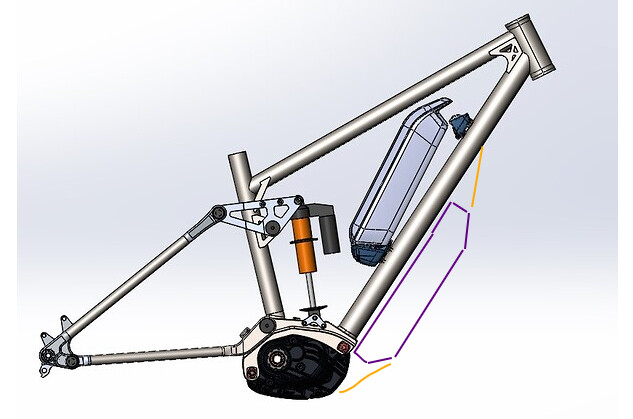

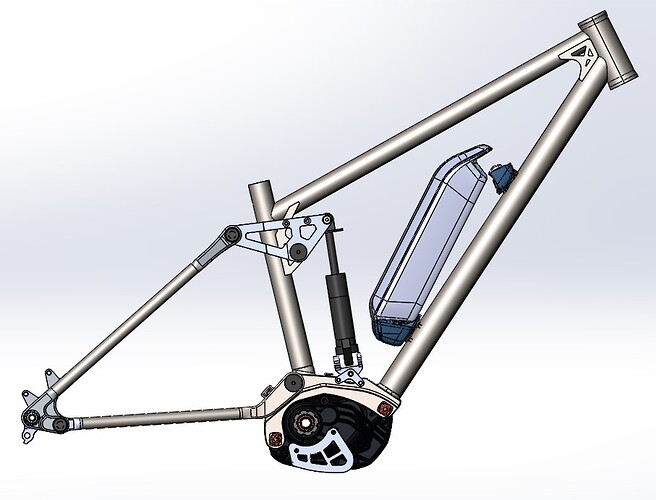

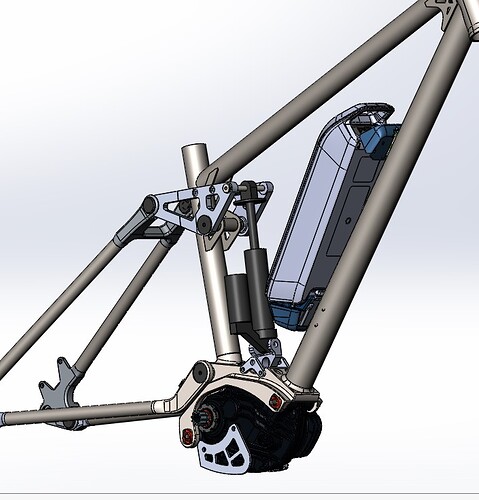

Well it’s getting cold in this hemisphere so that means less riding and more building. I’ve got the design mostly complete for my to-be-named bike. Highlights are: Bosch line CX motor, 170mm rear, 180mm front travel, 27.5/29” wheel, with a pretty standard Horst link design. I’ll be leaning on 3D printed 316L for the motor node and most pivot junctions. I’ve already got the motor so I’ve been printing plastic prototypes to check clearances and make sure cables can fit. Looking forward to getting this one going.

I have one or two concerns. Don’t get me wrong I love the design, but the battery is too far forward IMO. I know it needs to be like that in order to clear the shock but you could also consider a horizontal shock mounting system with a yoke, which would mean the weight of the motor, shock and battery are closer to the rider’s centre of mass (for example, the lapierre GLP3.) When you’re making quick adjustments on the bike you’re essentially pivoting it around that CoM, so weight further forward makes it harder to move, and leads to rider fatigue.

A fair point. I debated that layout for a while but my frame fixturing setup would make that challenging for me. With this setup I can get the shock mount and main lower pivot in one go on my current jig with fewer machined parts at the cost of the CG being a few millimeters higher.

mounting the shock upside down and designing around that constraint can in some cases get you a little bit more space to lower the battery on the downtube. Have done that before.

I like your design, it looks good! I’m guessing you’ve considered this, but flipping the battery to the bottom of the DT could be an option, with the benefit of an easier to reach water bottle location and the potential to lower the TT at the ST to make things more compact. You could always 3d print some plastic armor to protect the battery and flow the lines together a bit:

Fair do’s, that’s a very valid reason to choose the design you’ve chosen. It’s looking really good, so keep us all updated when the metal parts start coming in ![]() looking forward to it!

looking forward to it!

Also like Spencermon said, there may be room to move the battery down a few mm if you mount your shock with the reservoir at the bottom and rotated like the frameworks bike? All you’d need is to change the shape of the shock mount slightly to accommodate a little clevis that fits a DU bushing inside, although that might not work as you already have a divot there for the shock.

I’m loving all this feedback. Thanks everyone! I will play around with some things in CAD for different shock layouts and check battery specs to see if it can be hung in that configuration. Luckily I live in the desert so I won’t be spraying the battery with water from the from wheel often if mounting the battery under the tube is the best way to go.

I was also going to mention the Frameworks shock mounting layout.

Pic for those that don’t know it. Sideways and upside down.

Since I couldn’t sleep, I worked on this a bit. The kinematics don’t change too drastically with the shock flipped, just makes things taller which I have room for since I am only making one size of this frame. The battery is able to come down a few cm which is nice and I will have a bit more room for a tube in front of the battery which is another bonus.

I will 3D print the shock extender and see how things fit before spending money on this. Thanks again all!

So much clearance. Might as well be a mile. I will start buttoning this up and ordering the metal prints and machined parts. Metal tubing is already on its way.

I test fitted the bash guard and it fits nicely. I 3d printed the entire rear triangle and I’m glad I did since there are a few tweaks I need to do for the for the stainless versions. Pumped to get the parts in.

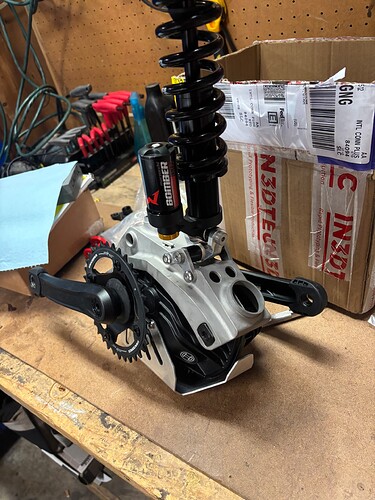

The parts from In3DTec are here and I am pretty much done with machining and printing my fixture parts. My tubes are here and the motor fits nicely into the “node” (that’s what Bosch wants to call it) which was one of my biggest worries because that was expensive to have printed. Now I have to get my fixture all set up and I can start welding! You can probably see some odd features on some of my 3D parts. I am trying an experiment where I design sacrificial pieces onto the parts to help with fixturing that I can (hopefully) remove easily after welding.

I have the tubes cut and my jigs all setup. I didn’t notice until too late that my 44mm hole saw is wobbling so it made some over sized holes. So I will have to order new DT and TT and a new hole saw which is annoying. I could probably make the DT and TT work but I am not a good enough welder to do so reliably. It looks like my built in fixturing is lining up nicely. The real test is how straight it is after welding.

Looks awesome!

The hole saws always wobble a bit and coped joints after hole saw require some cleanup to the mating surface with a file in my experience. They can be touched up on a lathe slightly if you have one.

But back to your problem: I bet you can file the crotch of the joints a bit (evenly as to not change the angle you cut) and get to an acceptable fit. Assuming the tubes aren’t already too short! ![]()

Thanks for the tip! Unfortunately I cut the head tube miters first and didn’t check them very closely then cut the other side to length. Now if I clean up the miters to make them fit, they will be too short. I should have checked the head tube miters more closely before cutting the other side. Oh well, at least it wasn’t titanium ![]()

At least now you have tubes for some future bike (that you’ll have to make)

Is it an issue if you lose a couple mm off your frame reach?

I am sure I would not notice if I decreased reach a few mm. However I already ordered the new hole saw and the new tubes and if I mess it up again I will definitely shorten the reach ![]()

Muuuuch better. New hole saw made me feel like I’m good at this ![]()

Actual welding will hopefully start soon ![]()