This spring I’ve been working on a new CX bike. I went with modern CX geo, keeping the BB a little lower and the HTA a little slacker. Some might call it an all-road bike. The tubes are a mismatch of Columbus and BFS, with Long Shen LR28 flat mount dropouts.

All hand tools in my shop, I traced the miter templates from bikecad onto the tubes. I’m pretty pleased with joints, and getting pretty quick with the files too.

I went chainstays first on this build, I had been building front triangle first. I think I’m a full convert to the chainstay-sub-club. I don’t have any of them fancy clearance checking tools, so on go the cranks and wheel.

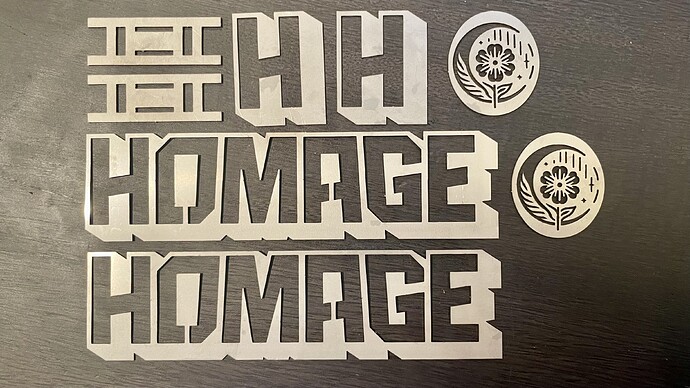

I’m trying out some laser cut badges and logos, hopefully I can get them to wrap around the tubes nicely. I taught myself how to braze finally, I had been using rivnuts and tig brazing with silicone bronze for all the bosses and guides. I picked up a small MAPP torch as recommended on the forum, it worked great for these little details.

All tacked up, ready for welding. It had been a couple months since I picked up a torch, you can see the pile of practice joints I used to get the rust off.

I should be wrapping up welding this week, then dropping it at the LBS for reaming, facing and chasing. Then it’s off to powder.