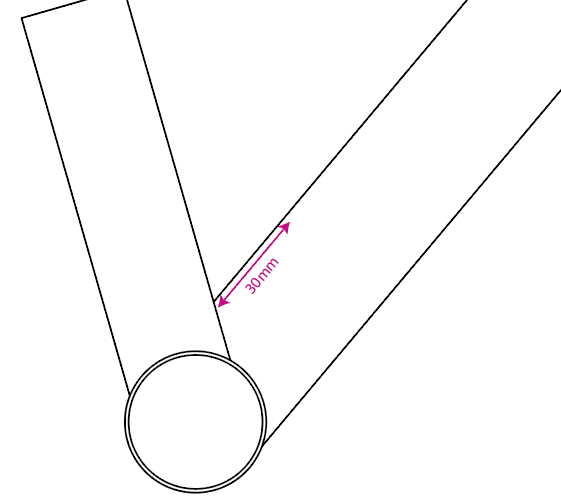

I had a quick question of how much of the butt to assign to each end of the top tube and down tube. Gravel bike for a 5’11" ~80kg rider! From reading other forum posts, the consensus seems to be to put the longer butt toward the Heat Tube joints for both tubes and 30mm is the minimum butt length.

-

Top Tube

** Zona Top Tube, 31.7 x 600 – Metal-Guru.com

** 60mm butt length, 110mm butt length

** Actual Top tube length per design is: 555mm. So I need to cut off roughly 45mm. Would y’all recommend 30mm (-30mm) butt at ST and 95mm butt at the HT(-15mm)?

-

Down Tube

** Zona Down Tube, 0.8 Butts 35 x 670 – Metal-Guru.com

** 125mm butt length each side

** Actual DT length: 653mm, Need to Cut roughly 17mm

** Cut all 17 at the BB/DT cluster and leave 108 butt length at the BB/DT and 125 at the HT/DT?

Thanks for looking! (Also if someone knows how to indent bullet points I would greatly appreciate the tip!  )

)

2 Likes

Part of your answer will be determined by your skill. If you aren’t familiar with controlling heat input then I’d opt for more than 30mm butt length – it’d be a shame to have the HAZ extend into the transition/thin section of the tube.

I try to keep at least 45mm butt at the ST/TT junction and at least double that at the TT/HT junction.

For the ST/DD/BB cluster, I try to keep at least 30mm beyond the ST/DT notch.

5 Likes

A good rule of thumb is minimum 50mm of butting. Some tubes/suppliers will spec a minimum, it’s usually around 2”.

More is more, but not at the expense of the other side. Also consider your heat input especially if you are new and learning, you should be mindful of running the absolute minimum butting spec and give yourself more room if you can. 30mm is not very much and your heat can easily surpass that if you are heavy handed with the torch.

For your TT scenario I would probably go 50/70, or better option would be getting a shorter supplied 560 TT for maximum butting, although it does depend on what the butting profiles are. Down tube I always prioritize more butting at the HT, top tubes the butting profiles tend to end up closer in length to each other as the tubes are usually shorter supplied.

Most tubes have a long butt and a short butt. Generally you cut the minimum amount from the short end, just enough to get your miter shape, and the long butt is the “adjusting” cut - bringing your tube to miter length. If your adjusting cut ends up too close to the butting, you ideally need a shorter supplied tube.

8 Likes

I’m dealing with a similar dilemma too!

I’m a smaller rider and want to use a 25.4 top tube and only has 450mm to work with…Shortest butted section I have seen is like 365 (340 too but hard to get) which leaves like 40mm of butt at each end.

I once saw a study done on strength loss at joint for TIG vs fillet brazing but forget where it is. Jits is that tig has a smaller affected area generally but you can neglect that a bit…

1 Like

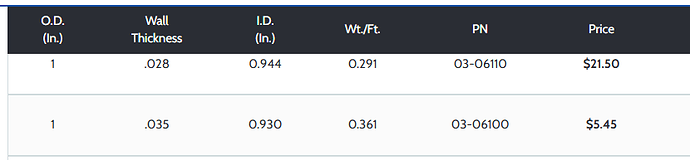

In your case I’d probably just order a length of 1" x .035" (25.4 x 0.9mm) straight gauge 4130.

A 600mm butted tube (0.8 - 0.6 - 0.8) weighs about 245g; a 600mm tube that has 0.9mm wall thickness weighs about 275g.

You can sometimes find .028" 4130 (that’s about 0.7mm) but as of today it’s almost 4x the cost in Freedum Units.

5 Likes

Thank you, straight gauge would be my last resort but for now I will see if I can play around with the top tube a bit so I’d have 45mm-50mm butt at each end!

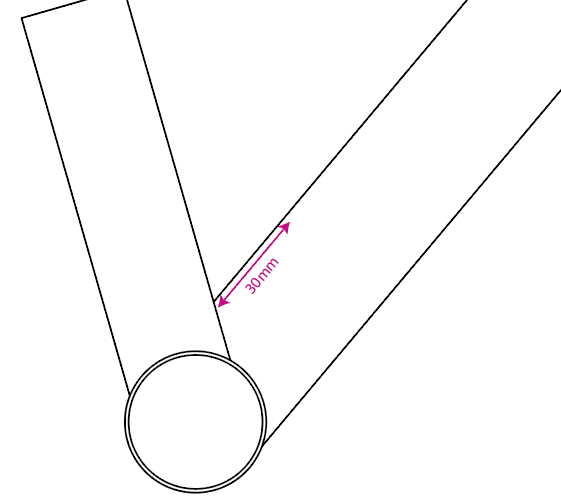

Is the 30mm valid for lugs as well? How long should the butt section extend beyond the tip/point of a lug?

Thanks!

![]() )

)