Hi, I’m Tim (he/him), I hand build steel e-cargo bikes in South Scotland, UK. I’ve got a small workshop and make big bikes in it. Ariel Bikes is me.

I’m a long time bike mechanic and I got into fabrication around 5 years ago when I acquired an e-cargo bike and realised how awesome and life changing they are. Basically I got hooked. I took some TIG lessons and started making things. Covid gave me loads of time to work on fabrication and welding and I’m hopefully better than when I started out!

I build out of steel because it’s tough and resilient and I want to make things that are useful for a long time and therefore have a more significant environmental / climate change impact. I ride cargo bikes, gravel bikes, mountain bikes, single speed, bmx and anything else that’s available. I crash with confidence and style.

I like this forum as it all seems quite fresh and forward looking and the information sharing and decency seems really nice. A nice little corner of the internet to know about. Thanks to all those who have put the time and effort into creating it.

Would like to see more people building practical/utility bikes and using the magic of e-bike motors to get more done.

And I’m very keen to learn more about 3D printing for workshop/work holding use and to get pointers on improving my poor 3D CAD skills.

And very happy to chat cargo bikes and concepts and to share the little I know….

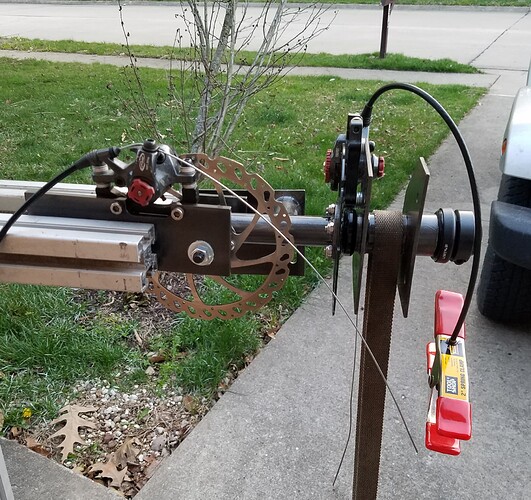

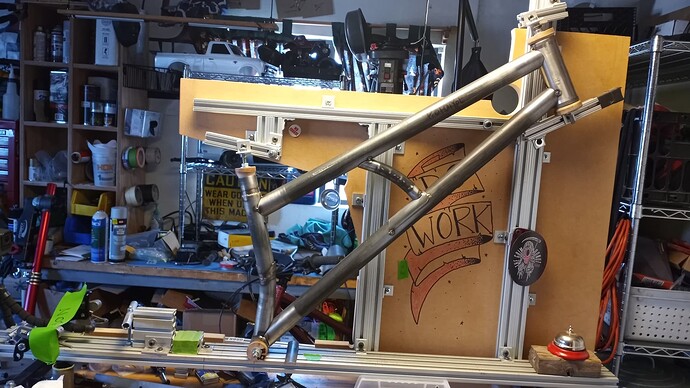

That’s me avoiding ice this winter. And some more bike pics: