I started sketching some tube profiles for the rear triangle. Need to carefully think how the loads act on the profiles and optimize stiffness in all directions. It’s going to be a lugged rear triangle as you have to go the same trouble making “lugs” anyways. A lugged setup is going to be light with carbon tubing and precise without any heat affected zones. Tolerances for bearings will be perfect.

Fusion has a great feature that allows you to sketch in 3D. It’s really useful in situations where there are connections and shapes to all directions (like the rear triangle). I plan to have a semi-rigid rear triangle where you can split it at the dropouts. This has two benefits as you can swap out longer dropouts to suit your riding and have a cutout point if you ever decide to use a belt drive.

Id like to chat to someone who has an idea of carbon profiles for this kind of setup. For now I’ll have to tease an AI about this.

Hey @Bucko , I chatted with Nico from Egerie and after couple messages he sent me some effigear models!

Looking great:

I’m currently sketching some profiles for the rear triangle. Need to find a person who has some experience on CF profiles that would suit this structure and some dealers that can help us pick the correct sizes. Anyways some assumptions have to be made as there isn’t just one correct stiffness for a rear triangle. This is why we prototype and iterate.

3 Likes

Progress check:

I already thought of optimizing our first prototypes rear triangle (machined 7075 al) since sourcing carbon fiber tubing for a lugged construction seems quite challenging. The cost for both are going to be almost the same if you count the jigs, assembly, etc. And its always easier to optimize than create something new. We will see.

My goal is to model symmetric parts to cut costs.

Idler will have 50-55mm chainline adjustment to house either pinion or effigear.

“Default” chainstay will be around 445mm and can be adjusted with swappable dropouts. Rear brake mount will be probably integrated to the dropout and default as 200/203mm.

I’m trying to figure out if there is a provider or an easy solution for belt drive idler pulleys. The idler should be around 14-19 teeth to provide enough antisquat so that the bike wont become a slug to pedal.

I’m amazed how little hardware I have to make or source for this design. Only the main pivot needs an axle and its counterpart. Rest of the stuff are basically sorted.

It’s shaping up. Planning to start manufacturing by may.

Ben from Kinetics here in Scotland makes a beltdrive idler. I think it’s for Brompton conversions, but you could ask him. Might be something you could modify/convert.

https://www.instagram.com/ben_kinetics/p/DQPIV5Lion6/?img_index=4

1 Like

Unless you want to roll-wrap your own, nobody does oval profile carbon tubing unfortunately. I asked the guy who builds athertons and understandably, he wasn’t at liberty to share their supplier.

Roll wrapping around an inflatable mandrel and then clamping it into a machined mould of your desired shape might be an avenue you wish to go down, you’ve got experience with the machining and getting the mandrel should not be too hard (I believe it is essentially a thick latex balloon.) This would give you full control of the tube profile too.

Yup, thanks for the feedback.

What came to my mind also was to contact Atherton, but I already anticipated this scenario from my crystal ball. I think Atherton earns their secrets and innovations for leading the industry in bonded frames department imo. For now I’m doing a preliminary design for a stiff fully machined AL rear triangle due to carbon being quite hard to source or manufacture.

Look at the Zerode G3, they use an adapter that takes a fixie thread to bearings, if you ask nicely, I’m sure you could grab one….. should be easy to make if you have the tools. I recommend looking at https://frameworkbicycles.com/; they are filament-wound tubes, but they do some top-notch stuff…. If you’re poor and crafty an axle looks suspiciously like a main pivot bolt.

1 Like

Hey, Thanks for the tips! I’m surely going to mod a M15 axle to fit a main pivot if the price of a custom one comes too expensive. You can probably get some cool nuts to fit the other end too without making your own. True motocross style!

For the belt idler pulleys I would need to use a 16 teeth as any bigger idlers compromise the antisquat.

Ah yep, you can always join the chain gang! Someone was making an oval belt chainring in the Discord group that could be worth hitting up. If in doubt, you can try a smooth roller and see how horrible that is or isn’t.

Back from the holidays, straight to modeling.

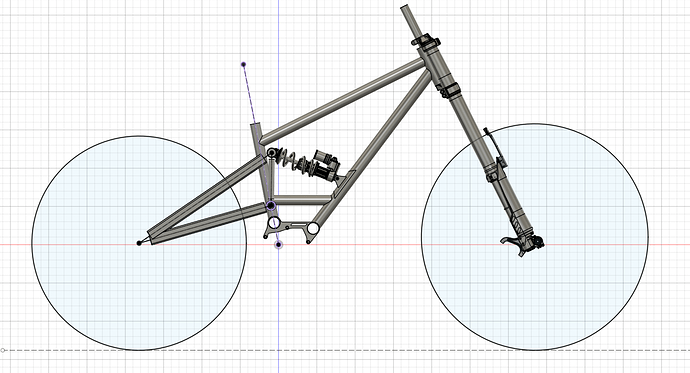

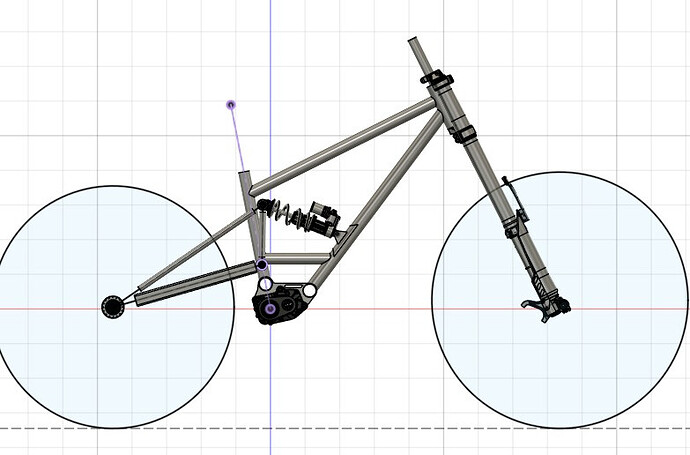

I got my hands onto some 29” wheel models:

The clearance with 445 chainstay and 29” rear wheel is quite tight as the seat tube is straight. Might be viable to reduce the shock stroke from 65 to 60 or use a longer dropout. This model is using 445 and the wheel is constrained 20mm upwards compared to 27.5” wheel which I currently have modeled to this dropout. A seatstay bridge would be nice, but only possible with 27.5” rear wheel it seems.

I wonder if anyone has a 27.5” rear wheel model?

A mullet setup could probably run a 430CS without the bridge I’d guess and a bridge with the current 445CS.

Next up is to model some swappable dropouts, and keep finishing all the other models.

2 Likes

Hi Tommi,

have you tried to change the parameters from your 29” wheel model to a 27.5” one.

-Thom

Hello,

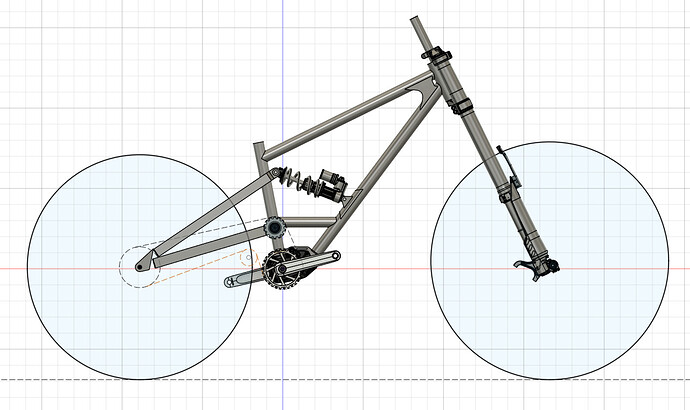

Some progress in modeling:

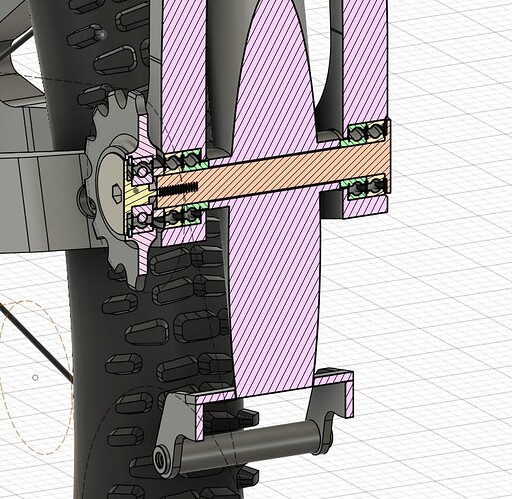

I decided to add double bearings to the main pivot:

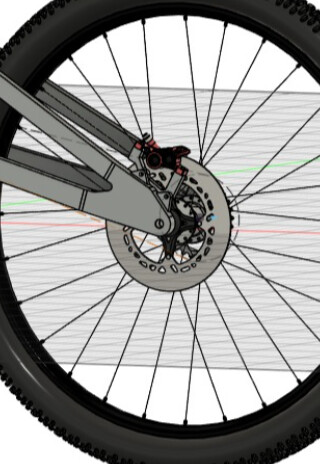

Also slimmed down the dropout area and added IS brake mount tabs:

Currently starting to speak to manufacturers for machining some parts and designing around their suggestions. Some pockets to the stays and fillets etc. I am really pleased with the looks of the bike. Models are also quite parametric, so I can go back and forth with dimensions.

Next time I post, there will be some finished models with all the intended details.