New bike time!

I’ts been approximately 2 years since we finished our thesis project at the university and graduated with a functioning product and a brand - Kovabikes.

We had a passion and used all of our efforts in making the best bike to suit our needs. It was a success. During the development of the bikes we had to sacrifice our time and put aside what we love the most - riding and enjoying the hobby. After we had graduated, we decided to take a break in development to spend time actually testing and enjoying the creation we had made.

2 Years forward to this day, we have validated that our prototypes are exactly what they were meant to be; A way to enjoy and have fun. More to the technical achievements, we have identified certain aspects of the bike that might need revising and things that were spot on from the first go.

Taking from the learnings, we are sparking a new chapter under the brand and seeking possibilities for producing these epic bikes with values that other riders share with us. Our aim is to first make the new revised prototypes before next summer and run real world testing. We also want to validate the results with a third party provider (e.g. iso-testing, efbe testing) so that others can also really trust our products. We want to highlight transparency and collaborating with you guys to make the best product for us riders.

Follow along because now you have a possibility to really be a part of the community we are building ![]()

Any suggestions, collaborations and thoughts are welcome and needed!

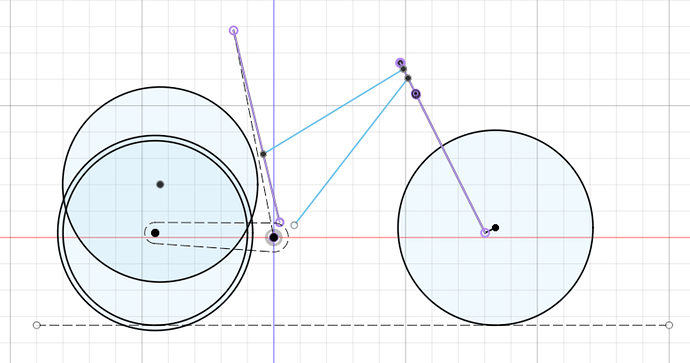

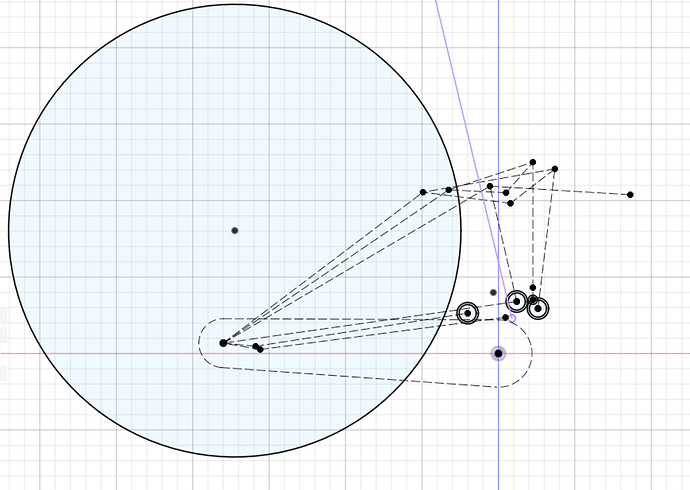

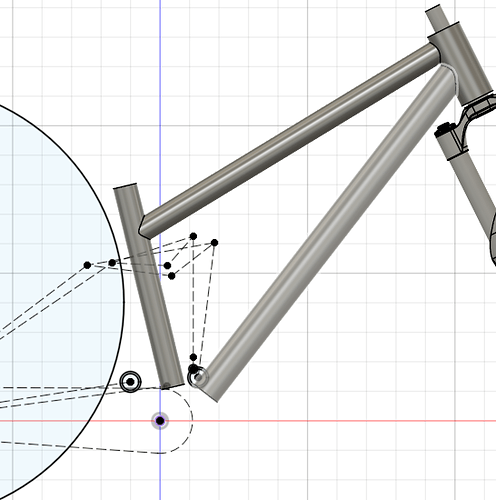

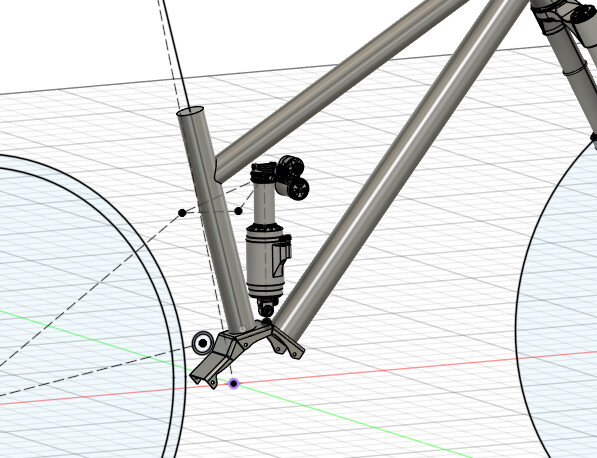

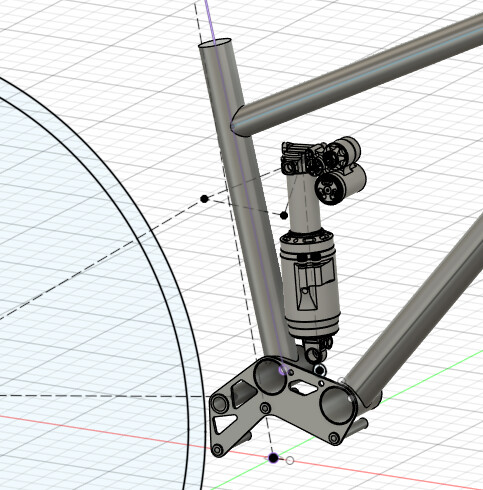

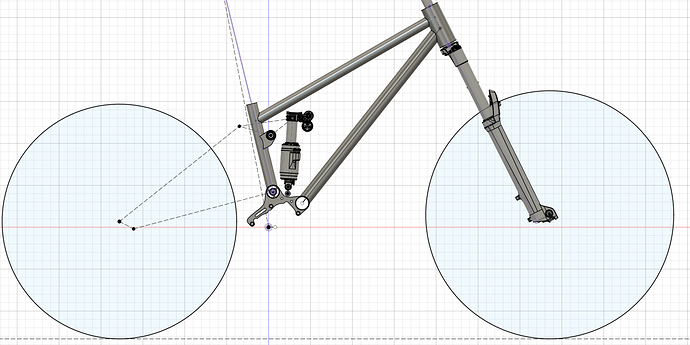

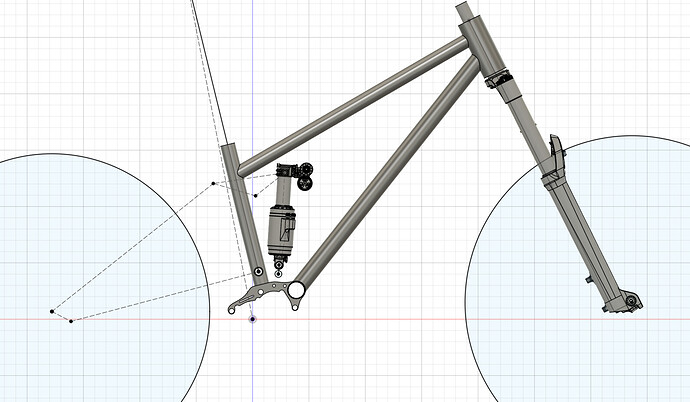

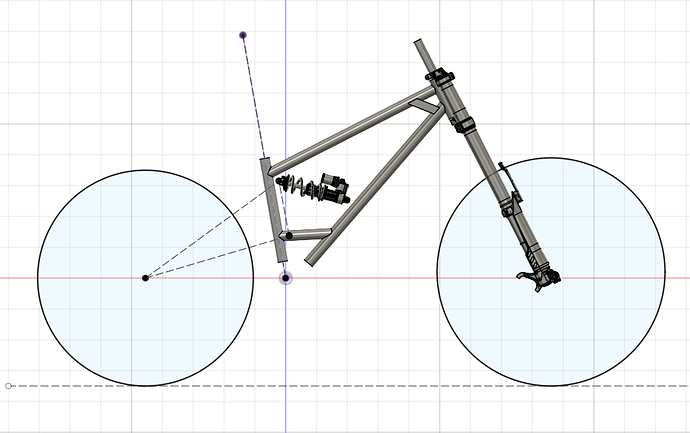

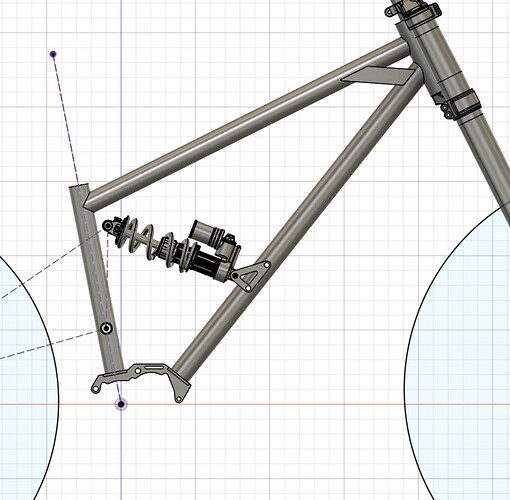

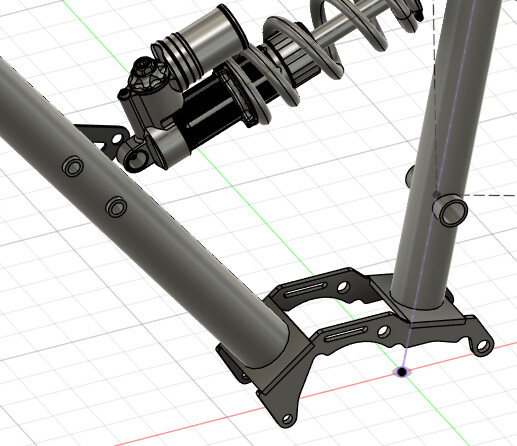

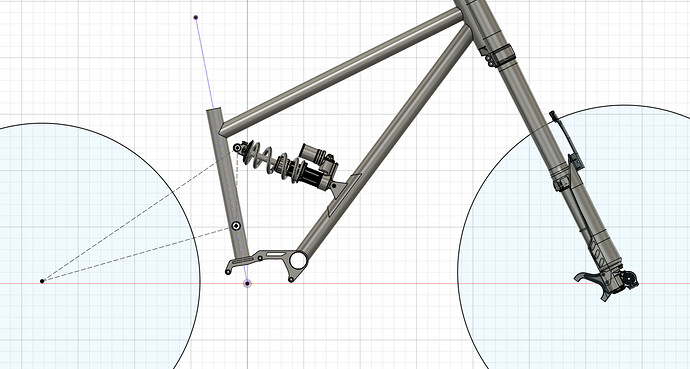

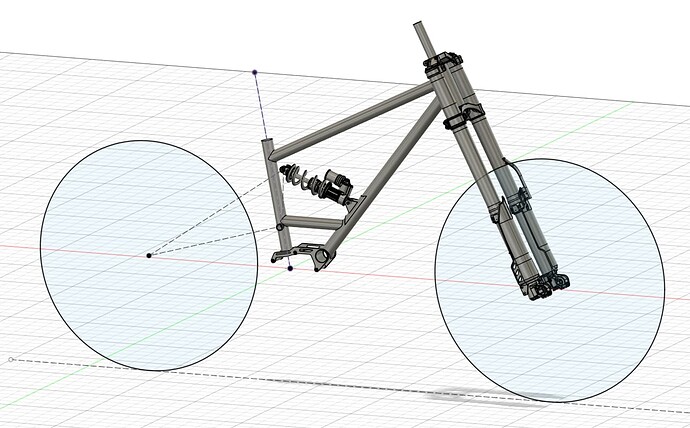

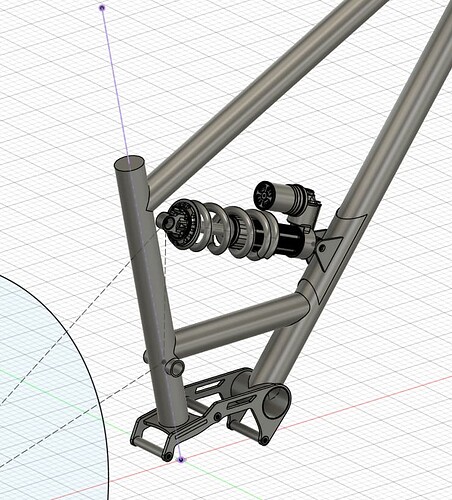

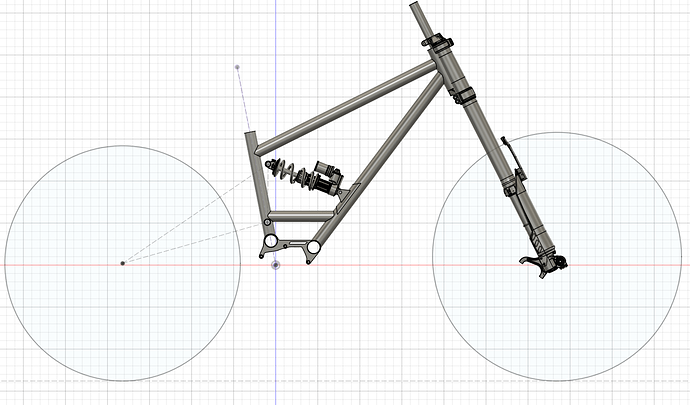

Here is the current form of our bikes, lets start enhancing it together to make it available for everyone!

We are thinking gearbox, optimized rear triangle, modularity, aesthetics and much more. Let me know what features would make the best bike for you? What do you value the most in a bike?