Hey all, I figured now is a good time to share the leaning cargo trike I’ve been working on. I have been stoked on cargo bikes for many years now, especially after becoming a dad and transporting my kid on a yuba long tail every day for the last 5 years. About a year ago, I was nearly done building a custom 4130 bakfiets when my wife crashed the Yuba on an icy road (thankfully after dropping off the kiddo). She was scared to ride for a while after that and I realized that a huge barrier to many people feeling safe on the roads (besides the poor bike infrastructure in the US) was the stability on slippery surfaces. Hence the leaning trike. I decided a steel trike would be far too heavy, so I decided to complicate the build even more by using aluminum. I have more than 50 steel fillet brazed bikes under my belt (well, I did 20 years ago), so this was a new challenge, having never welded aluminum before. This whole description is going longer than expected, so here are some pictures.

Why a leaning trike? Well, if you’ve ever ridden a non-leaning trike around a corner at more than walking speed, you’ll know. Or ridden on an off-camber road. I also wanted to keep the width around 24" so that it can fit wherever a bike can go, more or less.

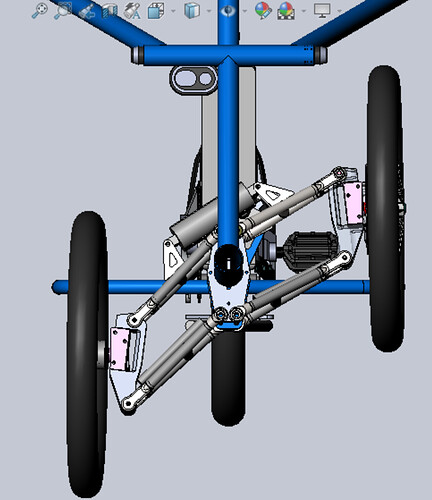

I should mention that even before my wife dumped the Yuba, I was messing around with trikes. I bought a trike conversion front end from a guy in Taiwan that was posting on Endless Sphere : https://endless-sphere.com/sphere/threads/leaning-trike-cargo-bike-front-end-kit.86613/

Despite some shortcomings, I was amazed at how well it behaved, and acted like a bike.

https://www.youtube.com/watch?v=Tj4r792USWc