I just finished my latest frame that I designed for smoothish higher speed trails. I decided to take the leap and design around short cranks and low BB. I ride single speed, so my plan is to have two bikes, one setup for slower technical trails with an easier gear (current bike), and one for faster smoother trails with a faster gear (this new bike).

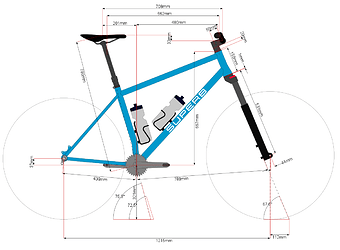

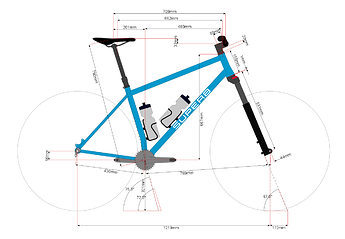

The frame stats (unsagged):

HA 66.25°

SA 75°

RC 405-445

FC 815

ETT 670

BB drop 74

BB height 297

120mm SID, 44mm OS

I’m 6’-1" with pretty long legs. I’ve ridden on 180s for the past 20 years and swear by the extra leverage for riding single speed, but with all the chatter about short cranks I decided to try it. I dropped my BB 22mm lower than my current frame from 52mm to 74mm. 165mm cranks make up 15mm difference, then dropped it another 7mm just to embrace the concept of a low BB.

I also reduced my fork travel from 130mm on my current bike to 120mm, and shortened the head tube from 115mm to 110mm. With cranks horizontal my feet are 22mm lower and hands are 15mm lower than my current bike.

I rode today on the type of trails I designed it for and it felt really good, especially balanced and planted in the corners. The short cranks really wind-up fast, which is nice coming out of corners. I definitely feel the reduced leverage on steep climbs, but didn’t have much climbing today. I’m looking forward to riding on the terrain I didn’t design it for to see how it stacks up. I have a feeling I’ll be redesigning my slow/technical bike after some time on this bike.

Other notes:

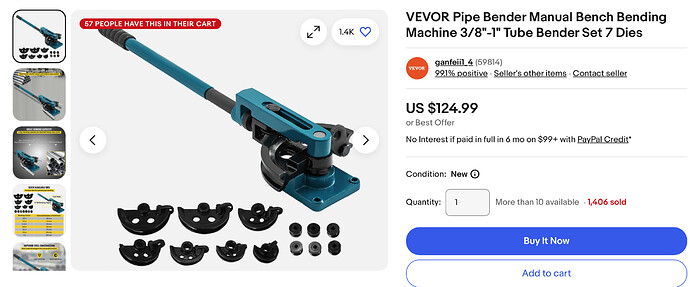

- I used Aircraft Spruce .035 x 5/8" for seat and chain stays. I bent them using a Ridgid 358 bender that I bought on eBay for $150. It worked quite well.

- I used @ben.land101’s yoke design. This is my fourth frame using a version of that yoke, it’s great in all respects.

- I designed dropouts that give me 40mm of adjustment so I can play with CS length.

- I still suck and welding, hopefully it won’t break.

Lot’s of valuable forum knowledge went into this frame, which I’m very thankful for!

-Garth