Hi all, I’m making plans to get started on my first frame, but I’d also like to make a custom fork because I like none of the available options I can purchase.

I don’t like how chunky carbon forks are and I want a 34mm head tube, and I don’t like that standard lugged road/touring disc steel forks like Surly’s still use 28x19 fork blades. I don’t like that those forks then look much skinnier than the 35mm downtube I want to use.

Would I be able to use MTB chainstays as fork blades? These to be exact: EDR286-16-09P-425V

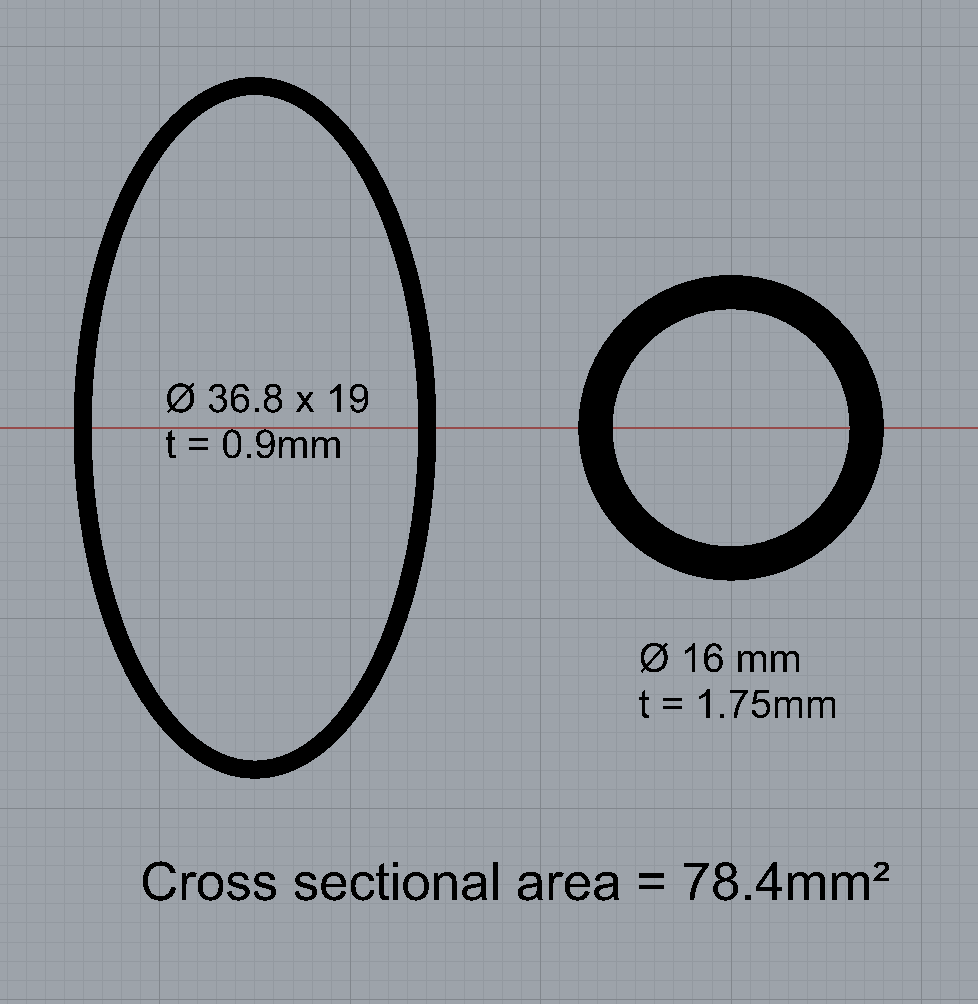

0.9mm wall thickness, 36.8x19 oval at one end and 16mm round on the other end. Theoretically that should be at least as strong as a 28x19 1.2mm thick disc fork blade, right? And I like that it would be about the same width as my downtube. I’m really all about matching the “optical weight” of everything on my bikes.

The plan is to build the frame with 3D printed 316L lugs, and I could also design a lugged fork crown to be printed in 316L with plenty of wall thickness, like 2mm(?) for safety. Also printed ends at the bottom and a rear-styld flat mount, integrated into one print with the brake side dropout.

Also can I use the Columbus Spirit lightweight 2/1.2 28.6mm steerer? It’s for an allroad bike and I’m a pretty light rider at 65kg.

1 Like

I used chainstays for forkblades a few times. Worked fine

2 Likes

Do you know the wall thickness of the blades at the dropout end? One concern would putting a disc brake mount on such thin blades. Even a fully integrated mount can cause a stress riser further up the blade. Good chat about that here if you missed it.

In that thread there’s a recommendation for tandem stays the Nova used to sell to be used as disc fork blades but they’re butted from 1mm down to 2mm (!) at the small/dropout end.

1 Like

Just did the quick math and if you swage a 36.8 x 19 x 0.9mm oval tube down to 16mm round you end up with a wall thickness of 1.75mm. Should be plenty beefy.

Personally I think thinner blades look better on a steel forks though. The fork matching/blending with the HT/DT is very much a modern/carbon aesthetic and could look out of place on a lugged frame. Especially with the add additional “visual mass” of the lugs! Could look good too just not something I’ve seen.

3 Likes

I think some of the real experts could give their opinion here, but from what I’ve heard it sounds like forks are more difficult to build than a frame… and can be pretty catastrophic if you get it wrong.

I’ve built a few frames and have some fork parts sitting as I’m but sure I’m 100% on the brazing skill needed.

I don’t know if they are more difficult, just that failures cause more damage so you need to have your processes dialed.

If the tube fits the requirements, there’s no reason a chainstay can’t act like a fork blade. You may not find a crown that fits the blades and dropouts might not fit as expected in the case of plug or socket dropouts. It is important that you are 100% confident in your joining methods. IMO That means making a handful and cutting them up to make sure you’re consistently getting full penetration etc.

2 Likes

Yes I totally agree. I’d probably even feel better about it if I also build one to break it, and also break an existing fork to compare it to. A bit more wasteful than I’d like but I’m not sure I’d be fully confident in my fork if I don’t do that.

This formula works pretty well. In the example below I used a typical 24mm chainstay with a 12.5mm tip and .7mm wall thickness.

[(24.0÷12.5−1)×0.8+1]×0.7=1.22 mm

1 Like

@Hananas you could use teh Columbus MAX fork blade. It is a deeper section and a proven part. I’ve built a few disc brake forks using MAX blades and they have been zero problems. You can get both internal and external lugged crowns for them already.

1 Like

True but I don’t like the way they taper to a smaller radius as the trailing edge, from a visual standpoint.

Did you check Reynolds Fork Blades? Drop an email to us and will send a list…

Fair. I prefer that look myself. Gives a hint at an aero shape and hence performance. Good thing we have choices.

I don’t think you’ll have any issues with the tube you have selected. It will make for a very stiff fork though.

1 Like

I recently got a Reynolds fork and I do like the blades on that but I haven’t been able to find anything about current reynolds fork blade offerings. I’ll send you an email because I am interested!

1 Like