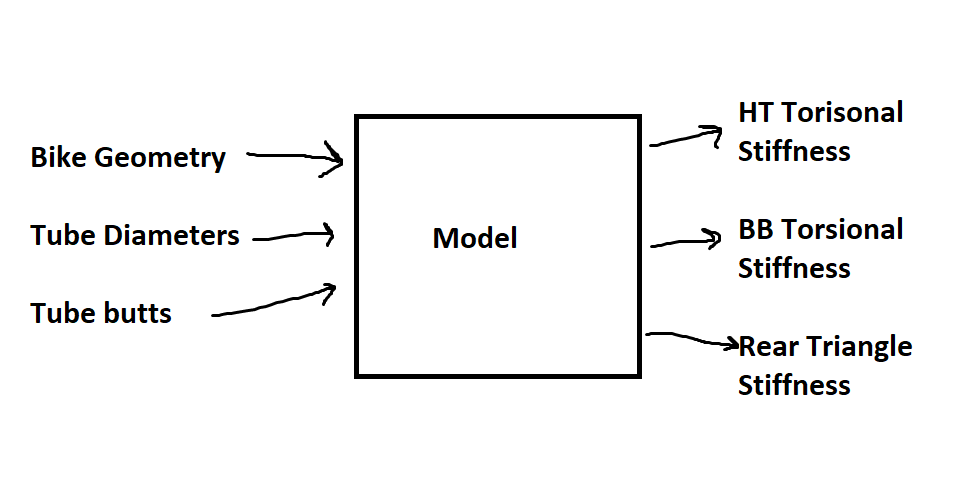

Wouldn’t be great to have a model:

I have slowly been pecking at this holy grail model with analysis, but I think its time to start refining the analysis with some real-world datapoints.

Stiffness, Diameter, Wall Thickness

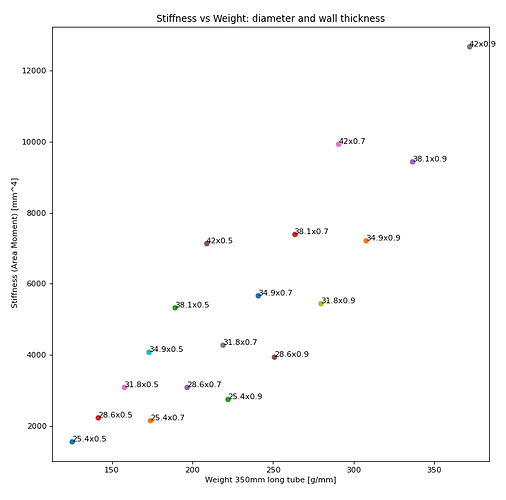

I coded up a quick analysis that compares the stiffness to weight of different tube diameters and wall thicknesses.

One important note: the calculation is for straight tubes with different wall thicknesses, no butts. How this analysis translates to butted tubes is up for debate. I can see arguments for both ways:

- most of the stress happens in the thick butts

- the tube is mostly the thin butt (by length)

Either way, the absolute numbers may not represent butted tubes, but the relative relationships should follow the same trend.

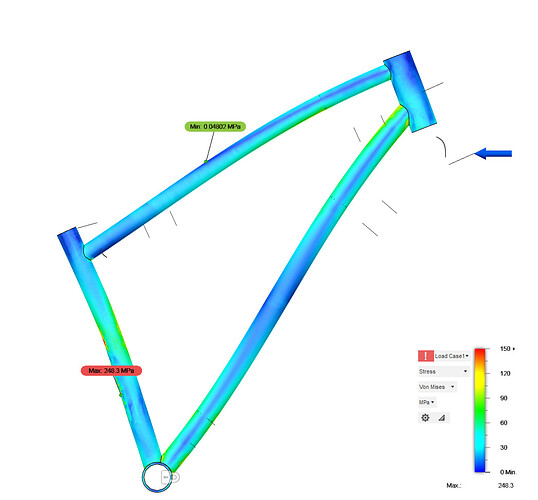

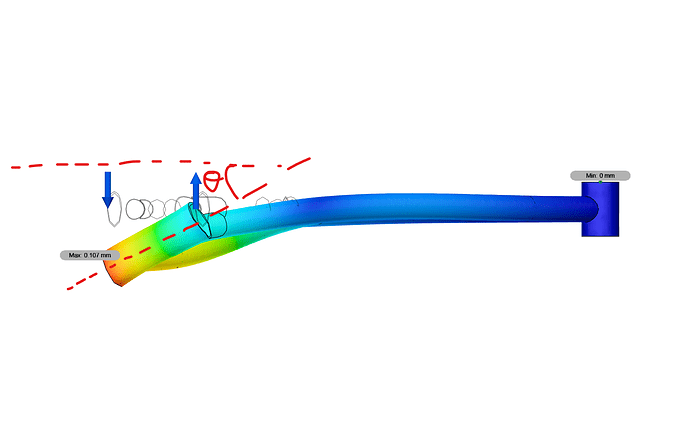

In front impacts, the end butts experience the most stress and strain:

Analysis:

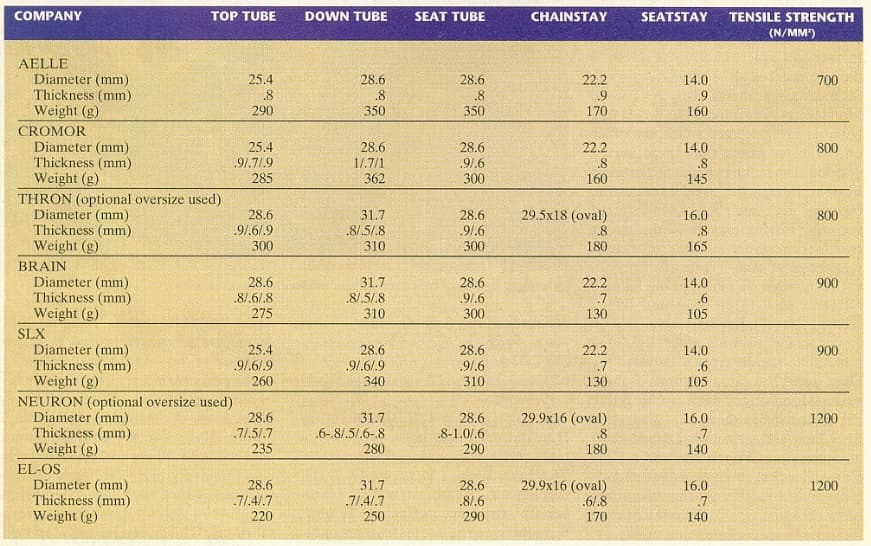

I generated this diagram that shows the stiffness vs weight with a parameter sweep of diameters and wall thicknesses:

Example:

Let’s look at a 34.9x.7 tube:

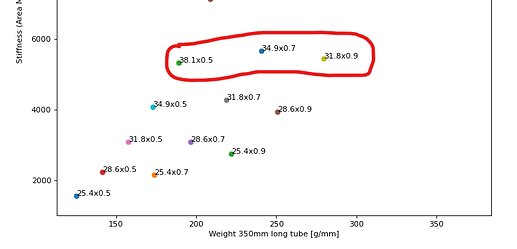

The 38x.5, 34.9x.7, and 31.8x.9 tube share the same stiffness

| Tube | Weight | Diff |

|---|---|---|

| 38x.5 | 173g | +0g |

| 35x.7 | 240g | +67g |

| 32x.9 | 280g | +40g |

BFS has an nice selection of 38mm downtubes:

| Tube | Butt | Weight |

|---|---|---|

| Velospec | 38x747 | 405 |

| Tange | 38x969 | 475 |

| Tange | 38x1.0/.7/1.0 | 578 |

Personally, I would not feel comfortable spacing the Velosepc 38x747 tube. According to the analysis, a 35x969 tube probably has the same stiffness, and weights at most 30g more for the same length. The thinner tube will be more dent resistant and easier to work with.

Conclusions

I think the current conventional wisdom is that fancier butted tubing results in better “ride quality”. But I think the ride quality people feel is a less stiff frame (which IMO is a good thing). Less stiffness can be achieved by using smaller diameter tubes with thicker butts.

There are some other real-world considerations:

- Larger diameter tubes are easier to dent

- Thin wall tubes are easier to dent

- Thin tubes are harder to join, which is the majority of the frame failures

- High quality tubes (heat treated and extra butted) have better QC (in our experience)

Unanswered Questions:

- Does ride quality = frame stiffness (and visa versa)?

- What bending mode contributes to ride quality the most?

- torsional stiffness at the headtube?

- torsional stiffness a the BB?

- vertical stiffness of the frame?

- What work has been done to understand steel frame stiffness?

What questions do you have? What have your experiences been with tube selection? What tubes would you like to see?