Thanks I watched the video.

I guess then the only practical difference is less strong steel is easier to bend and work? Like Zona and Spirit…

Then, the stronger steel is more dent resistant with the same thickness.

This was in a past issue of Bicycle Quarterly.

it’s fortuitous to have sentiments like these come back into the public’s eye, though the salient point is nothing new or novel. the ride of a bicycle (what someone atop supposedly feels) is hardly tethered to the material or its diameter or gauge or shape or country of origin. it’s always about design. after that, quality of construction will check a box or four. and before i get into the weeds, clearly a proper fit over and between the wheels of said bicycle is paramount.

the industry shoves a metric ton of marketing bullshit down our collective throats by way of advertising and race (related) results. buy this and you’ll be as efficient and fast as _______ . i never bought into this crap. i tolerated it when i was new because (mainly because) i didn’t have a calling card or any palmares to cite. but by the middle to late seventies it was game over for me. my tether was reached and i no longer believed the crap that permeated my trade.

the ride of a bicycle (assuming the rider fits it without compromise) is directly (and only) related to the frame design. obviously construction is key. but regardless of whether it’s welded, brazed, or stuck together with glue, or if it’s steel or not steel, or if it’s a set of modern tubes or something from the eisenhower years - what the rider senses, or feels, or discerns has to do with the layout and assembly so much more than the material used.

thank you for listening to my ted talk.

Amen!

ps sorry about all the editing.

my ipad and this site don’t understand each other that well!

When we get into bike tubing, there are some more practical concerns.

Forming and cutting a more basic tube (Zona) vs. a fancier tube like Velospec (not heat treated) is roughly the same. Heat treating is what makes things much harder to work with (literally).

For example:

- heat treated steel is more dent resistant

- high end steel generally has better drawing and QC (more accurate butts, cleaner tubes, etc…)

- availability of butt lengths and butt thicknesses

- cost

Here’s a blog post that summarizes the test:

and/or

No more questions now pretty much ![]() by fancier you meant specific butting on the Velospec right?

by fancier you meant specific butting on the Velospec right?

I was wondering who is this guy and how come he wrote “seventies” like who built bikes back then, then click on the profile… :o

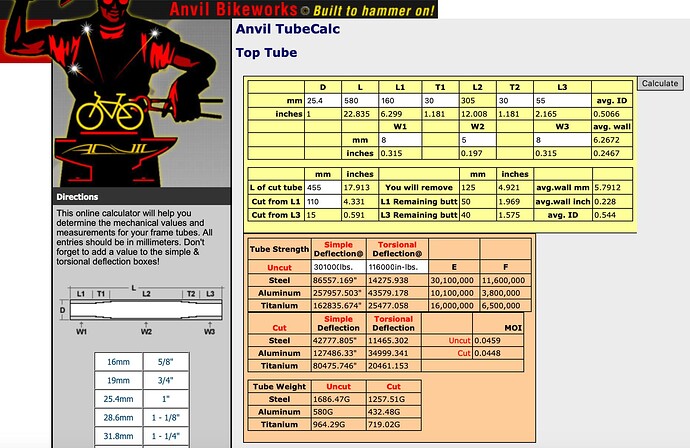

May I ask you what number should be put in for ‘Simple deflection’ and 'Torsional deflection for Uncut tubes?

That’s the load being applied.

I’m usually comparing tubes, so just put in a dummy number, say 1000, and see the % variation.

Some others here might have more realistic load figures to use.

All the best,

Dan Chambers

Imagine you’re playing soccer in the back yard and Ronaldo stops in to give you a few pointers! ![]()

![]()

Thanks Dan,

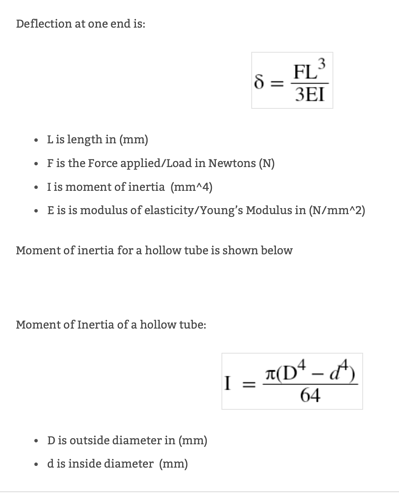

That makes perfect sense… Seems like the calculator is doing something similar to this?

I wonder to which use cases can this model be applied to?

For instance, I’m looking to see what’s the minimum of butt I need for my short top tube. It will be 40-45mm on each end on a 45cm TT (so~9%). I will account for strength loss in the. joints as well…

And…simple deflection should mean vertical (compliance) right?

First post! I use a spreadsheet for tubing butting and ovalizing and think others might be interested. The spreadsheet and instructions are now in the public domain. You can model anything from a straight gauge tube, double butted, or even a butted, tapered, and oval chainstay or fork blade.

Spreadsheet

Video Instructions

Bob

Thanks for this. I have something similar but not for ovalization. Can you provide the password for the protected sheets?

Sure. It is All-Road. I also included the passcode on the main page just above the web links. As you probably know, its essentially a one dimensional finite element analysis, in this case 50 finite segments.

Ovalizing is done by taking a round tube, find the perimeter, then ovalize the tube but keep the perimeter constant. It’s necessarily iterative (no closed form solution), so it iterated 50 tubes or whatever then did a regression best fit. That in the Ovalization Best Fit Data tab.

Bob

The best fit errors on Ovalization Best Fit Data tab were switched, thus wrong. The actual errors are more like 1%.