After the v1 was completed, I started to design a fatbike for me. I had a Trek Farley 5 before, which I mostly liked, but the geometry was a bit too traditional for me. The seated position is fine for longer days on the saddle, but most of my riding is on the local MTB / enduro trails in the winter also, so the short reach was something that was too different from my enduro bikes. Also, I had some knee pain occasionally, and my hunch was that the long 175mm cranks combined with the wide q-factor was at least part of the issue (I’m 170cm = 5’7”).

Also, the Farley 5 had 27,5 x 3,8 in the rear and 27,5 x 4,5 in the front. I often felt that the rear tire did bite well and had just enough float for me (on groomed trails with fresh snow), but the front tire was eager to wash out.

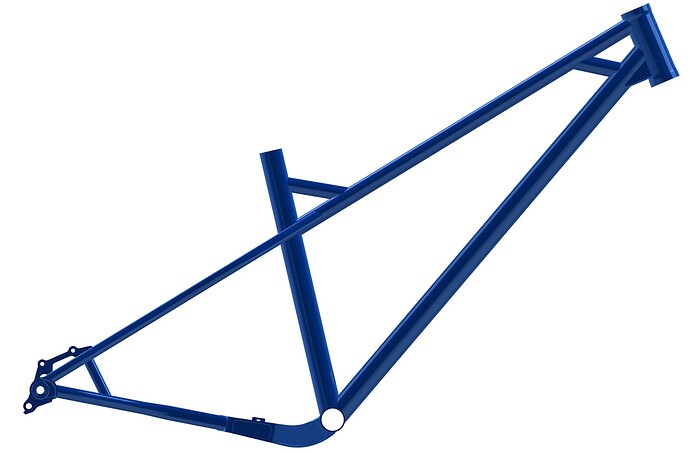

So the fatbike had to have enduroish geometry and somewhat narrow q-factor, with at least 26 x 3,8 tires.

The tubing is basically the same as in v1, straight gauge Docol R8.

Downtube: 35 x 1

Toptube: 30 x 1 ovalized to ~ 35 x 25 x 1

Seattube: 35 x 1 (with 3d printed PCTG insert to 31,6 id)

Headtube 45 x 1,5 (ends stretched with mandrel to 44 id)

Chainstays: 19,05 x 0,89 (front ends ovalized)

Seatstays: 15,88 x 0,89

BB: 38,1 x 2,11

Dropouts are cast steel UDH from Framebuilder Supply.

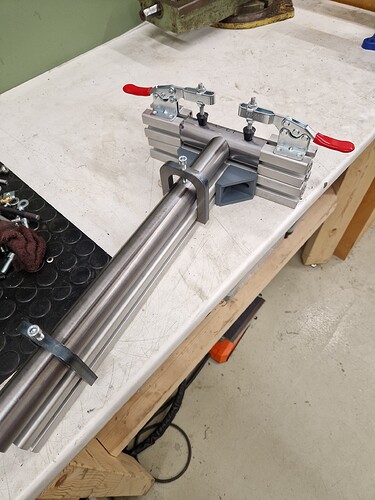

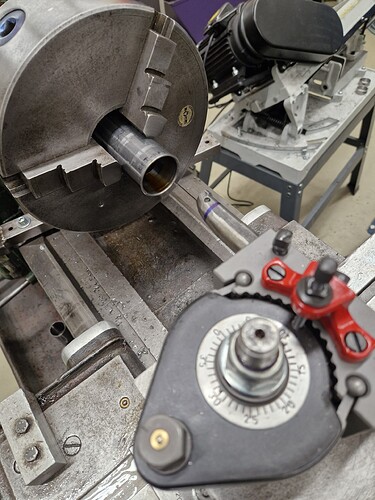

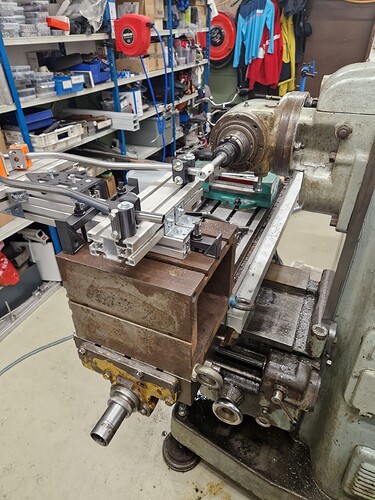

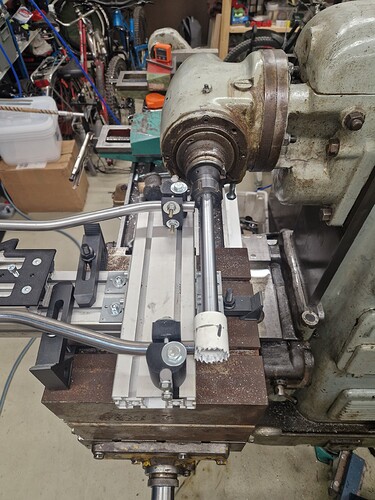

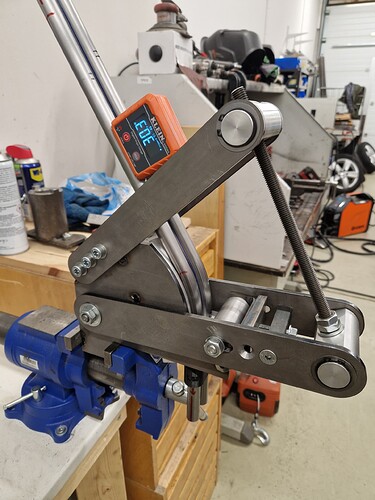

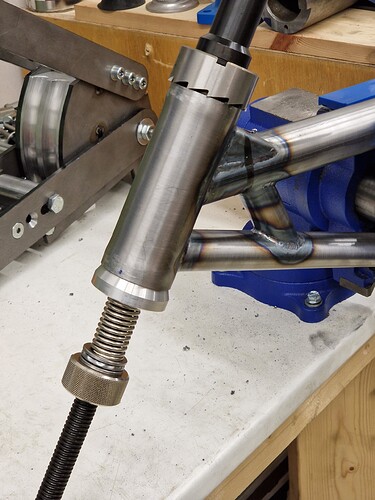

We rented a shop with Olli during the time, and I also bought a manual lathe and milling machine. So a lot of time was spent on setting up the shop and machines, and also repairing them. And learning to use the machines, since my experience with actual machining is close to zero. And of course, the framebuilders favourite, designing and building tools ![]()

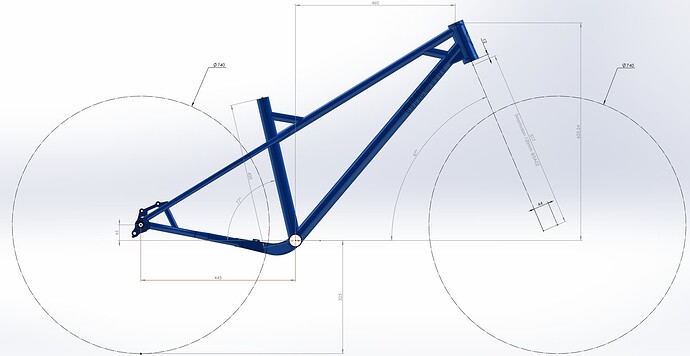

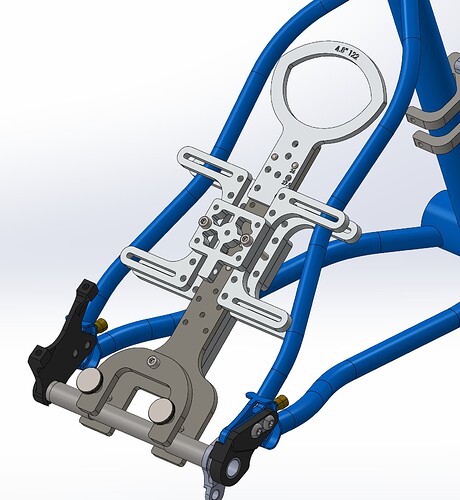

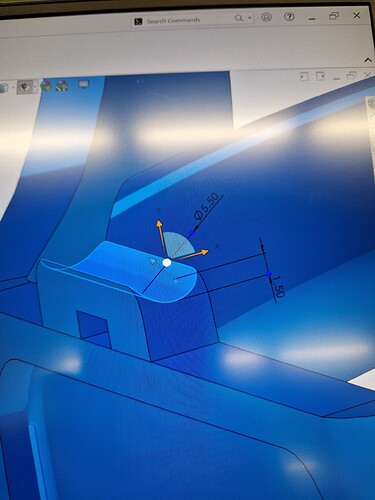

Few pictures from SolidWorks:

To be continued…