I was fully expecting to be a lurker and only occasional commenter.

However, given that I’m getting so much valuable entertainment and information from the forum, perhaps sharing my own bodgy efforts is the right thing to do. I’m not on insta or any other social media outlet, and have not genuinely shared on a forum in a long time.

Who am I? Short answer: Nobody special, currently residing somewhere in Australia.

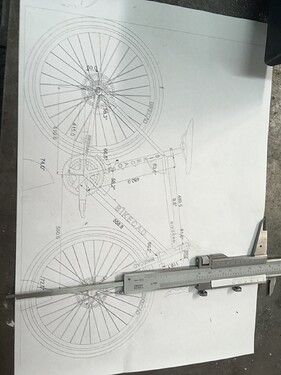

Framebuilding was something I wanted to do for a long time, but money, time and lack of local resources limited any progress beyond fascination.

Then around 5 or so years ago, the stars lined up and I took a course at ‘The Bicycle Academy’ (RIP). That is the extent of my formal ‘frame building’ knowledge, but I’ve picked up some general workshop and machining tidbits from friends along the way.

I do NOT want to do this for a job, perhaps not even as a side job. There are many reasons, but most of them are pretty obvious. I do this out of curiosity and to keep my hands busy.

Currently I’m using an oxygen/LPG setup torch setup with an oxygen concentrator (thanks to Doug Fattic for all that juicy info from back on the velocipede salon forum). Unfortunately, unstable living circumstances (moving around a bit) and finite disposable income have limited the build count to just three frames so far. Things should change this year though after what could be another big move, but I hope to explore some ideas in the coming future.

-Fil