Wish I had found this thread sooner! Lots of helpful ideas floating around.

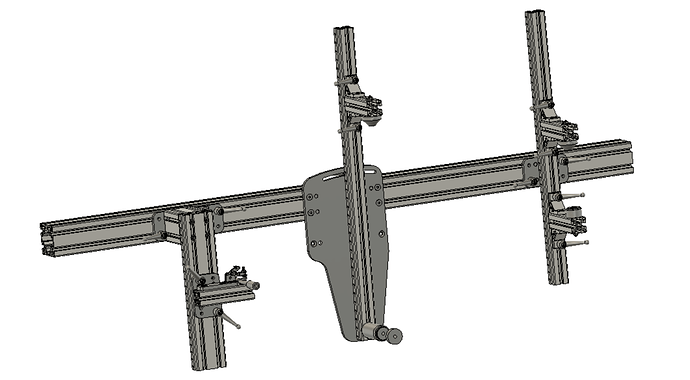

I’ve been working on a cobra style extrusion fixture for the past few days. I recently changed my main beam from 80x160 to 80x80 to save about $230. I designed around misumi 40mm extrusion since they have a ton of alteration options. The counterbored holes, end tapping, and thru holes for cone shoulder bolts are all available configurable alterations.

The only operations I’d have to do myself are milling the rear axle slot and reaming some holes in the laser cut plates.

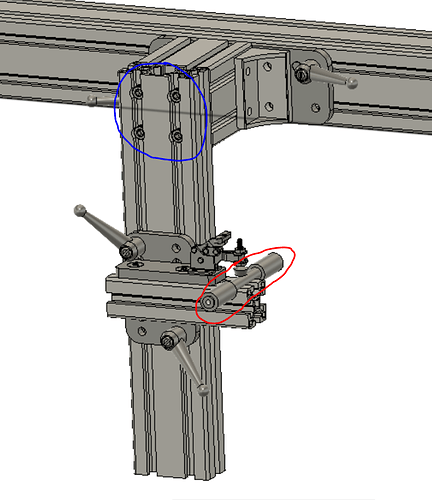

I have the pins locating the sliding plates on the extrusion in an attempt to reduce binding; 2 pins in a single slot, 3 pins for a double slot. I really like the idea of an adjustable key so I may change from the pins.

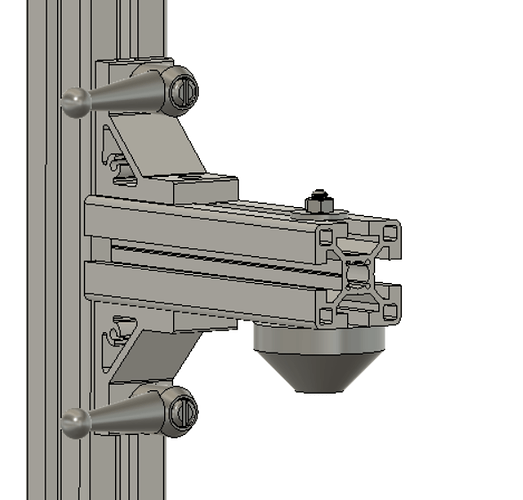

The small angle brackets from misumi have tab features to reduce coplanar slop. I may try using just a single bracket for the cone supports first to reduce cost and setup complexity.

I’d love to join in a group order of cones if that happens. I don’t have access to a lathe yet so I’d likely use some 3d printed ones for the interim.