Brodie’s use of the Dynafile is a bit heavy-handed IMO. It’s acceptable when the tubes are thick enough, and it helps to have large fillets. Helps in the sense of not digging a trough into the steel around the fillet edges. The large fillet does not help in terms of overall frame strength though, because the larger heat input and slower cooling of the big fillet result in a wider and softer tempered zone in the HAZ.

The strongest fillet-brazed bike you can make with thinwall tubes will have the smallest possible fillet, defined as the size where the braze is still stronger than the tubes, but only just barely. I recommend beginners arrive at this minimum fillet size experimentally (and seasoned pros alike if they haven’t already) by brazing samples and breaking them, like in a vise with cheaterbars.

With small fillets, the skill and eyesight needed to not thin the steel adjacent to the fillet becomes superhuman, so I strongly recommend using the “least powerful” option, whatever gives you the most chance to see a potential thinning of the tube and react before too much damage is done. Dynafile is not that tool.

I have smoothed miles of fillet, maybe literally. I was a tandem specialist, all with fillet-brazed steel, for over 20 years. I started at Santana in the '70s, not going to go over my whole CV but there at Santana I was the apprentice, so my job was to clean the fillets brazed by the other guys. That meant they had no incentive to lay 'em down smooth, and/or they just didn’t know how, because those were some seriously lumpy fillets. I used a carbide burr on a air-powered die-grinder (“rotary file”) followed by hand-sanding at first, until we discovered Dynafiles, which made my job easier or at least a lot faster. But those were thick tubes (1.0 mm) and large fillets.

At other places I worked, I was the guy making the whole frame start to finish. I hated the die-grinder step most of all — showers of brass micro-needles that stick in your skin and get in everywhere, even migrating through clothes to stick in your skin. Your significant other and pets will get them too because you bring them home. So I had a strong incentive to lay the fillets down as near to the final shape as possible. Also, just making the fillets smaller reduces the total amount of brass slivers on the floor.

I soon realized the Dynafile was too dangerous. No matter how good you get with it there will always be some thinning of the tubes. I could tell when a local FB at another shop got a dynafile, because his frames started showing up with deepish troughs in the tubes all around. My eye was finely attuned to see this gouging, by subtle clues in the reflection lines, and almost no one else could see it including apparently this guy down the road who must have been unaware of how badly he was weakening the frame. A couple who raced on the same team as me bought one of his. Not close friends but I was still disappointed. His asking price was lower and his waiting list was shorter. When they got it, they asked for my honest opinion. I pointed to where the frame was going to break, maybe kind of a dick move since they loved the bike, but it broke there after just a couple rides. He tried to get out of repairing it, saying they crashed it. I don’t remember what the final outcome was, but I never saw them on that guy’s bike after that.

So, no ( or extremely limited) Dynafiling. Rotary file followed by cartridge roll, then hand-sanding. And as little of all of those steps as possible.

Eventually I started offering the customers the option of unfiled fillets, just painted as-brazed, for a discount. OK a little shoe-shining with 80-grit, or 120 grit on superlight tubing, and the painter helped a bit with putty. I’d show them examples of fully smoothed and as-brazed, and they pretty much always couldn’t tell the difference, so of course they went for unfiled.

Pro tip: Leaving some work for the painter, if you have a painter you trust, can make the frame stronger. Not an option with powedercoat I guess, though I have no experience with that.

This freed me to use thinner tubing without worry of reducing the tube wall, right at the worst possible place, where it’s already weakened in the HAZ. Lightest I used was 0.6, somewhat rare on tandems but I used lots of 0.7 mm. Zero failures ever, unless someone’s bike cracked and they didn’t tell me (quite possible).

Summary: Until your brazing progresses to the point where you can lay them down “near net”, I strongly recommend using thick-enough tubing to compensate for the inevitable thinning of the tube at the fillet edge.

-Mark B.

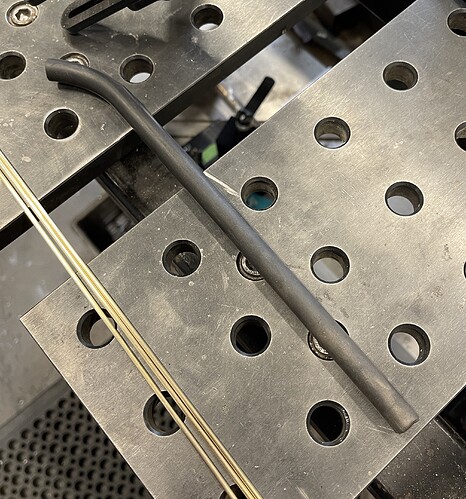

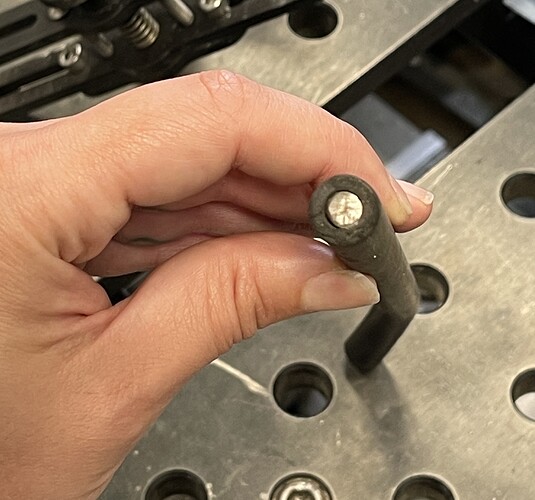

![]() (my files just dull very quickly)

(my files just dull very quickly)