Here is another good rim option:

A few updates to this project:

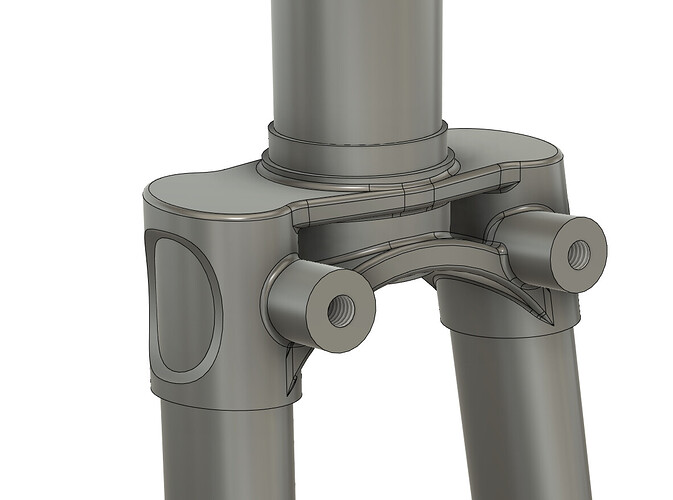

Cast Direct Mount Fork Crown

For fun I did a draft for a direct mount cast crown:

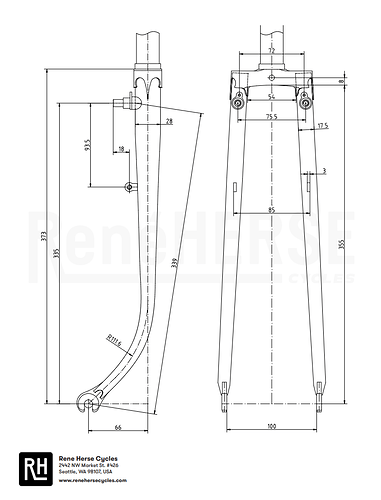

It is designed as a pure road bike fork, a narrow crown, 700x30 clearance, and a low 370 axle to crown.

I don’t really plan on building steel forks (but you never know), but I think they are an important part of the custom framebuilder multiverse

To give some perspective, I had a call with a Taiwanese trading company, and a the economics of a custom fork crown are roughly:

- ~$2k for mold

- $13 unit cost

- MOQ 100-200?

A ~$4k investment with a landed cost of ~$27/crown for 150 crowns. Maybe someone has a good idea of the framebuilder economy, but my guess is it would take 2 years to break even on that.

Direct Mount Standard Amendment?

According to an offline convo with @wzrd, they were successfully able to clear 700x30 + fenders{!} by bumping the bosses up 4mm and out 2mm. So this good news for the “standard”

Maybe the DM standard should be amended to DM51 (2mm wider) and 2-3mm higher posts. I will buy a wheelset and some calipers to test as well.

I’m really interested in this idea and the info from WZRD makes me even more interested!

But I’m wondering about development time + time to commercialize/land and how that relates to future gruppo availability (e.g. DA/Ultegra/105 w/out hydraulic braking)

In other words, if these were available within the next 6 months I could see speccing them on the next 5-ish builds. But if the time-to-landing is 12-18 months I’d be a little hesitant. Beyond that ends up being a wait-and-see proposition.

@ElysianBikeCo thanks for the support.

Definitely a chicken and egg problem going on. Assuming we had a design today - cutting mold, test samples, manufacturing, painting, shipping, would take 6-8mo.

But to get to that point, you would need $10k cash upfront. No independent builder can take on all that risk and fork (get it?) over that cash. The bigger financially backed companies have to play the same bike industry game and make titanium gravel bikes with internal routing.

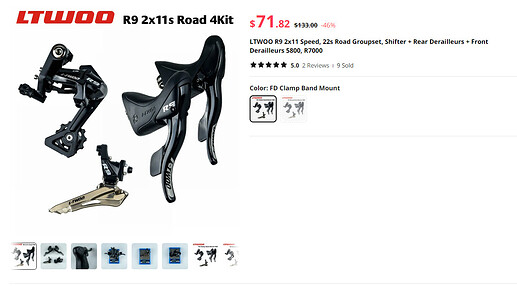

Groupsets

There is hope with Ingrid’s new mechanical shifter they teased at Bespoke. No idea if it is a hydraulic or cable pull brake.

There could also be a world where we convince Microshift to produce a higher-end SWORD 1x11 groupset or even reach out to a Chinese manufacturer to release a fancier groupset.

How it gets done?

As an individual, fronting the cost and risk of bringing a fork to market is huge, this is why no one does it. IMO, this is why framebuilders are at the whim of what manufacturers decide to make. The mainstream bike has diverged so far from the metal bike, that this will happen more often.

To get the project started, you would need 10 independent frame builders to commit to 3 forks ($1000). OR, you would just need to convince a mid-sized company like Crust, Rivendale, Wilde, Fairlight to produce a rim brake model using this fork.

IMO, the longer we wait to do these projects, the harder it will be to do them (groupsets, wheel availability, and bike trends)

What about BMX U-brakes? They’re already well established as a standard; they use the same mounting posts as Vs/cantis but higher up; plenty of cheap, mid-range and high-end options; can be set up centre-pull, side-pull or others (including double levers!); tons of tyre clearance; works with short-pull (road) levers.

I think BMX U-brakes are the same as Center Pull brakes?

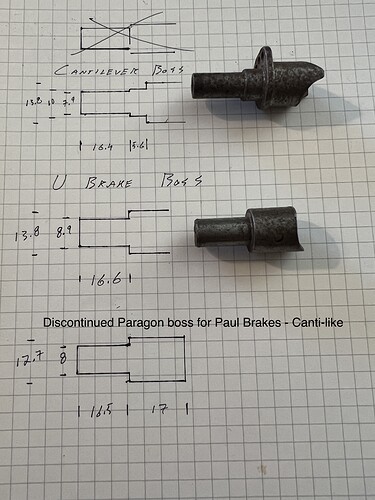

I did a bit of digging and came up with this chart:

| Front Brake Type | Boss Pitch [mm] | Boss Height [mm] | Clearance [mm] | Reach [mm] | Comment |

|---|---|---|---|---|---|

| Direct Mount (DM49) | 49 | 339 | 28 | 40-50 | Direct mount standard |

| Direct Mount Ratified (WZRD51) | 51 | 341 | 30 | 40-50 | Direct mount standard, but 2mm wider, 2mm taller |

| English Direct Mount (ENG68) | 68 | 337 | 44 | 40-50 | English’s proto direct mount gravel brake |

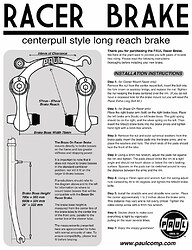

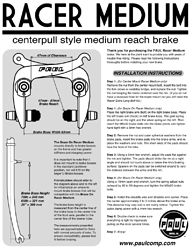

| Paul Racer Med | 63 | 340 | 35 | 47-57 | Short center pull |

| Paul Racer (Center pull) | 78 | 350 | 44 | 57-72 | center pull |

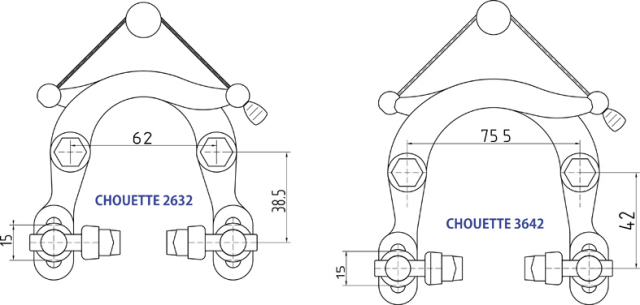

| Rene Herse (Center pull) | 75.5 | 335-340 | 42 | ??? | Based on a french standard |

U Brakes use a different, slightly larger OD, mounting post than cantilevers. I believe the Dia-Comp 996 specifies a 90mm post spacing but I’ve heard the classic 990 was meant for a little narrower mounting.

Center pull brakes (Like MAFAC and Rene Herse) use a slightly smaller OD post than cantilevers. Rene Herse specifies a 75.5mm post spacing.

Thanks for that, I had no idea, and no idea where to look!

Rene Herse is awesome enough to post some documentation:

75.5mm pitch spacing and between 335-339mm height (depending on fork offset).

That leads me to my next question, when people design for center pulls, do they use the Paul standard or the Rene Herse Standard? Is there a history why the two are so close, but not the same?

My read is that the RH standard is the old French standard and Paul derived his standard on the best location for his brake.

Why reinvent the wheel? ![]() Centerpull brakes like Mafac Racer/Raid, DiaCompe 750, and Compass/Rene Herse have been around for a long time and already solved the wide tire problem. Even normal cantilevers and/or V-brakes do the job well, too (I have mid-length V-brakes on my rando bike and they work great ATMO). I’ve tried the long-reach sidepull caliper brake (Tektro R559) on a 650B conversion, and felt the brake caliper had too much flex overall.

Centerpull brakes like Mafac Racer/Raid, DiaCompe 750, and Compass/Rene Herse have been around for a long time and already solved the wide tire problem. Even normal cantilevers and/or V-brakes do the job well, too (I have mid-length V-brakes on my rando bike and they work great ATMO). I’ve tried the long-reach sidepull caliper brake (Tektro R559) on a 650B conversion, and felt the brake caliper had too much flex overall.

-Jim G

My recollection here may not be entirely accurate but I believe that Jan Heine had some input on the original Paul Racers which initially were made in long reach and without a mounting plate. I think this was before Jan was making components and definitely before he was making brakes.

Initially Paul said there would never be a mounting plate but one later became an option as well as the Racer M medium reach brakes.

I think using the cantilever boss for the Paul Racer was not because the larger boss was better but because canti bosses were more widely available and because Paul already had the bushings, springs, and other hardware that is shared across the excellent Paul brake lineup.

Jan later made his centerpulls under the Compass then Rene Herse name. The brake bosses and location are the same as the Mafac RAID and the brakes themselves are very similar to the RAID.

You have to design for the specific brakes because they use different locations and different types of boss. The Paul uses cantilever bosses. The Rene Herse uses centerpull bosses.

That makes sense, thanks for the additional information.

Every day’s a school day! I always thought the posts were the same size, just located differently.

The Paul bosses are a lot bulkier than the French standard. This doesn’t matter for cantilever/V brakes, but with centerpulls/U brakes the boss crowds the area where the tire/fender needs to be.

Hahn Rossman

I would recommend reaching out to Ritchey. They designed their rim brake fork to push the limits of standard reach rim brakes to clear 30/32’s and I’m sure they would share the axle to brake mount measurement used.

I had several requests to make a similar fork for ENVE but there was just no way to justify the investment. I think it’s a hard sell for any company to invest in new rim brake products and would wager to bet we will see few if any new rim brake products come to market going forward. Current rim brake products will slowly be eliminated from product catalogs as demand decreases as well. (case and point of the DM eeBrakes)

Soon, aftermarket rim brakes will be the only ones available. If we look at who is currently making great aftermarket options, most are in the mid reach camp with the exception of Cane Creek. (I have a list of ALL aftermarket tubeless rims and mid+ reach brakes HERE)

I think you’d be much better off building a bike around standard mount mid reach with clearance for 35-38. A big reason for this is rolling resistance. We know a larger tire with the same casing is faster. Period. Going with rim brakes means you should be using alloy wheels which eliminate the argument for aerodynamic optimization. Leaving rotational weight as the only downside of going with a large volume performance road tire like the Pro One 34c, GP5000s 32c or RH BonJon Extralight 35c. (Also very excited for the upcoming Pirelli P Zero Race TLR 40c).

Cane Creek DM eeBrakes were without doubt the best solution for a standard reach with 30/32 clearance but sadly they are discontinued. Chris Bishop had been maxing out DM ee’s with custom steel forks for several years.

Bishop DM EE Bike Pics

https://www.instagram.com/p/BqNXB1ClCtU/?hl=en

https://www.instagram.com/p/CiAXbMhOwWi/?hl=en

https://www.instagram.com/p/CyVvpWqu1JU/?hl=en

https://www.instagram.com/p/CYo1hAAOkd-/?hl=en

https://www.instagram.com/p/CXlhFEXuqYh/?hl=en

https://www.instagram.com/p/CMAOL__FWl-/?hl=en

Bishop DM EE Custom Mount Pics

https://www.instagram.com/p/CKG_1c5lv6U/?hl=en

https://www.instagram.com/p/CCtUasbjZ85/?hl=en

https://www.instagram.com/p/B2RWi0ygHEz/?hl=en

https://www.instagram.com/p/BjunKNnn241/?hl=en

https://www.instagram.com/p/CZMySm1oW6W/

Here’s a great resource for DM Brake Specs if anyone needs it. It’s most applicable to rando nerds but has dam near every DM spec ever created.

You can find the specs for GrandBois centerpulls here: https://cyclesgrandbois.com/SHOP/gb_ch_m.html

thanks, everyone! Love it! Its great to see all these obscure standards that I never would have come across.

For the record:

Great thread. I’m more than a little interested in this topic.

@Daniel_Y I just realized there is some overlap between standard reach (typically 39-49) and mid-reach (typically 47-57) If you stayed the course of 357/358 brake height optimizing for 48mm reach, then you would effectively be building a frame that can accommodate all short and mid reach brakes AND clear at least 30c tires! The Standard and direct mount eeBrakes share the same geo so if builders are able to make the DM version clear 32 I have no doubt the standard version could clear as well.

Also, Looking at brake specifications, Most all brakes are redesigned to accept up to 28mm external rims. So there’s plenty of room to produce a modern aluminum rim that fits into current calipers. The Crust Rim Brake Rims are the widest I’m aware of at 23mm Internal / 27mm External. I also have the complete list of every rim brake rim available on the market HERE

Cane Creek eeBrakes / Reach: 39-49 / Max Rim Width: 28mm

Sram Force AXS / Reach: 39-49 / Max Rim Width: Unknown

Shimano Dura Ace 9200 / Reach: ?-51 / Max Rim Width: 28mm

Shimano Ultegra 8100 / Reach: ?-51 / Max Rim Width: 28mm

Shimano 105 7000 / Reach: ?-51 / Max Rim Width: 28mm

I’m all for producing a new rim and brake optimized for wider tires but it would be important to me to offer more universal compatibility. If/when these new rims and brakes aren’t available or service parts aren’t available in 20 years a customer can still get parts for their bikes.

I think a new 48mm reach optimized frame and caliper (43-53 reach) would be the way to go over proprietary direct mount standard. That would also allow you to sell the calipers after market.